You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Receiver Opinions Please

- Thread starter CowTowner

- Start date

tarheelpwr

New member

Hi - Thanks for all all the input. Would those actions be appropriate for a 404 Jeff build? Or, would I be money ahead to just start out with a CZ 500 mag action from Brownells and take the easy way out?

I have no tooling or machines, so I'd be paying for any mods that needed done to the action. What all would they be?

Open up bolt face

Adjust feed ramps

?

I have no tooling or machines, so I'd be paying for any mods that needed done to the action. What all would they be?

Open up bolt face

Adjust feed ramps

?

tarheelpwr, were I in your shoes, I'd print the web page displaying the receiver and take it to my local smithy.

Ask him/her to look at it and give you a professional opinion. That way you can also get a ballpark quote for the cost of the work involved to modify to your desires.

Ask him/her to look at it and give you a professional opinion. That way you can also get a ballpark quote for the cost of the work involved to modify to your desires.

FrankenMauser

New member

tarheel, it is my (amateur) opinion that you'd be better off starting with a magnum-length action.

With a ".375 H&H" CZ receiver....

The bolt face should already be over 0.500" (less metal to remove and less time spent on the extractor).

The COAL of .404 Jeffery won't be an issue.

The feed ramps are likely to require less (if any) work.

And the magazine feed lips / guide rails should require less work (if any).

The ".416 Rigby" CZ receiver would actually require the bolt face to be bushed smaller, and the extractor would need to have metal added or be replaced entirely. But, I believe that it would, otherwise, require less modification for .404 Jeffery than the ".375" receiver.

There's really no guarantee of anything, with any receiver, though. Each piece of metal is its own world. They're all unique.

With a ".375 H&H" CZ receiver....

The bolt face should already be over 0.500" (less metal to remove and less time spent on the extractor).

The COAL of .404 Jeffery won't be an issue.

The feed ramps are likely to require less (if any) work.

And the magazine feed lips / guide rails should require less work (if any).

The ".416 Rigby" CZ receiver would actually require the bolt face to be bushed smaller, and the extractor would need to have metal added or be replaced entirely. But, I believe that it would, otherwise, require less modification for .404 Jeffery than the ".375" receiver.

There's really no guarantee of anything, with any receiver, though. Each piece of metal is its own world. They're all unique.

FrankenMauser

New member

I took a two "small jobs" to my preferred gunsmith last weekend, and it turned out to be a combination that really grabbed his attention (.475 Tremor needing a muzzle brake pinned, and the Dumoulin action). So, his backlog of 6-8 weeks worked out to a turnaround time of 4 days, for me. ...Because he kept fondling them with intrigue, every time he picked them up off of the bench to put them in the safe. But, they never made it. On Monday, he went right to work, instead.

When he called me Wednesday, I asked him to chop the Dumoulin's barrel, even if I had to wait several weeks. That took another day. So, I picked everything back up today.

The barrel, as it turned out, had threads that were 55 degree Whitworth, but 0.009" oversized. He turned the diameter down, chased the threads, and it threaded into the receiver like butter.

I don't think I've mentioned it before, but this barrel is one of the Sarco "Belgian" .270 Win barrels that they had for $75 or $100. I was a little leery of the price and claims, but the bore looked fantastic and slugged perfectly when it arrived. So, I'm giving it a shot.

And that puts me at:

Stock inletting.

I have everything that I need for this build.

What I don't have are some options:

1. Butt pad. As is, I could make a butt plate from the brass that I used for my .444 Marlin project. But, I'd rather not. It doesn't fit the style of the build.

2. Express sights. I really want express sights, but they don't fit with the intended use of this rifle (even though they do fit the style). So, I'm hoping I can find another project to obsess about, in regards to the 'express' concept.

3. Grip cap and/or fore-end tip. I don't think this stock will look right without a contrasting fore-end tip, and a grip cap will round out the look. But the wood that I ordered isn't what I expected, and just isn't right for the job. So, I'm trying to find something that I can use on more than just this Maple stock, in order to create my own 'signature look' for the grip cap and tip. It's something my grandfather always used to do (with dark, marbled rosewood and an inlaid white diamond). I want to keep with the tradition, but I want this to be mine ... and a little more modern.

I know you want some gunporn, so I'll post a photo next chance I get when there's natural light available. ...But it probably won't be this weekend.

When he called me Wednesday, I asked him to chop the Dumoulin's barrel, even if I had to wait several weeks. That took another day. So, I picked everything back up today.

The barrel, as it turned out, had threads that were 55 degree Whitworth, but 0.009" oversized. He turned the diameter down, chased the threads, and it threaded into the receiver like butter.

I don't think I've mentioned it before, but this barrel is one of the Sarco "Belgian" .270 Win barrels that they had for $75 or $100. I was a little leery of the price and claims, but the bore looked fantastic and slugged perfectly when it arrived. So, I'm giving it a shot.

And that puts me at:

Stock inletting.

I have everything that I need for this build.

What I don't have are some options:

1. Butt pad. As is, I could make a butt plate from the brass that I used for my .444 Marlin project. But, I'd rather not. It doesn't fit the style of the build.

2. Express sights. I really want express sights, but they don't fit with the intended use of this rifle (even though they do fit the style). So, I'm hoping I can find another project to obsess about, in regards to the 'express' concept.

3. Grip cap and/or fore-end tip. I don't think this stock will look right without a contrasting fore-end tip, and a grip cap will round out the look. But the wood that I ordered isn't what I expected, and just isn't right for the job. So, I'm trying to find something that I can use on more than just this Maple stock, in order to create my own 'signature look' for the grip cap and tip. It's something my grandfather always used to do (with dark, marbled rosewood and an inlaid white diamond). I want to keep with the tradition, but I want this to be mine ... and a little more modern.

I know you want some gunporn, so I'll post a photo next chance I get when there's natural light available. ...But it probably won't be this weekend.

FrankenMauser

New member

I'm not much of a fan of Cherry. Plus, most Cherry woods are fairly soft, which isn't what you want for a tip or grip cap. (650-900 Janka hardness, versus 1,150-1,600 for Walnut and Maple varieties suitable for stock making.)

I'll figure it out eventually.

I'll figure it out eventually.

Dixie Gunsmithing

Moderator Emeritus

FrankenMauser, Take a look at Rosewood. They make chunks big enough, and I think you can get them from Woodcraft. They have other exotic woods, and some are pretty tough.

http://www.woodcraft.com/category/SU114-22-01/hardwood-turning-stock.aspx

http://www.woodcraft.com/category/SU114-22-01/hardwood-turning-stock.aspx

FrankenMauser

New member

I appreciate the help, but I generally don't like Rosewood, either.

Right now, I'm trying to track down some Coolibah in a size that's useful to me (most places only have pen blanks), and from a seller that will let me pick the specific piece that I want.

I'm considering many other things, as well; but Jobillo and Jicarillo are close to the top of the list right now.

Right now, I'm trying to track down some Coolibah in a size that's useful to me (most places only have pen blanks), and from a seller that will let me pick the specific piece that I want.

I'm considering many other things, as well; but Jobillo and Jicarillo are close to the top of the list right now.

Just another thought to throw at the fan

http://shop.arizonaironwood.com/

http://shop.arizonaironwood.com/

FrankenMauser

New member

Thanks for the link.

little pocket of sap on the fore-end. Since I actually like a few defects,

Personally, I find some sapwood can add character as long as it's not in a "wrong" (structural) location like the wrist or recoil lug area. End of the barrel certainly isn't an issue- nice looking piece of wood.

It'll be really nice to be working with a "soft" wood.

LOL....guess it is all relative. I'll still take Maple over the birch laminates...cut just a few stocks and the bits are off to be sharpened. Damned glue...

Butt pad. As is, I could make a butt plate from the brass that I used for my .444 Marlin project. But, I'd rather not. It doesn't fit the style of the build.

You don't want to fit a commercial pad like a Limbsaver or Pachmayr to it?

FrankenMauser

New member

I plan to. I just don't have one yet.You don't want to fit a commercial pad like a Limbsaver or Pachmayr to it?

I need to figure out what I'm doing for the grip cap and fore-end tip. That will decide the color for the recoil pad.

I simply phrased the statement the way that I did, because I don't consider a recoil pad / butt pad to be a necessity with .270 Win. Rather, it's an optional extra - an upgrade from a solid butt plate.

I have some birdseye maple, marblewood, snakewood, and something else (black palm as an accent?) coming from suppliers that let me choose the specific pieces that I wanted. We'll see if the pieces look good enough in person to tweak my gigglers, and where that takes me.

It may all be a moot point, at the moment, though. The humidity has spiked in my basement, again (which usually lasts all summer). And, last night, I noticed minor, but definite, swelling in the screwbean mesquite stock that I've been shaping lately.

If I can't get the humidity under control, the moisture content of the wood could theoretically increase to 9.2% by the end of summer. ...And that's nearly double what I want when I seal the wood; since my firearms spend most of their time in very dry environments - at just 10-30% RH.

Right now, I have all of my hygrometers scattered around the house and garage, hoping to find a place that's more stable at no more than 36% relative humidity.

FrankenMauser

New member

I think I have a winner.

Marblewood. - One or two of the pieces that I ordered, anyway. The other wood will be used for something else.

(The inlay is still up in the air - if I even do it.)

Dampened with mineral spirits, and overly-yellow in the photo:

(Sorry about the aggressive cropping. I had to get the file size down.)

Dry, with the stock:

Marblewood. - One or two of the pieces that I ordered, anyway. The other wood will be used for something else.

(The inlay is still up in the air - if I even do it.)

Dampened with mineral spirits, and overly-yellow in the photo:

(Sorry about the aggressive cropping. I had to get the file size down.)

Dry, with the stock:

Attachments

Dixie Gunsmithing

Moderator Emeritus

FrankenMauser. That would make some nice looking pistol grips, too.

FrankenMauser

New member

Indeed. I plan to let as little as possible go to waste.

I am working on a Dumoulin Mauser with #3 taper Shilen select mach stainless 4 ratchet riflings in 8" twist with Boyd's pro varmint stock with a chunk of Aluminum in it for a recoil lug / front pillar / bi pod and sling mount.

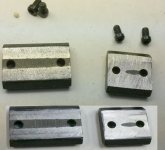

I took the flat bottom modified Weaver S46 and S54 scope bases off and scored the receiver so adhesive can get a better grip.

I broke the sharp edges to make it more ergonomic. I went after the back of the safety shroud, the safety lever, the receiver, and the ejector box. That also removed some bluing. I used a soft abrasive wheel in an arbor I made from a 5/8-11 bolt and put it in the mini lathe.

https://www.use-enco.com/CGI/INSRIT?PMAKA=MK317-1741

same as below

I took the flat bottom modified Weaver S46 and S54 scope bases off and scored the receiver so adhesive can get a better grip.

I broke the sharp edges to make it more ergonomic. I went after the back of the safety shroud, the safety lever, the receiver, and the ejector box. That also removed some bluing. I used a soft abrasive wheel in an arbor I made from a 5/8-11 bolt and put it in the mini lathe.

https://www.use-enco.com/CGI/INSRIT?PMAKA=MK317-1741

same as below

Attachments

Last edited:

Here is a pic of the bottom of the modified scope bases.

Here is some calculations I did on scope bases.

Scope base screws are not stressed in shear, but in tension.

If my 142 gr bullet [Nosler accubond long range with 54 gr H4350 per Quickload] maximum acceleration is from 500 fps to 2000 fps in 0.4 ms then an 8 pound rifle will try to accelerate from 1.27 fps to 5.07 fps in 0.4 ms. This is an acceleration of 9500 ft/sec squared.

If a 2 pound scope were part of that 8 pound rifle during that acceleration the force between the rifle and the scope would be

f = m a = 2 pounds 9500 f/ss = [9500 f/ss] [2 pounds / [Gc = 32 f/ss]]= 594 pounds.

If there were 4 screws in shear that would be 148 pounds force / screw.

That screw has a 0.12" minor diameter

A = pi r r = .011 sq in

Grade 5 bolt [American cap screws] has a shear strength of 72,000 psi

Each screw would have a shear strength of 814 pounds.

But they are not in shear.

They are in tension.

Grade 5 bolts are good for 127,000 psi in tension.

Each screw is good for 1436 pounds force in tension.

They are pre loaded to about half that, making a clamping force of 700 pounds.

The coefficient of static friction between the steel scope base and the receiver is ~ 0.6

So each screw provides a static state up to 420 pounds recoil force.

4 screws 1680 pounds.

But the hard kicking lightweight rifle and heavy scope only have 594 pounds peak force between them.

1680 pounds friction is greater than 420 pounds recoil, therefor the bases stay put.

I think I learned something. I have long been puzzled. With my hundreds of beater rifles and those I help at the range, half the time the problem with poor groups is loose base screws. Never the ring caps or cross bolts. Why do just the base screws get loose?

https://en.wikipedia.org/wiki/Friction

Scroll down to steel on steel coefficient of static friction.

Clean and dry: 0.76 - 0.80

Lubricated: 0.16

0.16?

That would case the scope to come loose.

Who would put oil on a gun?

link same as pic above

Attachments

Last edited:

To increase the static friction between the flat topped Dumoulin bridges and the #S46 and #S54 Weaver bases modified to be flat bottomed, I have put Loctite 242 between them.

To keep that bases aligned until the Loctite is hard, I have modified an AR 15 riser to use as a fixturing device.

http://www.amazon.com/UTG-1-Inch-13-slot-Hi-profile-Riser/dp/B003TWX8HS

To keep that bases aligned until the Loctite is hard, I have modified an AR 15 riser to use as a fixturing device.

http://www.amazon.com/UTG-1-Inch-13-slot-Hi-profile-Riser/dp/B003TWX8HS