( if this is the wrong place to drop this -- I'm sure It will be moved  )

)

In our S.A.F.E. group - the woman who runs our Women on Target classes - adult son died --

She just got around to cleaning out his safe & sold a bunch of handguns and rifles she'd never use --

The other night she gave me a CVA - 1861 Colt Navy kit ( ASM ) --

My plan as of now is to build it - make a nice box & give it back to her

( as my Pappy said -- "When you ever get to the point - raise your hand" --

)

)

99.9% of the parts were in a bag -- Allen must have bought this in the late "80's" ?

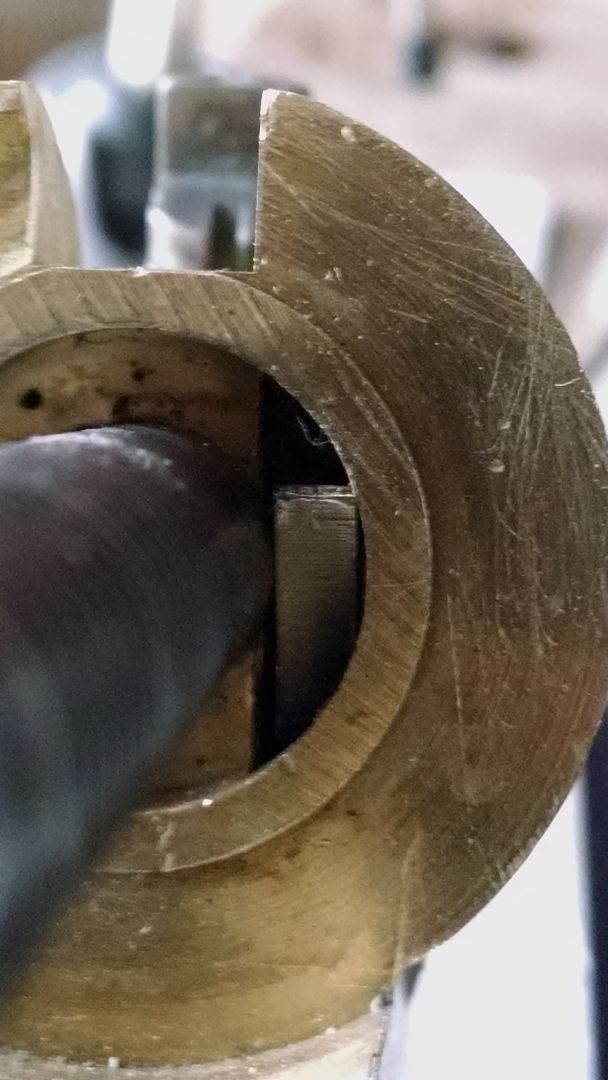

I just ordered a brass back strap for it --- test assembling it --

Pull the hammer back either very slow or fast - 1/2 cock first click - fine - second little click - fine ---- third - hammer back locking click - good -- pull the trigger -- great --

But if I just drop the barrel on to the spindle & point it up -- first click - fine - bolt release is retracted and the barrel will free spin --

When I pull the hammer back to lock it in the firing position -- it wont hold there - it moves forward to 1/2 cock ????

Remove the barrel - its good ?

I even filed a tinny bit where the hand slides in the frame in case it was binding a wee-bit --

Any suggestions ?

In our S.A.F.E. group - the woman who runs our Women on Target classes - adult son died --

She just got around to cleaning out his safe & sold a bunch of handguns and rifles she'd never use --

The other night she gave me a CVA - 1861 Colt Navy kit ( ASM ) --

My plan as of now is to build it - make a nice box & give it back to her

( as my Pappy said -- "When you ever get to the point - raise your hand" --

99.9% of the parts were in a bag -- Allen must have bought this in the late "80's" ?

I just ordered a brass back strap for it --- test assembling it --

Pull the hammer back either very slow or fast - 1/2 cock first click - fine - second little click - fine ---- third - hammer back locking click - good -- pull the trigger -- great --

But if I just drop the barrel on to the spindle & point it up -- first click - fine - bolt release is retracted and the barrel will free spin --

When I pull the hammer back to lock it in the firing position -- it wont hold there - it moves forward to 1/2 cock ????

Remove the barrel - its good ?

I even filed a tinny bit where the hand slides in the frame in case it was binding a wee-bit --

Any suggestions ?

Last edited: