You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Powdercoating update.... now cheaper!!

- Thread starter Beagle333

- Start date

Well... like I said, I'm out of touch. I've been casting off and on since about 1970, which almost puts me in the "curmudgeon" category  , but I had never heard of this.

, but I had never heard of this.

Questions...

When you do a push through sizing, does it wear the paint off appreciably? Pics, before and after?

Any reports on paint being left smeared in the bore? Honestly....

Any change, better or worse, in velocity from those who chrono?

I'll be doing some "searching" on this topic, but it's good to get you guys' reports...

They ARE purty, though, aren't they?

Questions...

When you do a push through sizing, does it wear the paint off appreciably? Pics, before and after?

Any reports on paint being left smeared in the bore? Honestly....

Any change, better or worse, in velocity from those who chrono?

I'll be doing some "searching" on this topic, but it's good to get you guys' reports...

They ARE purty, though, aren't they?

There's not really a difference.

Before:

After:

They don't scratch in the die unless you are using a lyman and there's a burr on a lube hole or some such, which you probably would have noticed from scratches on lead bullets. Most guys use a Lee push thru die for sizing, and that is recommended, just for the ease of it and not having to worry about keeping pressure off your lube screws in a lubrisizer. Some do use their Star though (with no pressure on the lube lever).

It doesn't leave any paint in the bore. The only thing left is some dust from whatever powder you were using. It isn't actually "paint", the way you think of paint... it is a very fine powdered polyester and it melts and "cures" over the bullet, providing a 1/1000 of a inch thin "jacket" of very thin, very slippery polyester coating.

In my testing (and it agrees with others), it is a bit slower than regular lubed bullets. In my .45, it is about 4 fps slower and in .357 loadings in the 12-1300 fps range, it can drop somewhere around 40-45 fps from regular lubed bullets. The current presumption is that it is more slippery and doesn't build as much back pressure as lead bullets and doesn't get as much initial kick. That is up to your individual interpretation though, as I know of no pressure testing that has been done. There is no concern over this small velocity drop in pistol bullets and many are still using it and testing to see what kind of effect it has on longer rifle shots.

Before:

After:

They don't scratch in the die unless you are using a lyman and there's a burr on a lube hole or some such, which you probably would have noticed from scratches on lead bullets. Most guys use a Lee push thru die for sizing, and that is recommended, just for the ease of it and not having to worry about keeping pressure off your lube screws in a lubrisizer. Some do use their Star though (with no pressure on the lube lever).

It doesn't leave any paint in the bore. The only thing left is some dust from whatever powder you were using. It isn't actually "paint", the way you think of paint... it is a very fine powdered polyester and it melts and "cures" over the bullet, providing a 1/1000 of a inch thin "jacket" of very thin, very slippery polyester coating.

In my testing (and it agrees with others), it is a bit slower than regular lubed bullets. In my .45, it is about 4 fps slower and in .357 loadings in the 12-1300 fps range, it can drop somewhere around 40-45 fps from regular lubed bullets. The current presumption is that it is more slippery and doesn't build as much back pressure as lead bullets and doesn't get as much initial kick. That is up to your individual interpretation though, as I know of no pressure testing that has been done. There is no concern over this small velocity drop in pistol bullets and many are still using it and testing to see what kind of effect it has on longer rifle shots.

In my testing (and it agrees with others), it is a bit slower than regular lubed bullets. In my .45, it is about 4 fps slower and in .357 loadings in the 12-1300 fps range, it can drop somewhere around 40-45 fps from regular lubed bullets. The current presumption is that it is more slippery and doesn't build as much back pressure as lead bullets and doesn't get as much initial kick.

While cast is a bit different, this is the same thing that is noted with most coated bullets. IF the coating is slicker, your going to realize a velocity drop using the same load for a coated verses non coated. In most cases, with rifles anyway, though if your velocity range is in a specific accuracy node, then it only takes a small adjustment in the powder charge to bring it right back up.

When I worked a lot with moly I found this to be true almost across the board with everything I tried it in. Each load needed roughly a two grain increase, depending on what powder, to get the velocity back into the range the non coated bullets were running.

