Dufus, you're telling me that out of the thousands of .45, 9mm. makarovs, and other military things that were cranked out over the years, there haven't been numerous chambers that were bored terribly, and left with reamer rings, just the thing to lock a case in so hard that it should have done that exact thing? It would be just like a threaded bolt on a nut.

Of course rough chambers exist. but we're talking about dirt being enough to pull a casing apart at the center, ripping it in half because there was resistance. I'm just not believing that is possible. As I said, how often has anyone seen a case ripped in half on a reloading die that was stuck?

NEVER, EVER HEARD OF IT. Doesn't the brass usually tear apart at the shell holder?

Not at all the same situation, being as the case head was pushed apart, maybe, but there doesn't seem to be any indication that it was pulled apart when the extractor yanked it out when the recoil pulled the slide back. but still, it's a matter of that case head being pulled apart at the middle and that just doesn't make sense, since the entire case should have had equal pressure all the way front to back. Yes, there is a slight taper, but even that doesn't appear to make sense. Why did it happen in that place, in a perfect ruing, just because it was tapered?

Everyone knows that brass is malleable. It stretches every direction when fired. I'm not seeing any evidence of stretching at all, just complete and simple failure in a perfect ring.

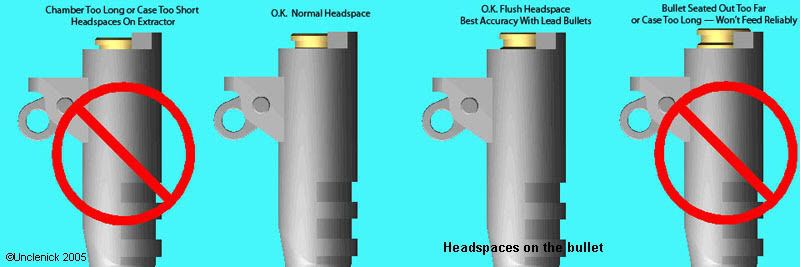

Am I the only one that is seeing two rings on that loaded round? one at the base of the bulet, and a faint one right where the tear started?

One last question. Does the recoil action actually start before the round has left the chamber? Never mind, I just looked it up, the bullet is long underway, that pressure should have been vented, and any pressure that remained on the walls of the brass should have been gone.

I don't think that this is the answer.

http://www.thefirearmblog.com/blog/2015/08/18/1911-fired-at-73000-frames-per-second/