condor bravo

New member

Guffey:

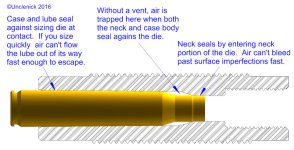

My premise of the air flow is opposite to what you have stated. I maintain that as the case is being raised into the die, the outside trapped air is pushed upwards and then vented down the case neck for the split second that the neck is open before sizing begins and then outwards through the open primer pocket, thereby closely equalizing outside and inside pressure. Since we can't observe the air flow, who can say what is actually happening? But the bottom line is that the process works and the denting has been eliminated.

My premise of the air flow is opposite to what you have stated. I maintain that as the case is being raised into the die, the outside trapped air is pushed upwards and then vented down the case neck for the split second that the neck is open before sizing begins and then outwards through the open primer pocket, thereby closely equalizing outside and inside pressure. Since we can't observe the air flow, who can say what is actually happening? But the bottom line is that the process works and the denting has been eliminated.