I knew nothing about gunpowder lifetime until I ran into an Insensitive Munitions expert. This IM expert explained that powder deteriorates from the day it leaves the factory.

Nitrocellulose decomposes through the reduction-oxidation process. Called Redox. The expert said “The molecular stability of the functional groups on the organic chain determine the life time of the nitrocellulose molecule.” All ionic compounds, water is the main offender because it is always in air, react with those bonds and accelerates the deterioration of the powder.

The bottom line is that nitrocellulose is a high energy molecule that wants to become a low energy molecule.

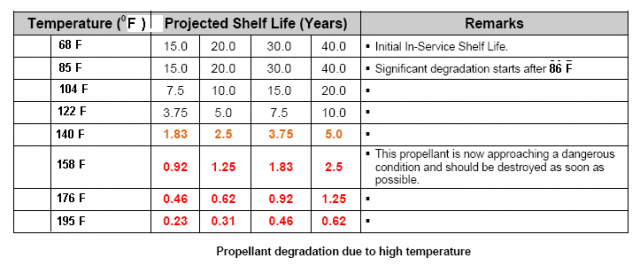

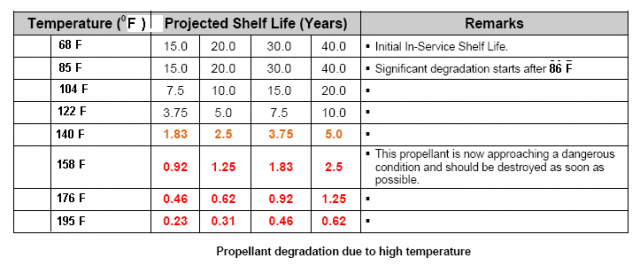

Heat accelerates the deterioration/decomposition of powder and the rate is directly proportional to the Arrhenius equation. If you read in the Insensitive munitions literature, you will see that they use high temperature to accelerate aging of smokeless propellants.

ROLE OF DIPHENYLAMINE AS A STABILIZER IN PROPELLANTS;

ANALYTICAL CHEMISTRY OF DIPHENYLAMINE IN PROPELLANTS

Nitrocellulose-base propellants are essentially unstable materials

that decompose on aging with the evolution of oxides of nitrogen. The

decomposition is autocatalytic and can lead to failure of the ammunition or disastrous explosions.

http://www.dtic.mil/dtic/tr/fulltext/u2/783499.pdf

Heat, as you can see in the report, will age gunpowder

Combustion pressures will rise after high temperature storage.

INVESTIGATION OF THE BALLISTIC AND CHEMICAL STABILITY OF 7.62MM AMMUNITION LOADED WITH BALL AND IMR PROPELLANT

Frankfort Arsenal 1962

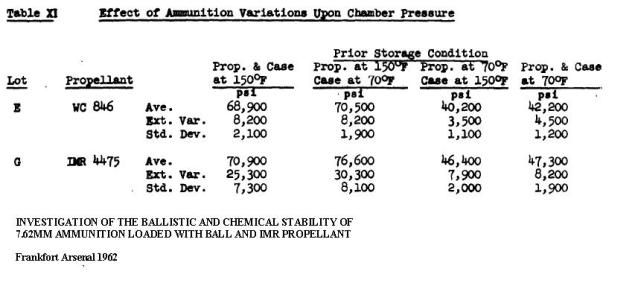

3. Effects of Accelerated Storage Propellant and Primer Performance

To determine the effect of accelerated isothermal storage upon propellant and primer performance, sixty cartridges from each of lots E (WC 846) and G (R 1475) were removed from 150F storage after 26 and 42 weeks, respectively. The bullets were then removed from half the cartridges of each lot and from an equal number of each lot previously stored at 70F. The propellants were then interchanged, the bullets re-inserted, and the cases recrimped. Thus, four variations of stored components were obtained with each lot.

Chamber pressures yielded by ammunition incorporating these four variations were as follows. These values represent averages of 20 firings.

UN manual on ammunition inspection. See section 7.3.

Surveillance and in-service proof - the United Nations

http://www.un.org/disarmament/conva...20-Surveillance_and_In-Service Proof(V.1).pdf

Double based powders have a reduced lifetime compared with single base. Double based powders have nitroglycerin (NG) in the grain. Nitroglycerine remains a liquid and it migrates within the grain to react with the NO bonds on the nitrocellulose, increasing the rate of reduction-oxidation reaction. All ionic compounds react with those bonds and accelerate the deterioration of the powder. Rust is bad as ferric oxide is ionic. Water is polar covalent ion and it reacts with the double bonds.

Because water reacts in a negative way with smokeless propellants, quality ammunition is manufactured in humidity controlled environments. Between 40% and 20% humidity. They don't go lower due to electro static discharge concerns.

The best storage condition for powders is arctic. Cold and dry.

Due to the migration of NG within double based powders, the surface of the grain will become rich in NG even though the total energy content of the propellant has decreased. This will cause changes in the burn rate, and can cause pressures to spike. The surface of nitrocellulose powders also change as the powder deteriorates, and it changes unevenly. This creates conditions for erratic burn rates. Burn rate instability is undesirable and can cause explosive conditions in firearms. In retrospect, this explains the “funny” retorts I experienced and the sticking cases. It is an extremely rare occurrence, but old ammunition has caused rifle Kabooms. When I discussed this with a machine gunner buddy, he said that explained the two top cover explosions he had with old Yugoslavian 8 MM ammo. I think it explains the Garand kaboom in the link below.

Section from the Propellant Management Guide:

Stabilizers are chemical ingredients added to propellant at time of manufacture to

decrease the rate of propellant degradation and reduce the probability of auto ignition during its expected useful life.

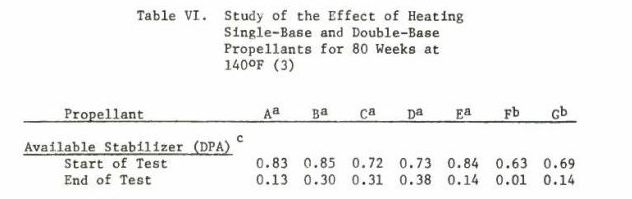

As nitrocellulose-based propellants decompose, they release nitrogen oxides. If the nitrogen oxides are left free to react in the propellant, they can react with the nitrate ester, causing further decomposition and additional release of nitrogen oxides. The reaction between the nitrate ester and the nitrogen oxides is exothermic (i.e., the reaction produces heat). Heat increases the rate of propellant decomposition. More importantly, the exothermic nature of the reaction creates a problem if sufficient heat is generated to initiate combustion. Chemical additives, referred to as stabilizers, are added to propellant formulations to react with free nitrogen oxides to prevent their attack on the nitrate esters in the propellant. The stabilizers are scavengers that act rather like sponges, and once they become “saturated” they are no longer able to remove nitrogen oxides from the propellant. Self-heating of the propellant can occur unabated at the “saturation” point without the ameliorating effect of the stabilizer. Once begun, the self-heating may become sufficient to cause auto ignition.

NOx gas is a mix of compounds all of which are reactive.

http://en.wikipedia.org/wiki/NOx http://en.wikipedia.org/wiki/Nitrogen_oxide When smokeless propellants break down NOx gas is released. Nitric acid gas is only produced in the presence of water, because it requires a hydronimun ion, but there is plenty of water in air.

The Armed Forces have stockpile surveillance programs but each Service does theirs a little differently. If you want to see all the different tests the military uses to determine propellant characteristics, look at Mils Std 286 Propellants, Solid: Sampling, Examination and Testing to be found at

https://assist.daps.dla.mil/quicksearch/.

If you look, you will find aging tests. One common test is for powder to be kept at 65 C (150 F) until it fumes. It if fumes within 30 days it is checked for stabilizer or scrapped.

The Navy expert told me a few ways the Navy samples its powders and propellants. If the powder is outgassing nitric gas (as determined by change of color of methly violet paper in contact with the powder (Methly Violet test, or Talliani test)), the stuff is tested to see how much stabilizer is left. If the amount is less than or equal to 20%, the lot is scrapped.

Scrapping powders and propellants with this percentage of stabilizer appears to be consistent across all services.

Pages 5-11 of the 2003 Army Logistics Propellant Management Guide provide the protocols for testing and subsequent actions for their Stockpile Propellant Program. Basically, all propellant lots are tracked. The trigger for investigation is: "When Master Sample Stability Failure Occurs"

The Navy expert provided 'rules of thumb' concerning when to expect problems with double based and single based propellants. The rules of thumb are: Double based powders and ammunition are scrapped at 20 years, single based 45 years. In his words “

These 'rules of thumb' are particularly useful when the protocol fails. The protocol can easily fail when workmanship or good housekeeping measures are not followed during manufacture of propellant and/or rocket motor or during storage of the weapon system components, respectively.”

