So, I'm interested in a good deal on a "car gun," and I'd be happy with a .40S&W for that purpose, since it wouldn't do range duty super often. However, I don't consider saving $50 or so to be much of a deal. I'd be interested in a very good condition used gun for about 50-60% of new. More than that, and it's not exactly a smoking hot deal, it's just an OK deal. For reference, I paid $250 for a 9mm M&P Shield w/ 5 magazines and 2 Sneaky Pete custom holsters. That's a good deal.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

40S&W not so popular?

- Thread starter t45

- Start date

* * * I don't consider saving $50 or so to be much of a deal. I'd be interested in a very good condition used gun for about 50-60% of new. More than that, and it's not exactly a smoking hot deal, it's just an OK deal.

It's all about the art of the deal.

For reference, I paid $250 for a 9mm M&P Shield w/ 5 magazines and 2 Sneaky Pete custom holsters. That's a good deal.

$250? Jeez-louise, that's a smokin' deal right there.

I've got a plastic rifle stock repair sitting in my safe right now...

waiting on me to delicately fix it to be invisible...

plastic is not as durable as some think it is...

and plastic degradation over time is a fact.

Heck, try leaving a Remington Nylon Rifle in the back window of

a car in summertime...it'll give you all the melted evidence

you'll ever want to see.

How many Gen 1 Glocks are still functional under regular use??

How many have been completely shot out and are useless??

How many all-metal guns are still going after a century??

How many Glocks will still be shootable in 50 years?? 100Years??

Plastic guns are still temporary tools,

ever changing and improving the formula helps...

but they're still Temporary, compared to all-metal.

waiting on me to delicately fix it to be invisible...

plastic is not as durable as some think it is...

and plastic degradation over time is a fact.

Heck, try leaving a Remington Nylon Rifle in the back window of

a car in summertime...it'll give you all the melted evidence

you'll ever want to see.

How many Gen 1 Glocks are still functional under regular use??

How many have been completely shot out and are useless??

How many all-metal guns are still going after a century??

How many Glocks will still be shootable in 50 years?? 100Years??

Plastic guns are still temporary tools,

ever changing and improving the formula helps...

but they're still Temporary, compared to all-metal.

TheGuyOfSouthamerica

Moderator

Big shrek I believe is closer to the thruth than do all the Plastik worshippers.

If Plastik is degradading in sunlight over time then that is not an idea to be used on guns except These modular Systems like the SIG P250, Beretta Nano and Beretta Pico.

If you put Plastik in a gun make sure the consumer can get spare parts easily. The rest of the gun in that case should be stainless steel and of an beefy Metall in order to insure Long Lasting.

As I understood James Yeager got his negative Impression about high pressure caliber pistols from his Long Shooting classes and he says: <<high pressure caliber pistols just don't hold up. Even Glocks.>>.

https://www.youtube.com/watch?v=Gsxdk1V8i-M

http://www.wdrb.com/story/29078319/bardstown-police-replacing-guns-after-dangerous-defects-found

On the other Hand the posting LE or Military People have their experiences as well but sometimes an Police officer in his whole carrier may not get involved in any Shooting whatsoever; just the regular one box Shooting Training each month.

If Plastik is degradading in sunlight over time then that is not an idea to be used on guns except These modular Systems like the SIG P250, Beretta Nano and Beretta Pico.

If you put Plastik in a gun make sure the consumer can get spare parts easily. The rest of the gun in that case should be stainless steel and of an beefy Metall in order to insure Long Lasting.

As I understood James Yeager got his negative Impression about high pressure caliber pistols from his Long Shooting classes and he says: <<high pressure caliber pistols just don't hold up. Even Glocks.>>.

https://www.youtube.com/watch?v=Gsxdk1V8i-M

http://www.wdrb.com/story/29078319/bardstown-police-replacing-guns-after-dangerous-defects-found

On the other Hand the posting LE or Military People have their experiences as well but sometimes an Police officer in his whole carrier may not get involved in any Shooting whatsoever; just the regular one box Shooting Training each month.

