I may be missing it on yours but there should be a flattened area on the arbor where the hand passes it. I had a new Navy that was not done, it would work but was tight.

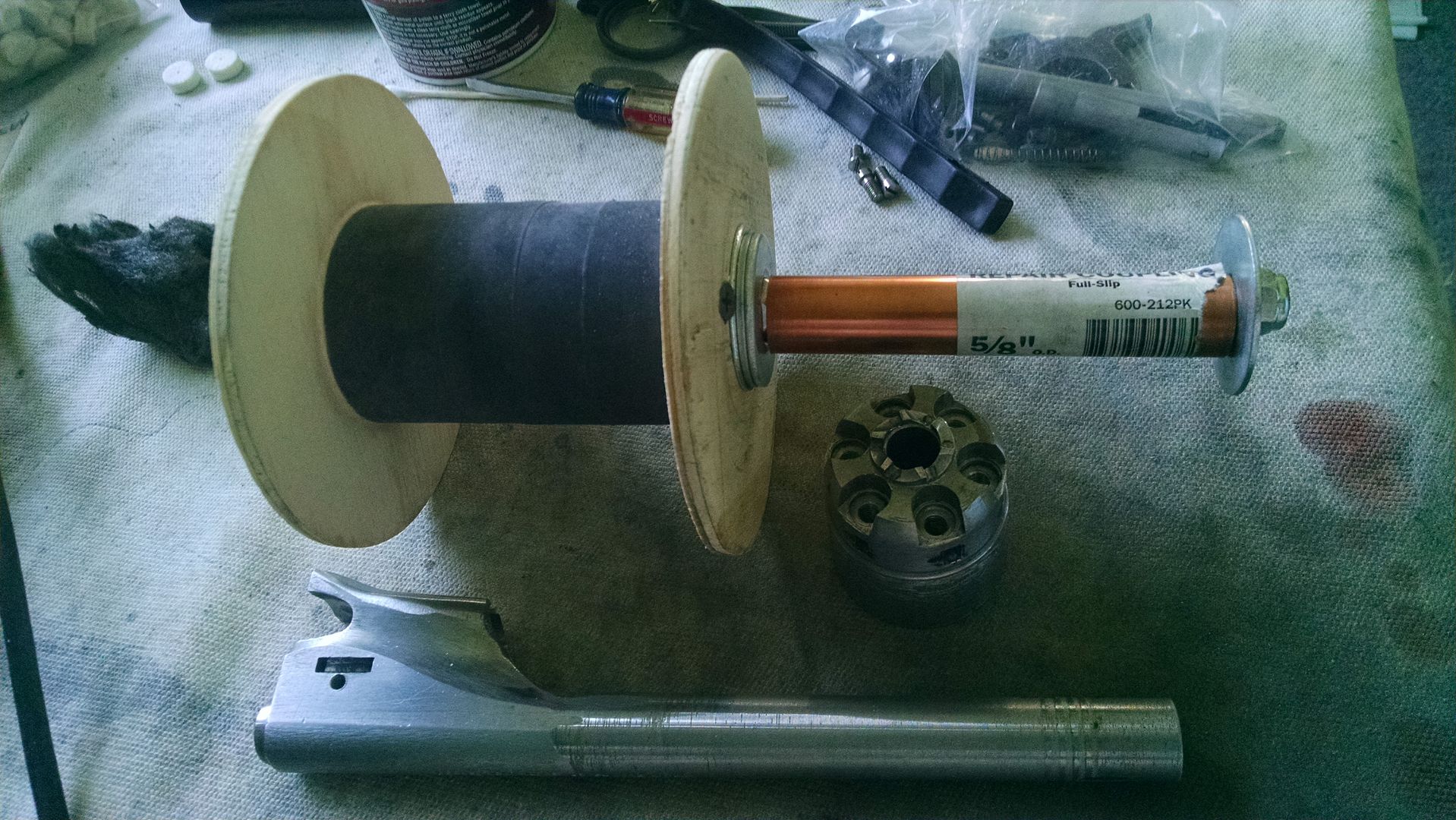

Uberti has a flat spot. Pietta has a step down in arbor diameter there.

I may be missing it on yours but there should be a flattened area on the arbor where the hand passes it. I had a new Navy that was not done, it would work but was tight.

I have a take off Pietta frame with a short arbor.