Early in the last century the storage lifetime of smokeless powders was considered to be 20 years or less:

Army Ordnance Magazine, June 1931, page 445 says:

“Smokeless powder constitutes one of the greatest hazards from a storage standpoint, due to the fact that it is subject to deterioration and at the best cannot be expected to have a life greater than about twenty years…….Master samples of all lots of smokeless powder are under constant observation in the laboratories at Picatinny Arsenal. Should any of these samples indicate rapid deterioration, notification is given at once, and steps are taken to use this deteriorating material within a very short period, if possible, or else withdraw it from service.”

For the home reloader, if the powder has turned red, or smells like acid, it is way beyond its safe limits. However, gunpowder and ammunition that has not obviously “bad” it becomes very hard to know the risk. I have, as all of us, shot ammunition from WW2, Korea, Vietnam era. I had pressure issues with Iraqi 303 ball, 8mm surplus, but I did not know at the time what was causing the pierced primers. I have shot 60’s vintage Bullseye, the stuff shot well and chronographed very consistently. But I have also shot surplus IMR 4895 that had no smell and that powder had pressure issues. CMP shooters report pressure problems with Greek ball in the 70’s.

I wish I could give a simple number for the lifetime of gunpowder, 10 years, 20 years, 30 years, but I can’t. There are too many variables, from the factory floor, to how the powder has been stored. This is what Federal says is the lifetime of their ammunition:

http://www.federalpremium.com/company/faq.aspx

What is the shelf life of ammo and storage?

Store reloading components and ammunition in a cool, dry place, protected from direct exposure to sunlight. If stored properly there is a 10-year shelf life on loaded ammunition.

But, for the curious, all you have to do is Google “Insensitive Munitions”, surplus ammunition Kabooms, and you will find much more than what I have put into this thread.

More to read if you wish:

www.dtic.mil/dticasd/sbir/sbir031/n154.doc

This paper discusses most of what I have written, but it has a confusing section where it states that “Suddenly, propellant that has spent its entire life in a configuration that was considered inherently safe from the risk of auto ignition is now bulk packaged and stored in a concentrated mass that may be sufficient to allow auto ignition to occur.” After discussions with the Navy expert I found that the insensitive munitions community has its own myths and legends. There are groups within the IM community who promote the “5 inch” rule. The theory is that for munitions 5 inch and smaller, the thermal mass of the case is sufficient to wick away heat and prevent auto ignition. The Navy expert considers this theory to be bogus and created by self serving individuals who get cash awards when they “extend the shelf life” of propellants. Never doubt the power of greed.

http://www.almc.army.mil/alog/issues/JulAug08/propellant_stab_eq.html

The pictures in this thread are just amazing, and evidence of powder that has deteriorated to the point that nitric acid gas is corroding the cases. And the reloader had pressure problems:

http://www.falfiles.com/forums/showthread.php?p=3745264

Has anyone else had Vihtavuori N140 corrode in loaded ammo?

I pulled two boxes (100 rounds total) of .308 ammo out of the safe I loaded about ten years ago and found some of them had blue powdery stuff coming out of the necks. I pulled a few rounds down and the inside case walls were powdery blue. The base of the bullets were corroded and blue. None of the other .308 ammo in the safe loaded with Varget has this problem. None of my pistol ammo looks to have anything wrong, but I haven't unloaded any of them. None of my blued guns have any rust. It's not a moist environment issue.

I've never had this happen before. Spent a lot of money loading this ammo for my AR-10 and used new brass, CCI BR2 primers, and N140 powder. It's all junk now.

What made me check it was I shot my AR-10 that's been sitting idle for about 8 years. Same ammo as what's in the boxes I checked. Out of the first ten rounds from the mag that was in the gun three blew primer pockets. I unloaded the rest of the cartridges and they were corroded.

I googled it and found one instance where someone else had the same thing happen

As for shooting WW2 era ammunition, take a look at this Garand Kaboom:

http://www.socnet.com/showthread.php?p=1344088

Another Garand Blowup with WWII ball

http://www.thehighroad.org/showpost.php?p=7870113&postcount=13

I have an old shooting buddy who some years ago was shooting some WWII ball (don’t know whose) but his M-1 was disassembled in a rather rapid fashion. He was lucky only his pride was hurt. He said he took a round apart and found rust looking dust along with the powder. Bad powder. Just sayin…..The op rod can be rebuilt which might be a good way to go. Op Rods are getting harder to find and when you find one a premium price is required so it seems. Garands require grease. I’m not sure if you are aware of this. If you are, please no offence taken.

http://www.usrifleteams.com/forums/index.php?showtopic=21886

Posted 17 July 2012 - 01:29 PM

'Tailgunner', on 17 Jul 2012 - 13:16, said:

I picked up some surplus ammo a couple of years ago and had a couple of hang fires. The hammer would drop and a second later the rifle would discharge.

After that happened a couple of times, I decided I wasn't going to shoot that stuff any more. So I took the ammo apart, thinking I'd at least salvage the brass. After I'd pulled all of the bullets and dumped the powder, I tried chucking the primed cases in a vice and then hit the primers with a pin punch and a hammer.

I found that some of the primers would "pop" but others would just sizzle and smoke. I'm pretty sure those were my hang fires. It was an interesting experiment

The last surplus ammo I had looked so bad that I never fired any of it. Like you, I took it apart. The powder was clumped together. The base of the bullet was green with corrosion. I decapped all the brass, burned the primers and powder outside when burning rubbish, and sold the brass and bullets to a scrap company. Recouped a very small amount of initial price. That was the last time I got fooled on surplus ammo crap.

My guess is that most of the foreign countries that are selling surplus goods to the USA, don't care much about how they handle or store the items, as long as it gets on the shipping container and they pocket the purchase price, they are happy. Caveat emptor is Latin for "Let the buyer beware." It especially applies to surplus goods that have a shelf life. Where was it stored? How was it stored? What temperature? Subjected to water or salt air? Exposed to a structure fire? How was it transported? Etc. etc...too many unanswered questions. A deal that is too good to be true, usually is too good to be true.

http://www.gunandgame.com/forums/powder-keg/38539-those-think-old-ammo-still-ok-print.html

For those that think old ammo is still ok....

A buddy of mine took his Sig p220 .45 down the range with us the other weekend. He had some old winchester hollowpoints that looked like they had been buried for 30 years. With myself still being new to guns and shooting, i didnt think anything about it.

Well he took one shot and it blow up in his hand. Now he has shot numerous rounds through this gun without a problem, of course they were new. Anyway, noone was hurt but the sig. This is hte way the gun is stuck in. It will not budge. Id say its a nice new paperwieght

http://www.thehighroad.org/showpost.php?p=7756780&postcount=6

Although it's remotely possible that a defective load (very unlikely if factory ammo) or poorly stored ammo that had deterioated. I had some H450 go bad and an "accuracy" load from a .30/06 w/180gr bullet locked up the bolt and removed case looked like a belted magnum...... but gun was unharmed.... primer was blown however and pitted the bolt face...... I pulled down the rest of the ammo and powder "stunk" like vinegar and inside of cases were turning green from acid corrosion..... Ammo had only been loaded 6mos earlier... and powder looked and smelled "ok" then.

http://www.ramanon.com/forum/showthread.php?57650-Bad-7-62x25-Ammo

Bad Bad 7.62x25 Ammo

You have probably read my recent thread on a CZ-52 and FTF problems. I expected it was the pistol that had the problem. A few days ago I took it to the range again with the same can of mil-surp ammo after polishing suspect surfaces in the pistol as the possible cause of its problem.

Right away I had the same FTF problem. The slide would not quite close all the way on a round. I had to nudge the slide fully into battery all too often.

So I began to think of other possible causes of the FTF and examined the ammo I was firing. I might have the answer. The surplus 7.62x25 ammo had cracks in the brass of unfired ammo! Often right where a dimple was is in the case that held the bullet head into the case. Sometimes sizeable cracks between the dimples.

Take a look at these unfired cartridges and the cracks. This defective ammo could explain my feeding problem…….

An example of powder that went bad in the can:

http://thefiringline.com/forums/showthread.php?p=4702804#post4702804

4895 gone bad? ________________________________________

I just opened a one pound can of IMR 4895, stamped E91 on the bottom (1991?) L7867. The can was sealed and stored in a cool, dry basement room. I immediately noticed a significant amount of fine brown dust throughout the power. It left a notable brown dust type substance on my power funnel, and I decided not to use it. I asked a friend and he has had the same thing (not sure if its actually the same stuff) in some 4831. I could just toss it out to play safe, but this stuff isn't that cheap anymore.

http://thefiringline.com/forums/showthread.php?t=472369