Personally I haven't tried the coated cast just yet. Interested, absolutely, even have a jug of powder sitting in the loading room. But, I am working up loads for 5 different revolvers right now in preparation for hunting season this fall. Once I get those dialed in, I might venture off into the shallow end of this pool. I have two of what I feel will need to be three alloys worked out to my liking so far for my hollow points, and with a little time and testing the third should come along pretty easily. If just coating them would accomplish my needs I would be all over it, but there is this nagging pressure issue to get a bullet up into the 1400 -1500'ish fps range, that I simply don't think it will help with. Still have to have the alloy stand up to being slapped in the rear by 35-50K of pressure first.

If you are looking for 1300-1500 fps out of a handgun, I assume you are using a slow burning powder like H110 or AA#9? I have loaded some WW bullets up to around 1200 or so, non gas checked, with little to no leading at all in my Blackhawk .45 Colt. I imagine that these coated bullets will allow at least that.

I'm anxious to try them out. I no longer have that Blackhawk, but I regularly shoot a WW alloy hollowbase Lee bullet out of my Marlin 45-70, and it's hitting about 1150-1200fps with no leading at all. I plan to cast up some of these and PC them, to see if there is any difference in velocity or accuracy, as this is a "known" load.

I PC'd a few random bullets I had laying around on the bench a couple of nights ago. I didn't get a terribly good coating (even/consistent) on them, yet they turned out pretty nicely. I just stuck them on parchment paper on an old cookie sheet in the oven at 395 deg for 20 minutes. Worked like a champ. All I have to do is figure out how to get a better coating on them before "cooking"...

I just stuck them on parchment paper on an old cookie sheet in the oven at 395 deg for 20 minutes. Worked like a champ. All I have to do is figure out how to get a better coating on them before "cooking"...

I'm anxious to try them out. I no longer have that Blackhawk, but I regularly shoot a WW alloy hollowbase Lee bullet out of my Marlin 45-70, and it's hitting about 1150-1200fps with no leading at all. I plan to cast up some of these and PC them, to see if there is any difference in velocity or accuracy, as this is a "known" load.

I PC'd a few random bullets I had laying around on the bench a couple of nights ago. I didn't get a terribly good coating (even/consistent) on them, yet they turned out pretty nicely.

Rangefinder

New member

Well, I tried this new "shake-a-shake" method today, and took it a little off the deep end.

I had a little time to kill, and cut a crude, smooth-side cavity with the intent of running it through my CVA Kodiak Mag inline .50 cal. Why? For giggles... I was curious if it could be done. Then I decided to give the airsoft method of PC'ing them a try,

Well, here is a couple cooled. Not exactly pretty, but considering I went from beginning to cut the cavity to cooling the PC'd bullets in about an hour and a half, I wasn't expecting runway performances. Truth be told, it was cut in a piece of random scrap block I had laying around because I wasn't going to waste good stock and a ton of time on something that I had no idea would even work. They're .503 on the drive band and come in at 275gr. with dead-soft.

Well, then I had to shoot 'em... After all, that WAS the whole idea.

Getting them started took a little bit of a 'pop' with the starter and I slicked the outside with an ultra-thin swirl of bore butter. But once the lands bit, they slid down the bore really smooth and seated over 60gr Pyrodex RS. I wasn't really so much interested in accuracy as I was how they would ride the bore being PC'd with no patch or wad, and only enough bore butter to start them in the muzzle. Two shots from the shoulder at 50 yards hit 1 3/4" apart and 2" low of dead-center with nice round holes. Bonus--the goofy things appear to be accurate, too! But now I'm gonna have to spend some time cutting a real mold instead of winging it with a piece of scrap!

Next came the real quest---how's the bore look? Well, I went in the house, pulled the breech plug, and shoved three dry patches through--no water, no solvent, no nothing. They were crudded just like I would expect with any muzzle-stuffer. Then I glanced down the bore to see how bad it was leaded or smeared...

Granted, my phone isn't much of a camera, and wasn't agreeing with me when I told it to focus down the bore of my inline. But I think it shows clearly enough that there is no leading--bright, shiny bore and nice, crisp lands.

I did a so-so effort at trying to dig the bullets out of my berm and haven't located them yet. On the next run I'll put some effort into recovering a couple. I'm really curious how they look now.

SO, after violating a few smoke-pole rules, I seem to think PC'ing is viable for muzzle loaders under certain applications with great potential!