Last edited:

Charlie Fox

New member

I carried and qualified with the G22 in .40 back in the day - loved the platform but could never warm up to the caliber. I had carried a .45 up to the department mandating the above combination and I shot it well, but I never could get the same level of competency with the .40; I found it too snappy. When I retired I went back to 9mm because I knew I could shoot it faster and straighter than either the .40 or .45. My point is that if one is willing to take the time and practice, the .40 might be a good caliber. But most cops (and civilians) don't or won't. Anecdotally the round is very effective- several shootings in my former state resulted in one shot stops and/or the bad guy being put down immediately. I've been looking at getting another .40 only because ammo is getting cheaper

40S&W not so popular?

As has been pointed out, multiple times now, it's not the operating pressure. It has the same SAAMI spec as 9mm. James Yeager used the wrong word. The officer in that article used the wrong word. Yes it's a heavier bullet and yes it's more powder, but the volume of the case is changing.

https://thefiringline.com/forums/showpost.php?p=3070550&postcount=5

If your car gets to 300 degrees Fahrenheit by sitting in the sun then you have some problems

https://thefiringline.com/forums/archive/index.php?t-64581.html

As for durability, I think hundreds of thousands of rounds is pretty decent:

http://www.northeastshooters.com/vbulletin/threads/77078-Glock-19-with-750-000-rounds

If you prefer more of a firsthand account you can message AK103K here who has over 100,000 rods through his personal Glock. You can find other such examples by doing a simple search on Google.

We've gone from saying recoil is more preferable out of heavier pistols to questioning the strength of materials that have been around for 30+ years. Maybe back up the crazy train?

Sent from my iPhone using Tapatalk

As I understood James Yeager got his negative Impression about high pressure caliber pistols from his Long Shooting classes and he says: <<high pressure caliber pistols just don't hold up. Even Glocks.>>.

As has been pointed out, multiple times now, it's not the operating pressure. It has the same SAAMI spec as 9mm. James Yeager used the wrong word. The officer in that article used the wrong word. Yes it's a heavier bullet and yes it's more powder, but the volume of the case is changing.

https://thefiringline.com/forums/showpost.php?p=3070550&postcount=5

If your car gets to 300 degrees Fahrenheit by sitting in the sun then you have some problems

https://thefiringline.com/forums/archive/index.php?t-64581.html

As for durability, I think hundreds of thousands of rounds is pretty decent:

http://www.northeastshooters.com/vbulletin/threads/77078-Glock-19-with-750-000-rounds

If you prefer more of a firsthand account you can message AK103K here who has over 100,000 rods through his personal Glock. You can find other such examples by doing a simple search on Google.

We've gone from saying recoil is more preferable out of heavier pistols to questioning the strength of materials that have been around for 30+ years. Maybe back up the crazy train?

Sent from my iPhone using Tapatalk

Last edited:

TheGuyOfSouthamerica

Moderator

Over here it can become well over 100 degrees Farenheit in the sun and even in shade. Not to speak how much in an enclosed Container like the interior of an car.

I would not want to shoot an Plastik gun which is 120 Farenheit hot due to fear of weakening of the plastiks. Even less an high pressure caliber Plastik gun.

I would not want to shoot an Plastik gun which is 120 Farenheit hot due to fear of weakening of the plastiks. Even less an high pressure caliber Plastik gun.

Over here it can become well over 100 degrees Farenheit in the sun and even in shade. Not to speak how much in an enclosed Container like the interior of an car.

Yea it gets hot here too. I'm not sure you grasp how hot 300 degrees is. The rest of the interior of the car would be melted. You're talking way outside just a hot day. For that matter that isn't even the melting point. It's simply the point at which the polymer starts getting moldable.

I would not want to shoot an Plastik gun which is 120 Farenheit hot due to fear of weakening of the plastiks. Even less an high pressure caliber Plastik gun.

If you can hold on to something 120 degrees more power to you. Again though, that's still not hot enough for it to lose it's shape or even start to deform.

You don't understand what pressure is.

Last edited:

* * * I would not want to shoot an Plastik gun which is 120 Farenheit hot due to fear of weakening of the plastiks. Even less an high pressure caliber Plastik gun.

