You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Receiver Opinions Please

- Thread starter CowTowner

- Start date

FrankenMauser

New member

I believe they are 1/4"-20 (or close metric equivalent), which would be ~65 in-lb.

I, personally, would torque the front screw to 65-80 in-lb and the rear to 30-45 in-lb. ...Just personal preference, but the tang can be bent by over-torquing the rear screw if the pillar is not the correct length.

I, personally, would torque the front screw to 65-80 in-lb and the rear to 30-45 in-lb. ...Just personal preference, but the tang can be bent by over-torquing the rear screw if the pillar is not the correct length.

They are 1/4-22 with 5 turns of engagement.

The root, minor diameter is ~0.19"

1.2 times the root is .228"

The pitch is 1"/22=.045"

5 times the pitch is .227" of engagement.

So at failure the screw will snap rather than the female strip, barely.

http://www.portlandbolt.com/technical/bolt-torque-chart/

For the weakest [A307] 1/4-20 screw waxed the recommended torque is 24 in lb

For the weakest 1/4-20 screw lubed with oil or grease the recommended torque is 36 in lb

For the weakest 1/4-20 screw dry the recommended torque is 48 in lb

.

.

For the strongest [grade 8] 1/4-20 screw dry the recommended torque is 144 in lb.

I would do ~~ what FrankenMauser said and buy another pair for $6 if they ever snap off

http://www.midwayusa.com/product/28...-screws-mauser-96-98-non-locking-package-of-2

The root, minor diameter is ~0.19"

1.2 times the root is .228"

The pitch is 1"/22=.045"

5 times the pitch is .227" of engagement.

So at failure the screw will snap rather than the female strip, barely.

http://www.portlandbolt.com/technical/bolt-torque-chart/

For the weakest [A307] 1/4-20 screw waxed the recommended torque is 24 in lb

For the weakest 1/4-20 screw lubed with oil or grease the recommended torque is 36 in lb

For the weakest 1/4-20 screw dry the recommended torque is 48 in lb

.

.

For the strongest [grade 8] 1/4-20 screw dry the recommended torque is 144 in lb.

I would do ~~ what FrankenMauser said and buy another pair for $6 if they ever snap off

http://www.midwayusa.com/product/28...-screws-mauser-96-98-non-locking-package-of-2

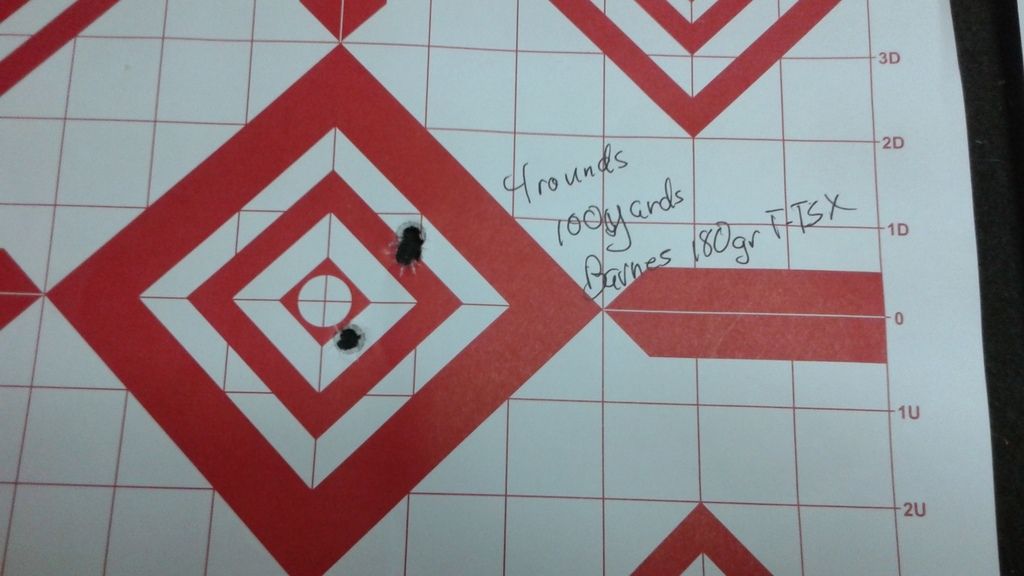

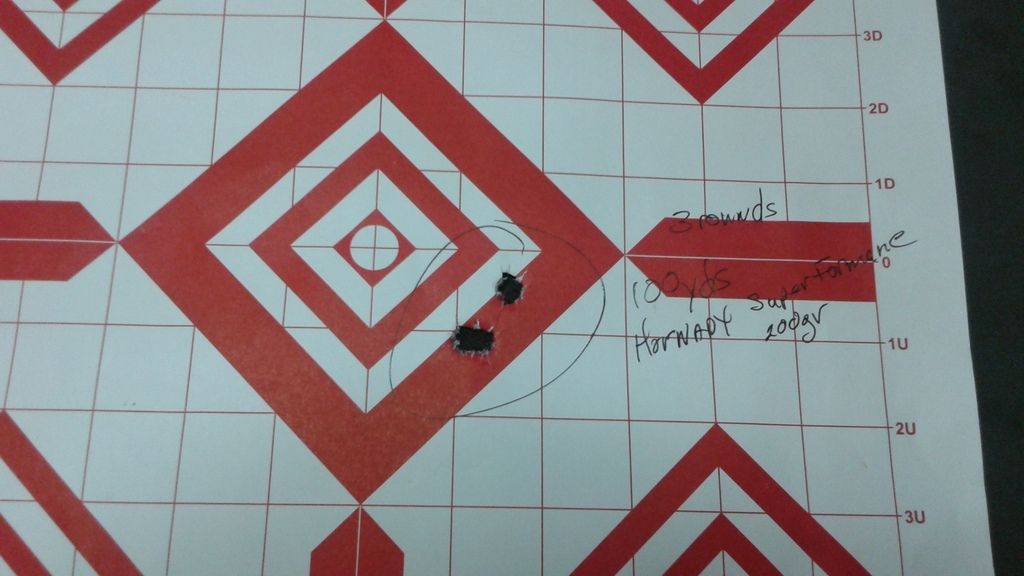

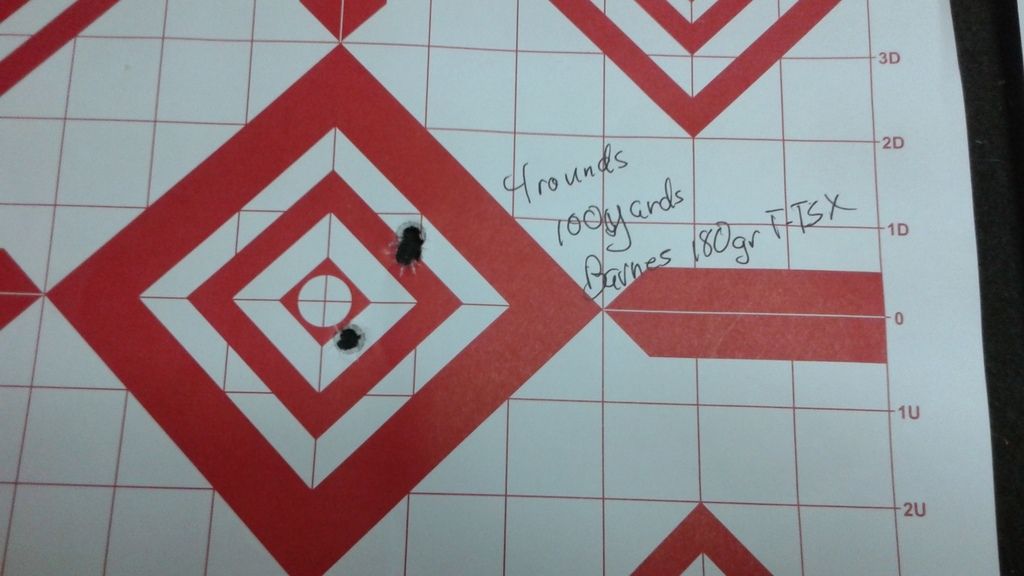

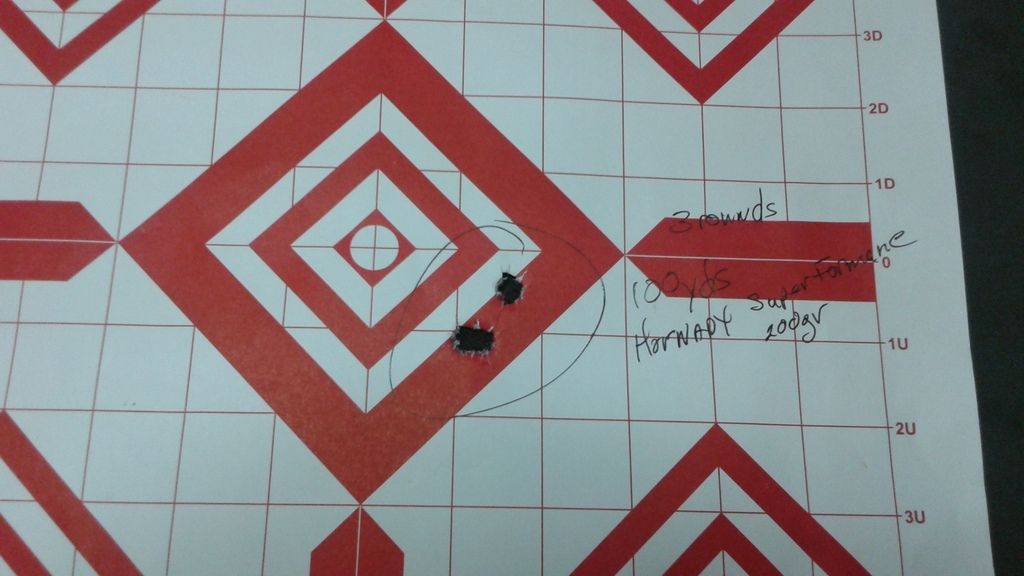

Well, no accounting for my rifle skills as a marksman. It appears the new toy likes them fast (2900+ fps). The slower loads didn't come close to grouping as well as these. The others were Remington Core-Lokt 200 grain (THE most expensive of the 4 tested) and Federal Fusion 200 grain.

Yes, that was 4 rounds and all 4 hit the target. Don't ask me how I did it though.

I think the build can be considered a success! Now I gotta figure out how to get my handloads to perform like the factory loads. On to the loading bench!

Yes, that was 4 rounds and all 4 hit the target. Don't ask me how I did it though.

I think the build can be considered a success! Now I gotta figure out how to get my handloads to perform like the factory loads. On to the loading bench!

FrankenMauser

New member

Congrats on the finished rifle (I must have missed your post last month).

It looks like the barrel has some potential.

Mine is still on the back burner. I have a couple higher priorities that need my attention right now. Plus... I still haven't taken the barrel in to get the threads fixed, or done so much as look around for a stock (other than the casual glace at the local gun shops).

I can't work on anything right now, anyway. The warm weather makes the humidity in my basement skyrocket. Anything I touch instantly rusts.

It looks like the barrel has some potential.

Mine is still on the back burner. I have a couple higher priorities that need my attention right now. Plus... I still haven't taken the barrel in to get the threads fixed, or done so much as look around for a stock (other than the casual glace at the local gun shops).

I can't work on anything right now, anyway. The warm weather makes the humidity in my basement skyrocket. Anything I touch instantly rusts.

Last edited:

Cowtowner,

Thanks.

I went to that site, and it got expensive with the stock you chose and all the options.

I ordered (5) pro varmint stocks:

1903 Turkish Mauser

98 Mauser

Rem 700 long

Mosin Nagant

Sav 110 long

I already have a pro varmint [tacticool name went away] in Sav 110 short.

i have a plan to make heavy generic test stock for the Dumoulin receivers when I barrel them. After I shoot a small group with a 40X scope and a heavy stock, there will not be as many possible excuses when the dog does not hunt.

Thanks.

I went to that site, and it got expensive with the stock you chose and all the options.

I ordered (5) pro varmint stocks:

1903 Turkish Mauser

98 Mauser

Rem 700 long

Mosin Nagant

Sav 110 long

I already have a pro varmint [tacticool name went away] in Sav 110 short.

i have a plan to make heavy generic test stock for the Dumoulin receivers when I barrel them. After I shoot a small group with a 40X scope and a heavy stock, there will not be as many possible excuses when the dog does not hunt.

I did neglect to include that the stock is a Prairie Hunter model. I went with the higher comb due to the medium rings used so the bolt handle was clear of the scope.

Now I see they are offering adjustable combs. Wish they had those when I replaced my sporterized No.4 Mk.1 stock.

Now I see they are offering adjustable combs. Wish they had those when I replaced my sporterized No.4 Mk.1 stock.

FrankenMauser

New member

After seeing the updates here, I spent some time (a lot of time) digging around and ended up ordering a stock last night.

Just a basic piece of Maple with a 98 large ring inlet. I am not a huge fan of the style - high comb English Express - but the price that I paid was ridiculous (low, way low) because there is a little pocket of sap on the fore-end. Since I actually like a few defects, here and there, it's a win-win.

I figure there should be enough wood left on the 'express' side panels for me to do a little reshaping for more of an American look with a shadow-line cheek piece. If not... I'll dress them appropriately and just roll with it.

I really wanted to go for a Mannlicher-style build (and came across some fantastic black walnut stocks), but I had to bite the bullet and admit that I just don't have the skill for it, yet. Maybe on the next build.

Regardless... It'll be really nice to be working with a "soft" wood. I've been working with Knotty Screwbean Mesquite for the last year, and it's a beast. Hard. Unpredictable. Hard. Porous. Did I mention, hard? (Notably harder than even ebony.)

Terrible picture, but it's all I have to share for now:

Now, I really need to get this barrel off to a 'smith to get the threads fixed. That's the only thing holding me back, besides humidity.

Just a basic piece of Maple with a 98 large ring inlet. I am not a huge fan of the style - high comb English Express - but the price that I paid was ridiculous (low, way low) because there is a little pocket of sap on the fore-end. Since I actually like a few defects, here and there, it's a win-win.

I figure there should be enough wood left on the 'express' side panels for me to do a little reshaping for more of an American look with a shadow-line cheek piece. If not... I'll dress them appropriately and just roll with it.

I really wanted to go for a Mannlicher-style build (and came across some fantastic black walnut stocks), but I had to bite the bullet and admit that I just don't have the skill for it, yet. Maybe on the next build.

Regardless... It'll be really nice to be working with a "soft" wood. I've been working with Knotty Screwbean Mesquite for the last year, and it's a beast. Hard. Unpredictable. Hard. Porous. Did I mention, hard? (Notably harder than even ebony.)

Terrible picture, but it's all I have to share for now:

Now, I really need to get this barrel off to a 'smith to get the threads fixed. That's the only thing holding me back, besides humidity.

Attachments

FrankenMauser,

I built a 300 pound "modern work bench" per the Lee Valley plans from Rockhard Maple.

I chopped all the mortice joints with Stanley paring chisels.

That was 31 years ago, and my hands STILL hurt.

Attachments

FrankenMauser

New member

I can definitely identify with that right now.

My hands are beaten, battered, raw, aching, and swollen like footballs.

I bought a "junk" car yesterday and had to spend about 4 hours swapping a 1100+ CCA battery between my crappy van (for charging) and the junk car -- using the starter and manual transmission to park the non-running car where I needed it.

And then, when I went to see if the only key I have for the car actually matched the door locks, the tumbler locked up solid and wouldn't release the stupid thing.

Disassembling and reassembling that door required a lot more 'aggression' than anticipated, and my hands aren't happy about it.

No work in the gun room today...

My hands are beaten, battered, raw, aching, and swollen like footballs.

I bought a "junk" car yesterday and had to spend about 4 hours swapping a 1100+ CCA battery between my crappy van (for charging) and the junk car -- using the starter and manual transmission to park the non-running car where I needed it.

And then, when I went to see if the only key I have for the car actually matched the door locks, the tumbler locked up solid and wouldn't release the stupid thing.

Disassembling and reassembling that door required a lot more 'aggression' than anticipated, and my hands aren't happy about it.

No work in the gun room today...

I have found some sharp edges on the Dumoulin Mauser receiver and have got a plan for how to fix them.

Afterwards I will put some of the original Herter's Belgian Blue formula.

That is my plan. What could go wrong?

Afterwards I will put some of the original Herter's Belgian Blue formula.

That is my plan. What could go wrong?

Attachments

FrankenMauser

New member

Just don't let it get away from you and end up being a Mauser with the "carry melt" look.

I buy generic "Cratex" wheels (tired of paying for the name) for the Dremel in quantity from a supplier on Ebay, they work great for small or "tight" areas. Takes off sharp edges, melds grinding marks (and like FrankenMauser said, will give you the "melt" look if you're not careful).

I was surprised at the large selection of both the compound they can be made from- as well as the grit size. I didn't know they're widely used by dentists...

I was surprised at the large selection of both the compound they can be made from- as well as the grit size. I didn't know they're widely used by dentists...

Dixie Gunsmithing

Moderator Emeritus

The generic Cratex seems to be just as good, if not better. The experience I've had with the Cratex brand, is that they wear away very quickly. For the cost, and the quick wear, I imagine Cratex makes a fortune.

I've bought a lot of this stuff from eBay, as much is listed by jeweler suppliers. For a Gunsmith, one ought to look over the Jeweler's tools, as they can be used for Gunsmithing, and some are not stocked by Brownell's.

I've bought a lot of this stuff from eBay, as much is listed by jeweler suppliers. For a Gunsmith, one ought to look over the Jeweler's tools, as they can be used for Gunsmithing, and some are not stocked by Brownell's.