I had a little time to kill, and cut a crude, smooth-side cavity with the intent of running it through my CVA Kodiak Mag inline .50 cal. Why? For giggles... I was curious if it could be done. Then I decided to give the airsoft method of PC'ing them a try,

Well, here is a couple cooled. Not exactly pretty, but considering I went from beginning to cut the cavity to cooling the PC'd bullets in about an hour and a half, I wasn't expecting runway performances. Truth be told, it was cut in a piece of random scrap block I had laying around because I wasn't going to waste good stock and a ton of time on something that I had no idea would even work. They're .503 on the drive band and come in at 275gr. with dead-soft.

Well, then I had to shoot 'em... After all, that WAS the whole idea.

Getting them started took a little bit of a 'pop' with the starter and I slicked the outside with an ultra-thin swirl of bore butter. But once the lands bit, they slid down the bore really smooth and seated over 60gr Pyrodex RS. I wasn't really so much interested in accuracy as I was how they would ride the bore being PC'd with no patch or wad, and only enough bore butter to start them in the muzzle. Two shots from the shoulder at 50 yards hit 1 3/4" apart and 2" low of dead-center with nice round holes. Bonus--the goofy things appear to be accurate, too! But now I'm gonna have to spend some time cutting a real mold instead of winging it with a piece of scrap!

Next came the real quest---how's the bore look? Well, I went in the house, pulled the breech plug, and shoved three dry patches through--no water, no solvent, no nothing. They were crudded just like I would expect with any muzzle-stuffer. Then I glanced down the bore to see how bad it was leaded or smeared...

Granted, my phone isn't much of a camera, and wasn't agreeing with me when I told it to focus down the bore of my inline. But I think it shows clearly enough that there is no leading--bright, shiny bore and nice, crisp lands.

I did a so-so effort at trying to dig the bullets out of my berm and haven't located them yet. On the next run I'll put some effort into recovering a couple. I'm really curious how they look now.

SO, after violating a few smoke-pole rules, I seem to think PC'ing is viable for muzzle loaders under certain applications with great potential!

Rangefinder

New member

You might be onto something! I have only poked round balls down my smokepoles thus far. I wonder how red and blue and zombie green minie balls would go over at the Rendezvous though?

Well, they'd probably be a little upset at my inline, too.

Ok now your gettin my attention.

See I have this "Old Ironsides" cannon I put together as a kit back in my youth. It ain't much, but it would hit a 55 gallon barrel at 100yds pretty easily with the right person aiming it. Not to mention all the other things I came up with that would fit into the barrel.

I kept it in good shape and have considered several time bringing it up to the farm to play around with the grandkids. I haven't since it was always a pain to find the right sized patch to fit the round balls I shot. Not to mention that messy grease having to be smeared on them.

This might be something I COULD use, and get that ol thing off the shelf.

See I have this "Old Ironsides" cannon I put together as a kit back in my youth. It ain't much, but it would hit a 55 gallon barrel at 100yds pretty easily with the right person aiming it. Not to mention all the other things I came up with that would fit into the barrel.

I kept it in good shape and have considered several time bringing it up to the farm to play around with the grandkids. I haven't since it was always a pain to find the right sized patch to fit the round balls I shot. Not to mention that messy grease having to be smeared on them.

This might be something I COULD use, and get that ol thing off the shelf.

Cool!

Introducing:Zombie Balls!!!

A quick tumble of some Speer swaged .530 balls in some green powder I got from Smoke4320 and they baked right up. Not as slick as sprayed, of course, but really nice! I love em!

And coated completely, so as to be non-toxic if somebody smaller were handling them, if they were.... say... loading a small cannon.

Introducing:Zombie Balls!!!

A quick tumble of some Speer swaged .530 balls in some green powder I got from Smoke4320 and they baked right up. Not as slick as sprayed, of course, but really nice! I love em!

And coated completely, so as to be non-toxic if somebody smaller were handling them, if they were.... say... loading a small cannon.

Rangefinder

New member

Beagle, you're an animal! Those are awesome! LOL

New test:

My results with latex gloves.....

Some guys have been getting really pretty results from using the ASBBs in Ziplock bags and shaking/massaging it around and then picking the bullets out with latex gloves, and even smoothing the coating a little bit by gently spinning the bullets on the paper/foil with their gloved powdery fingers. I had tried it once before using plastic tubs and nitrile gloves and it didn't work well, but I wanted to give this a whirl.

Got some latex gloves. Dumped powder and ASBBs in ziplocks and massaged well. Bullets only took on lightly colored sheen of red or green. (I tried both colors) A lot of silver was still showing. And the gloves only rubbed more off of them, even though I dipped fingers in powder first.

