Meatsaw and Hardcase

MS,

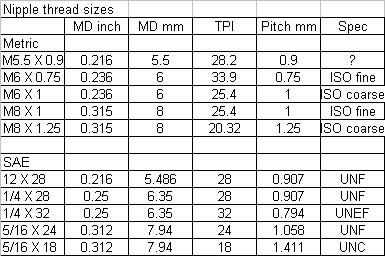

I did not replace the nipples but they are a coarser thread than Pietta. I did not bother to check the threads but I think that if Mykeal is reading this thread he will wade in with a cross reference of nipple sizes for the different Italian manufacturers.

HC,

That is a darned fine drill press. Problem with that press is that there are a lot of variables.

1. The head needs to be tightened down real snug

2. The table needs to be snug too and squared with the spindle (which I think is easy on that press.)

3. I have not found a good two axis vice for less than about three hundred bucks. The vice needs to be held very tight onto the table. This arrangement actually simplifies milling slightly because the axis of the jaws is automatically at quadrature with the movement of the vice in its two axis of motion. Clamping a vice to a milling machine is a set-up process in its own right.

4. A drill press chuck is not generally designed to hold cutting tools but you can make it tight enough it you jack on the chuck key enough.

5. I do not know if the spindle of the drill press can be locked in a fixed position. This is important unless you have three hands.

6. Drill presses are generally not substantial such as to withstand much side force. A lathe suffers from the same deficiency. (This is why bump knurling is not recommended using a lathe.) So if you try to do much milling it should be only light duty milling. The nice thing about your particular drill press, is that it is a very good one and if any press can take it, yours can.

My recommentation is to get yourself a cheap vice like one from Harbor Freight and get some cheap general purpose end mills. Set up some scrap stock and see how you feel about the noise coming from the drill press.

Then, once you are comfortable with the way your set up is performaing you will know whether or not to put more money into a better vice.

BUT

The cost of the milling machine is only a small part of the investment. You can easily have as much money into trying to use your drill press as a mill as you would have just going out and buying a used mill.

I gave $400.00 plus two old rifles for mine. It is a Grizzly two horse bench model. It is the biggest mill they make for a bench and I would not want anything smaller. Weighs seven hundred pounds. The lathe is a Grizzly 10 by 22 which I bought new. Neither of the machines are extremely precise but for what I paid for them I can get used to it.

Do not....I say again.....Do not make the miostake of buying a combination lathe mill drill.

MS,

I did not replace the nipples but they are a coarser thread than Pietta. I did not bother to check the threads but I think that if Mykeal is reading this thread he will wade in with a cross reference of nipple sizes for the different Italian manufacturers.

HC,

That is a darned fine drill press. Problem with that press is that there are a lot of variables.

1. The head needs to be tightened down real snug

2. The table needs to be snug too and squared with the spindle (which I think is easy on that press.)

3. I have not found a good two axis vice for less than about three hundred bucks. The vice needs to be held very tight onto the table. This arrangement actually simplifies milling slightly because the axis of the jaws is automatically at quadrature with the movement of the vice in its two axis of motion. Clamping a vice to a milling machine is a set-up process in its own right.

4. A drill press chuck is not generally designed to hold cutting tools but you can make it tight enough it you jack on the chuck key enough.

5. I do not know if the spindle of the drill press can be locked in a fixed position. This is important unless you have three hands.

6. Drill presses are generally not substantial such as to withstand much side force. A lathe suffers from the same deficiency. (This is why bump knurling is not recommended using a lathe.) So if you try to do much milling it should be only light duty milling. The nice thing about your particular drill press, is that it is a very good one and if any press can take it, yours can.

My recommentation is to get yourself a cheap vice like one from Harbor Freight and get some cheap general purpose end mills. Set up some scrap stock and see how you feel about the noise coming from the drill press.

Then, once you are comfortable with the way your set up is performaing you will know whether or not to put more money into a better vice.

BUT

The cost of the milling machine is only a small part of the investment. You can easily have as much money into trying to use your drill press as a mill as you would have just going out and buying a used mill.

I gave $400.00 plus two old rifles for mine. It is a Grizzly two horse bench model. It is the biggest mill they make for a bench and I would not want anything smaller. Weighs seven hundred pounds. The lathe is a Grizzly 10 by 22 which I bought new. Neither of the machines are extremely precise but for what I paid for them I can get used to it.

Do not....I say again.....Do not make the miostake of buying a combination lathe mill drill.

Last edited: