Your headspace gauge tells you if your case meets SAAMI standards, but those standards allow for a degree of interference fit as the bolt squeezes the case and it expands to fit the chamber. If you look at

the SAAMI drawing for 30-06, you will see the maximum case head-to-shoulder datum dimension (upper drawing) is longer than the minimum chamber breech face to shoulder datum dimension (lower drawing). A comparator, like the

case inserts for a Hornady comparator, or the improvised case comparator below, will let you see whether you have actually sized the case shorter than it came out of the chamber. The headspace gauge will guarantee that it can fit, but the comparator shows you if that fit will be easy or not.

Note that 30-06 may need a slightly narrow spacer as they tend to be bored oversize. That on measured 0.410" ID. I've used a 3/8" (0.375") bronze bushing journal for .30-06 before, and that works well.

Mendozer said:

Once I fire brass in my chamber, isn't it technically going to conform to my chamber?

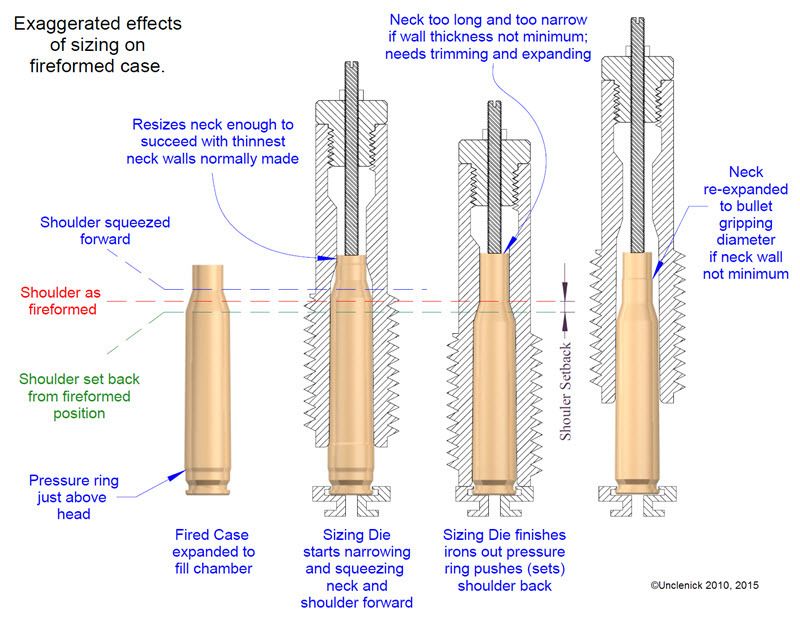

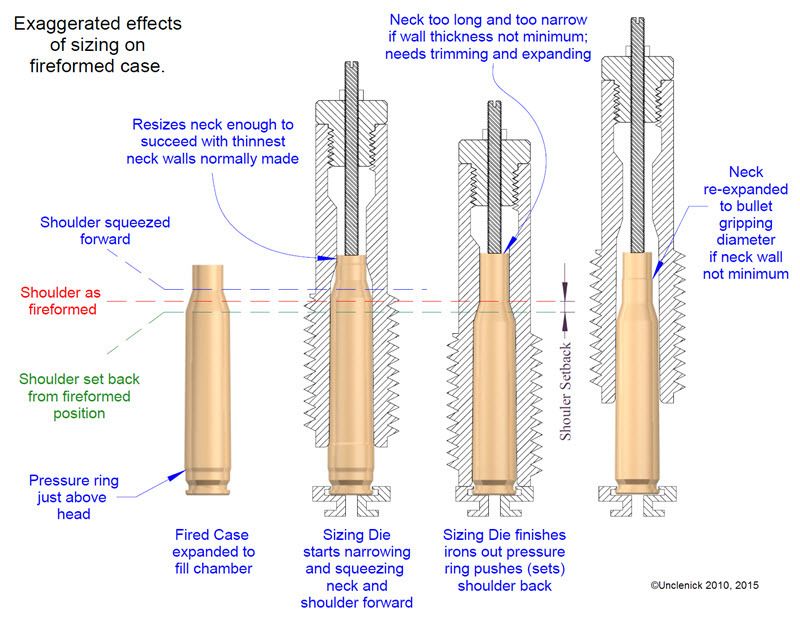

Only when neck sizing-only. Full length sizing a bottleneck case first makes it longer then shorter again after the die shoulder pushes the shoulder back (see below).

So, the problem can be that the length from the casehead to the shoulder is too long to fit your chamber if the case wasn't driven far enough up into the die. If there is any gap between the top deck of the shell holder and the mouth of the die at the top of the sizing stroke, even a crack of light (see this Lee help video for how to check for this) tightening the die down will help. However, if the die and shell deck already make solid contact at the top of the stroke, it won't help. You then want to try F. Guffey's method to test for a tall die or a short chamber. Remove the decapper from the die and slip a feeler gauge between the case head and the bottom of the shell holder slot. Try 0.001" then see how a case fits your chamber. If it's still firm, try 0.002". The feeler gauge drives the case deeper into the sizing die by the thickness of the gauge. Keep testing gauges until you find what is needed to get a fit. Usually, however, it turns out to be die adjustment.

If you are into brewing, you probably visit a beer and wine making supplier from time to time. Get a little citric acid there. If it's expensive, you can get it in Ball brand among the canning supplies at Walmart in the fall. Dissolve two tablespoons in a gallon of water. This is very close to the formula Hornady sells for ultrasonic case cleaning after dilution. You can add a few drops of dishwashing liquid to help wet and suspend dirt if you want to. Simple Green is probably too alkaline and might neutralize the acidity, but you can experiment. The citric acid not only cleans well, it leaves the surface of the brass relatively passivated so it doesn't corrode easily. If you like how this works there are much less expensive sources of larger quantities of citric acid. I bought 10 lbs for less than

$25 postpaid from here; enough for 200 gallons of cleaning solution at about 12.5 cents a gallon).