So I dumped all into the CoolWhip bowls and shook good. Then tried lifting out carefully with gloves and smoothing out the bullets while they were standing on the foil. I spun them gently and tried to get a good coat. It just made it spotty. It worked exactly the way my earlier test with nitrile gloves did.

So I dumped em back and tumbled good again and picked out of CoolWhip bowl with sharpened pliers and sat on foil gently. Got good coat again.

Apparently, here with my humidity, in my static level of my work area, the pliers and CoolWhip bowl are still the best/fastest way to get a good shootable coat.

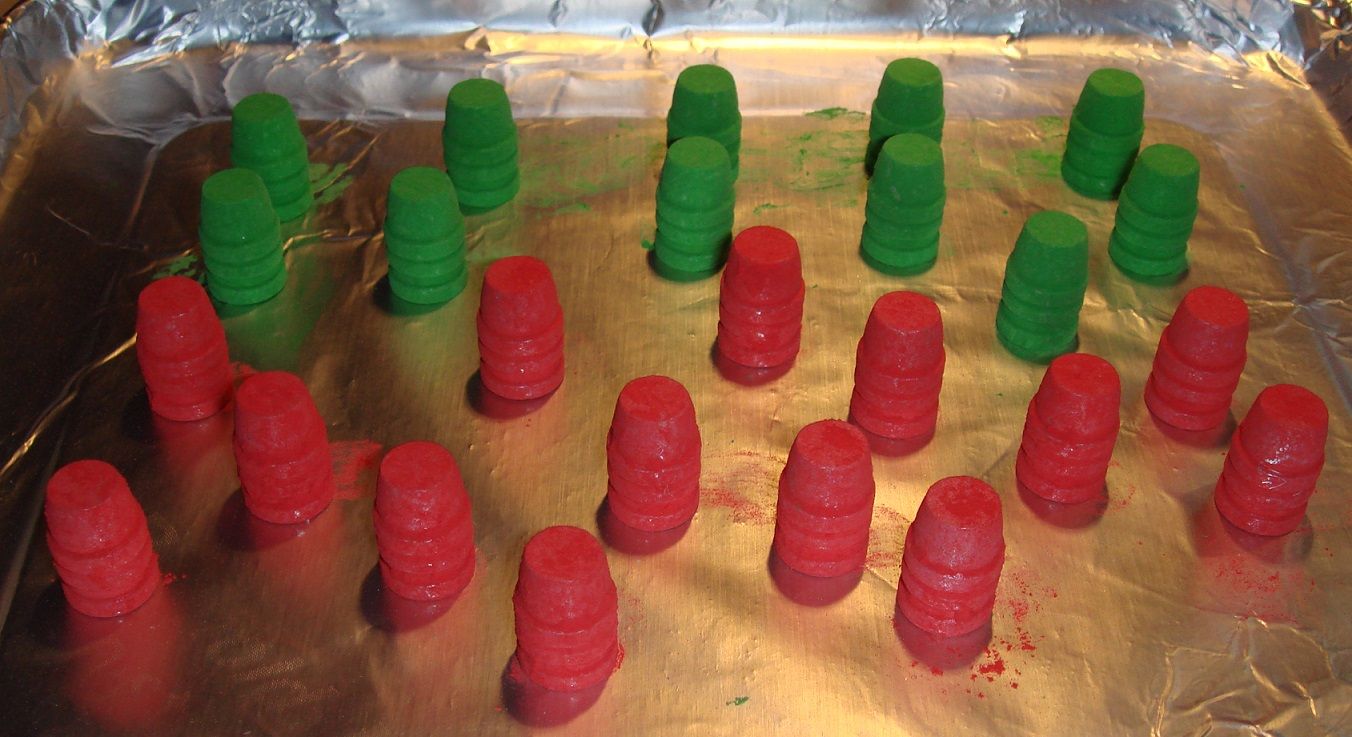

Kinda powdery, ready to bake. Maybe a little too powdery, but at least fully coated. I coulda tapped em once and it wouldn't have hurt anything.

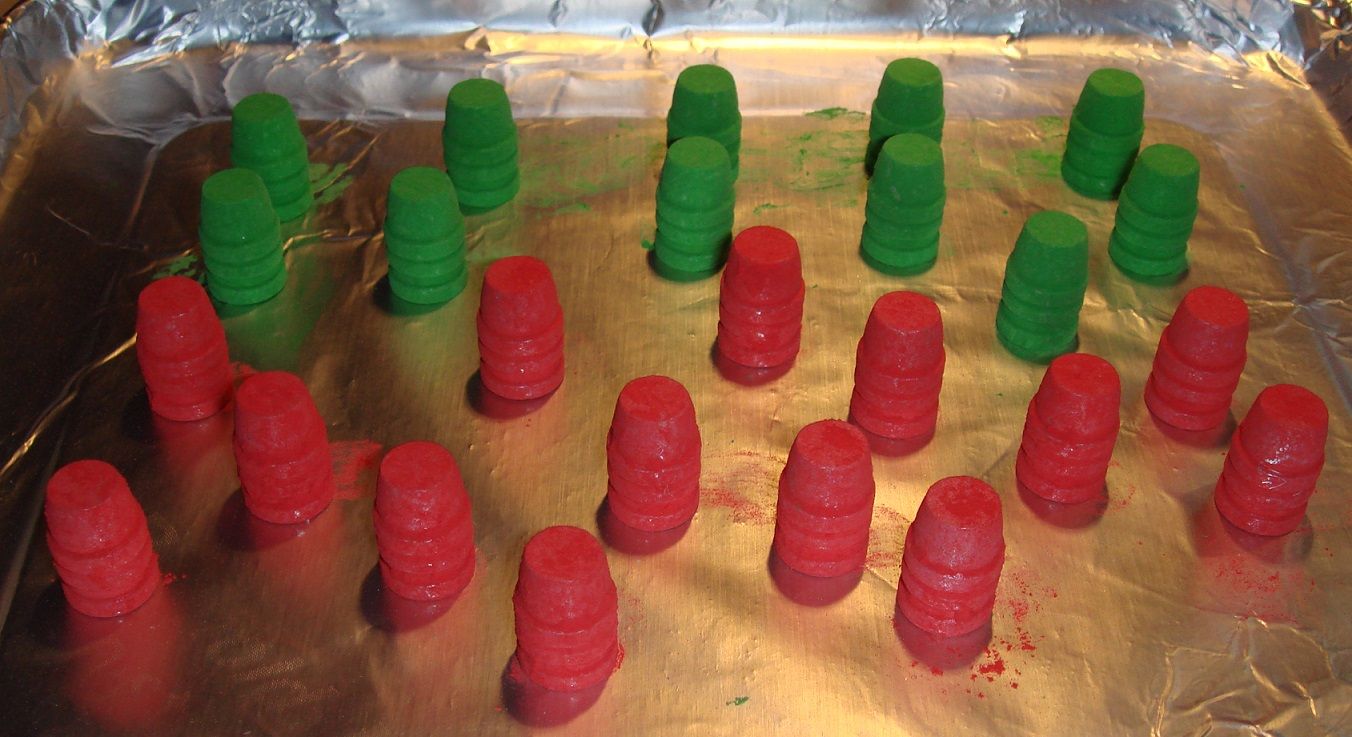

Fresh as cookies outta the oven. Now off to the sizer...

My results with latex gloves.....

Some guys have been getting really pretty results from using the ASBBs in Ziplock bags and shaking/massaging it around and then picking the bullets out with latex gloves, and even smoothing the coating a little bit by gently spinning the bullets on the paper/foil with their gloved powdery fingers. I had tried it once before using plastic tubs and nitrile gloves and it didn't work well, but I wanted to give this a whirl.

Got some latex gloves. Dumped powder and ASBBs in ziplocks and massaged well. Bullets only took on lightly colored sheen of red or green. (I tried both colors) A lot of silver was still showing. And the gloves only rubbed more off of them, even though I dipped fingers in powder first.

So I dumped all into the CoolWhip bowls and shook good. Then tried lifting out carefully with gloves and smoothing out the bullets while they were standing on the foil. I spun them gently and tried to get a good coat. It just made it spotty. It worked exactly the way my earlier test with nitrile gloves did.

So I dumped em back and tumbled good again and picked out of CoolWhip bowl with sharpened pliers and sat on foil gently. Got good coat again.

Apparently, here with my humidity, in my static level of my work area, the pliers and CoolWhip bowl are still the best/fastest way to get a good shootable coat.

Kinda powdery, ready to bake. Maybe a little too powdery, but at least fully coated. I coulda tapped em once and it wouldn't have hurt anything.

Fresh as cookies outta the oven. Now off to the sizer...

Last edited: