Stagpanther,

There is a reflected gas pressure wave phenomenon that can occur and that has been known to damage artillery pieces, but rifles are too short for it to occur in. There is a pressure (longitudinal) wave created in the barrel steel when a bullet hits the throat and the chamber starts to expand a little more, but that travels in the steel at around 17 times the speed of sound, so you see its ripples in the pressure trace. There is probably a much slower transverse surface wave associated with that, but I don't think it has much effect on readings. I'm not sure what Jim was referring to.

Yes, the actual pressure is locally much higher at the point of pressure. As I've mentioned in other threads, Texas gunsmith Charlie Sisk has actually blown muzzles off 338's with them. Took him nine or ten shots of a particularly severe one of these loads to do it, but he could do it on demand; totally repeatable. But the photos I saw showed the breech end remaining intact.

Savvy Jack,

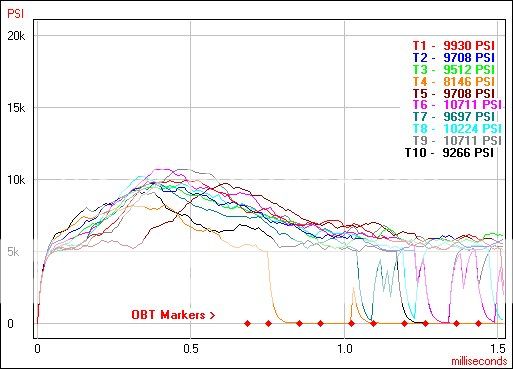

Congratulations on getting the unit to work for you. I'll point out you can improve on the graphics resolution. From the 80K at the top of the left side of the graph, I can see you had it in rifle sensitivity mode. Set it for handgun sensitivity and you will see a shorter scale and see the trace more clearly.

Just to give credit where it's due, I'll point out it is actually the hardware in the yellow box that does the measuring. The companion program just downloads the data from the instrument's memory and puts it into files you can store and review or manipulate. Pretty cool system.

There is a reflected gas pressure wave phenomenon that can occur and that has been known to damage artillery pieces, but rifles are too short for it to occur in. There is a pressure (longitudinal) wave created in the barrel steel when a bullet hits the throat and the chamber starts to expand a little more, but that travels in the steel at around 17 times the speed of sound, so you see its ripples in the pressure trace. There is probably a much slower transverse surface wave associated with that, but I don't think it has much effect on readings. I'm not sure what Jim was referring to.

Yes, the actual pressure is locally much higher at the point of pressure. As I've mentioned in other threads, Texas gunsmith Charlie Sisk has actually blown muzzles off 338's with them. Took him nine or ten shots of a particularly severe one of these loads to do it, but he could do it on demand; totally repeatable. But the photos I saw showed the breech end remaining intact.

Savvy Jack,

Congratulations on getting the unit to work for you. I'll point out you can improve on the graphics resolution. From the 80K at the top of the left side of the graph, I can see you had it in rifle sensitivity mode. Set it for handgun sensitivity and you will see a shorter scale and see the trace more clearly.

Just to give credit where it's due, I'll point out it is actually the hardware in the yellow box that does the measuring. The companion program just downloads the data from the instrument's memory and puts it into files you can store and review or manipulate. Pretty cool system.