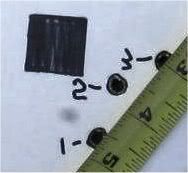

Howdy Cap&Baller. On the side where a shim (shim stock of brass or copper or even aluminum pie pan)would fit between the bolt head and the frame a flat shim stock is used and simply cut with scissors and rubbed flat and a hole punched in to fit the bolt screw thru. It stays between the bolt and the frame due to the trigger guard being there.

Bolts move some since the screw holes in them are usually a little too big. Naturally the bolt window in the frame has to allow movement and if it's too tight on the bolt head it needs filed carefully so when the shim moves the bolt over the bolt rides against that side of the window(not so tight as to bind the bolt against anything. The shim just has to be the right thickness.

On the other side of the bolt in front of the trigger and filling in that wide space a part or piece needs to be made. It fits the contour of the frames milled out area on one side and has a groove milled or filed in the side close to the bolt screw so that end straddles the bolts screw with more going under the screw than above. That keeps the new part in place but....if it moves up and down some it's still where it needs be and works to keep the bolt inplace.

Work one side or the other of the bolt moving it and checking the alignment by eye ballin down the barrel with a small flash light watching the "silver moon of misalignment" growing smaller till it's gone and the shim or shims(sometimes there would be a shim stock shim on the side where the bolt is next to the frame and the new made part/piece metal shaped to fit there on the other side where the open space is in front of the bolt screw and to the side of the bolt (sorta in front of the trigger). The flat face of the cylinder around the chambers reflects light back at a "gunsmith" (kitchen table extrourdinaire type) using a small flash light. There's a trick to it and the more you look in there the easier it is to see right at the place where the rifling grooves and the cylinder face meet. You want to learn to see the small little line of silver that would be in the beginning of each rifling groove because the chambers are slightly undersized. When each looks equal in each groove the alignment is pretty "on".

Going a little further yet there's the "black" reflected back that is the crown or bevel on the opening of each chamber. That's harder to see but it's there.It's just not silver reflecting back but it's black reflected back looking down the barrel. Get that "gone" too by turning the cylinder with the bolt to hold it where no silver or black shows looking down the barrel. When the chambers are reamed to be "groove diameter" size then when the silver and the black around the front edge of the chambers is gone it's aligned. When the chambers are smaller than groove diameter only the silver shows a thin line in each groove of the barrel and,if you look real close if the chambers are beveled you'll see black inside the sliver. If they are all equal looking the chambers are lined up good. I like when the chambers show only the sliver and not the black from the chamber bevels when the chambers aren't beveled.

Basically if you see the "silver moon of misalignment" you move the bolt till the silver is gone and ,if you want it better yet you'll see only the black from the bevels and you make those equal in size. Hopefully the bevels aren't those huge gaping "overly large bevels".

I've always noticed a marked difference to the good with accuracy after a cap&baller revolver is aligned better in the chamber bore area.

I hope that explains it clear enough.

What does this have to do with loads preferred in a cap&baller? I quess it is saying that the first step to loading a cap&baller rev is to make sure the chambers align to the bore so you can see when you have a good load and not a good load trying to over come misalignment. How can a Pard know a load is good when the gun isn't aligned good?

Sometimes when the alignment is really off all the tricks of the trade need be used. The shim between the bolt and frame, the part/piece on the open side between the bolt and the frame and in front of the bolt screw,a new bolt filed or stoned to be fitted only on one side so it moves the bolt over when the bolt head is fit to the cylinder notches. The bolts that are a little large for the cylinder notches can come from anywhere. Pietta makes some replacements like that and some Uberti's are like that and....Dixie Gun Works,bless their souls, usually sells overzied bolts that can be fit to a wide range of guns. You just have to look around and order some bolts and/or ask about whether or not they are sized to fit right in the cylinder notches or a little big and need fit to the notches. You may get an answer or NOT since parts people seem to think that's getting a little "picky".

I've aligned some guns that are so far "out" that I've had to get a spot of weld on the one side of the bolt and mill or file a shallow flat groove in the frame to accomodate the lopsided bolt head or.....if the bolt has weld put on the other side a lot of the bolt window in the frame needs filed/stones away till it can accomodate that bolt lopsided on the other side.That leaves a big space open on the other side of the bolt window and either a shjim or weld build up to weld and fit that side of the window over further....like adding metal to file and shape and move the window over. Take off one side and add to the other.

Sometimes when the alignment is at the top or the bottom looking down the barrel a new cylinder base pin(arbor) needs to be fit so the cylinder doesn't just lay on the base pin with a loose hole that lets the cylinder drop or.....if the cylinder needs to drop(silver shows at the bottom looking in the barrel).....the cylinder needs it's center hole opened up so it can drop or an over sized(just a little) base pin needs fit and the frame holes(Remington) need reamed to be a little lower when the new bigger base pin id fit. You have to look to see if a larger base pin can be fit with the frames holes moved in a Remington.

The Colts are simpler to move a cylinder up or down. A coupla spots of weld on the arbor can raise or lower a cylinder. The center hole of the cylinder may need reamed open a little more or it may already be loose enough.

You can move barrels on Colts with the qeld bumps filed or stoned smooth and the same and fit to the arbor hole in the barrel,especially if it's already loose to begin with(the hole in the barrel may not need opened up in the case of a "Loose caboose" barrel arbor hole. Sometimes a coupla bumps on the arbor can tighten the barrel on the arbor just right....as long as the cylinder can still go on. If the cylinder hole is opened up a little that lets the cylinder drop and that may make the gun out of alignment there.

I always say..."don't go anywhere till you know where you're going".

Anyway...some of these tips can help get a gun tuned to be ready to find the best load for the chambers so I guess checking your gun for fit is the first step to finding a preferred load.

All things being relative.....it's up to the owner of the gun what he/she wants. The forcing cone in a cap&baller revolvers barrel can be opened and elongated and made to alieviate some of the stress of an out of alignment chambers as long as thge misalignment isn't way too much....since it's the "ball" that's used in the cap&ballers. The conicals need a perfect alignment,or as close as possible, to shoot their best.

The cap&ballers,especially the Remingtons, can fling those conicals real well when......the conical is made to fit the dang barrel and isn't made undersized by the undersized chambers. Only a hollow based conical has a chance to be accurate when it's under sized compared to the barrels grooves.

The darn conicals or conical moulds can't always be used if they are undersized to begin with. Just like a Pard wouldn't shoot an under sized conical from his cartridge gun he shouldn't do that with his cap&baller. If the barrels grooves aren't abnormally large diameter and close to nominal 45cal size like .451-2-3-4 in. a Lee oversized .456 ma6y be made to shoot well......if the chambers are sized to be at groove diameter or .001-.002 over that. Right at is plenty good though. Barrels grooves diameter at .451? Then the chambers should be .451 in. too. Never more than .002 in. oversized. Some say the lead bullets are better sized for accuracy when they are .001 or .002 in. over the groove diameter in the barrel. Hope this helps Cap&Baller.

I forgot to add....those little rubber "Cap Guards" are sold at places that sell muzzleloading loading supplies. I have a coupla packs some good friend gave me to try. I tried them years ago. They do what the caps of yesteryear most likely did. Not flay out all over the place and hang the guns up and all that. Those "Cap Guards" work. The ones sold commercially are red. Red of all things.:barf: Black would be nicer.