The power supply will not be easy. I had given some thought to using a PC PSU with a real beefy 12 Volt rail. Been awhile since I did much with PC PSUs and the use of them for other projects. If memory serves me correctly some use multiple 12 V rails as in 12V1, 12V2, 12V3 and whatever while some boasted a single 12 Volt rail. Should a 12 V ATX form factor PSU work for powering an induction heater? I would think it should. That is the only inexpensive 12 Volt high current supply I can come up with off hand. It has been about 6 years since I looked at any of the stuff.

I do have an old either Sorenson or HP bench type supply laying down at my sister's house (my mom's old house) and my brother texted me the name plate data which is 10 - 60 Volts and 0 to 18 Amps. That thing weighs over 100 Lbs. SMPS has its merits. Last I saw it run was around '97 or '98.

Using a PC ATX form factor or similar PSU should work. I am not sure how placing multiple rails on parallel will work out and I am not sure what the inrush current to a induction heater circuit will look like. Meaning will the PSU current limit and shut down before it gets going?

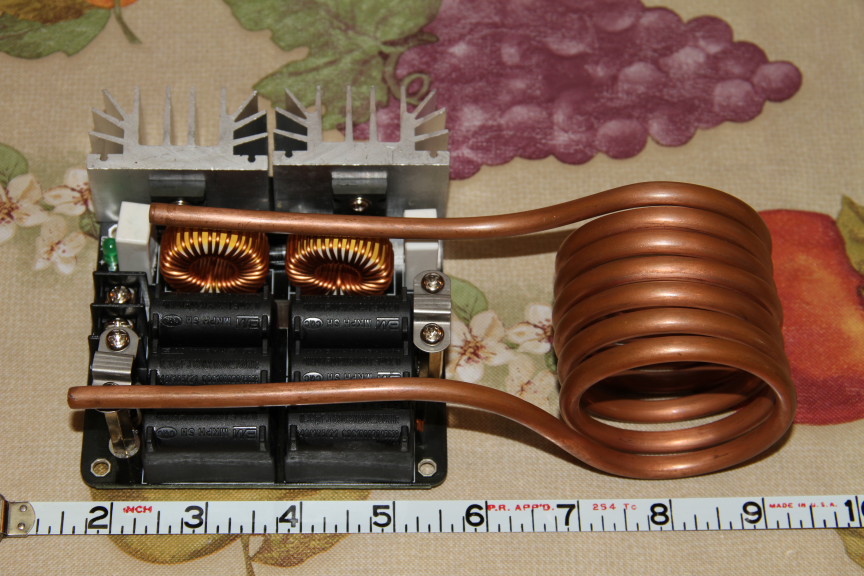

Using 12 Volt power the current demand, even for a 500 watt induction heater comes in at just over 40 Amps. Depending on the output stage be it MOSFET or IGBT it would likely be better to run 24 Volts and that way you can use a lower current. Using an ATX or server 1U or 2U PSU may require an external small load on the 3.3 volt bus so the thing can regulate. Again, it has been years. Using a pair of MOSFETs the current draw will be a function of the voltage applied to the MOSFETs making up the load driving the coil.

I plan to play around with this but not before mid February after I get the hell out of this icebox for several weeks and return.

Ron

I do have an old either Sorenson or HP bench type supply laying down at my sister's house (my mom's old house) and my brother texted me the name plate data which is 10 - 60 Volts and 0 to 18 Amps. That thing weighs over 100 Lbs. SMPS has its merits. Last I saw it run was around '97 or '98.

Using a PC ATX form factor or similar PSU should work. I am not sure how placing multiple rails on parallel will work out and I am not sure what the inrush current to a induction heater circuit will look like. Meaning will the PSU current limit and shut down before it gets going?

Using 12 Volt power the current demand, even for a 500 watt induction heater comes in at just over 40 Amps. Depending on the output stage be it MOSFET or IGBT it would likely be better to run 24 Volts and that way you can use a lower current. Using an ATX or server 1U or 2U PSU may require an external small load on the 3.3 volt bus so the thing can regulate. Again, it has been years. Using a pair of MOSFETs the current draw will be a function of the voltage applied to the MOSFETs making up the load driving the coil.

I plan to play around with this but not before mid February after I get the hell out of this icebox for several weeks and return.

Ron