Wow, ... so leaving a loaded Glock 20 in your trunk for two days in the summertime would give you the equivalent of a hand-held 10mm nuke (?)

People will believe what they want. Most of us make up our minds and don't want to be bothered with a bunch of facts. Polymer pistols have proven to be reliable and durable in all field conditions. Comparing a cheap nylon rifle stock to a well made polymer handgun is apples and oranges.

TheGuyOfSouthamerica

Moderator

This is pressure:

https://thefiringline.com/forums/showpost.php?p=3070550&postcount=5

P=powder Charge/Volumen of case. temperature and konstant are constants.

I may add the bullet weight to the formula Kind of this:

Pressure = (powder+bullet weight)/empty air Volumen of case.

I have read on some Posts that Pressure is defined as the energy exerted upon square Inch of the bullet. But the bullet starts to move quicker if it's lighter; if the mass of the bullet is greater more energy must be exerted upon it to move the bullet with the same timeframe.

Modified pressure formula

Pressure = energy (powder) exerted upon square Inch of an bullet base + mass (weight) of the bullet.

The greater the bullet Diameter the lesser is the pressure ceteris paribus (constant) powder Charge and weight of bullet.

What is wearing out an 40 S&W, 357 SIG, 10mm is the greater powder Charge and heavier bullet mass exertes more backpressure to the slide since it creates more pressure in order to get to over 500 ft/lbs of energy Levels. Any force foreward (bullet energy) creates equal force backward (recoil, slide movement backward, gun wear).

357 SIG has the same square Inch bullet base as the 9mm Luger but way more powder (force behind it). [high pressure round]

40 S&W and 10mm have just slighly more square Inch bullet base Diameter as the 9mm Luger has but way more powder (force behind it). [high pressure round]

45 acp has an bigger square Inch bullet base as the 9mm Luger and a bit more powder. [low pressure round]

You see the bullet weight must be added to the formula as well as an factor.

https://thefiringline.com/forums/showpost.php?p=3070550&postcount=5

P=powder Charge/Volumen of case. temperature and konstant are constants.

I may add the bullet weight to the formula Kind of this:

Pressure = (powder+bullet weight)/empty air Volumen of case.

I have read on some Posts that Pressure is defined as the energy exerted upon square Inch of the bullet. But the bullet starts to move quicker if it's lighter; if the mass of the bullet is greater more energy must be exerted upon it to move the bullet with the same timeframe.

Modified pressure formula

Pressure = energy (powder) exerted upon square Inch of an bullet base + mass (weight) of the bullet.

The greater the bullet Diameter the lesser is the pressure ceteris paribus (constant) powder Charge and weight of bullet.

What is wearing out an 40 S&W, 357 SIG, 10mm is the greater powder Charge and heavier bullet mass exertes more backpressure to the slide since it creates more pressure in order to get to over 500 ft/lbs of energy Levels. Any force foreward (bullet energy) creates equal force backward (recoil, slide movement backward, gun wear).

357 SIG has the same square Inch bullet base as the 9mm Luger but way more powder (force behind it). [high pressure round]

40 S&W and 10mm have just slighly more square Inch bullet base Diameter as the 9mm Luger has but way more powder (force behind it). [high pressure round]

45 acp has an bigger square Inch bullet base as the 9mm Luger and a bit more powder. [low pressure round]

You see the bullet weight must be added to the formula as well as an factor.

Last edited:

You're missing the importance of the volume of the case in your explanation. As I said, yes there is more powder charge. Yes the bullet is heavier. But the volume of the case also changes. That's why the SAAMI spec shows them with the same pressure ceiling. We don't need to debate this you can get the data right from SAAMI:

http://www.saami.org/specifications_and_information/VelocityPressureData.pdf

I'm aware of Newton's laws. There is a force exerted on the slide (which if you want to divide by the breechface area you can consider it as a pressure) and then a gas pressure within the cartridge case itself. They're not the same. Then as you pointed out there is a force exerted on the bullet as well. That's why just saying "pressure" isn't clear enough in a system that involves interacting parts. There are multiple objects having force exerted on them. To which do you refer?

My comment would be you mean to say there is more force exerted upon the slide. That's the same comment I would make to Yeager. Saying pressure when it typically refers to the gas pressure within the cartridge when you mean the force exerted on the slide leaves you open to problems with interpretation.

I'd point out we're also now getting into more of an ammunition/reloading question and have walked well off the reservation. None of this changes the durability of polymer, how different people perceive recoil, etc.

http://www.saami.org/specifications_and_information/VelocityPressureData.pdf

Any force foreward (bullet energy) creates equal force backward (recoil, slide movement backward, gun wear).

I'm aware of Newton's laws. There is a force exerted on the slide (which if you want to divide by the breechface area you can consider it as a pressure) and then a gas pressure within the cartridge case itself. They're not the same. Then as you pointed out there is a force exerted on the bullet as well. That's why just saying "pressure" isn't clear enough in a system that involves interacting parts. There are multiple objects having force exerted on them. To which do you refer?

My comment would be you mean to say there is more force exerted upon the slide. That's the same comment I would make to Yeager. Saying pressure when it typically refers to the gas pressure within the cartridge when you mean the force exerted on the slide leaves you open to problems with interpretation.

I'd point out we're also now getting into more of an ammunition/reloading question and have walked well off the reservation. None of this changes the durability of polymer, how different people perceive recoil, etc.

Last edited:

What is wearing out an 40 S&W, 357 SIG, 10mm is the greater powder Charge and heavier bullet mass exertes more backpressure to the slide since it creates more pressure in order to get to over 500 ft/lbs of energy Levels. * * *

Okay, after reading the last two pages of this shiznitz, I'm loading my G20 with 15-rds of the high-n-hard stuff and sending it by boat to So. America in the trunk of an old car with the heater turned up full-blast.

If it nukes at some point, ... well, then maybe this dudenal's on to something.

Last edited:

Slide velocity is what wears out/breaks properly designed semi-auto pistols, not actually pressure.

Slide velocity is a result of the conservation of momentum. That is to say, it is proportional to the momentum of the ejecta. The momentum of the ejecta is the mass velocity product of what comes out of the muzzle.

Focusing on pressure in a properly designed pistol usually isn't going to provide useful insight into durability.

Slide velocity is a result of the conservation of momentum. That is to say, it is proportional to the momentum of the ejecta. The momentum of the ejecta is the mass velocity product of what comes out of the muzzle.

Focusing on pressure in a properly designed pistol usually isn't going to provide useful insight into durability.

TheGuyOfSouthamerica

Moderator

I believe the strength/durability of an 40 S&W and other high pressure rounds compared to an 9mm Luger pistol is the mass/strength of the slide and Barrel (were it lockes).

Like stated as well already Dhart and JohnKSa:

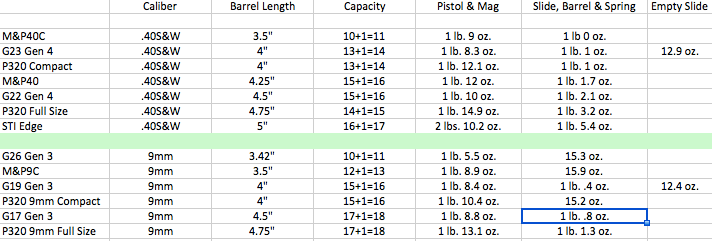

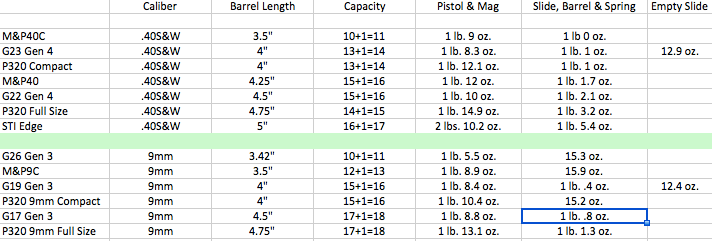

The above Chart is the clue and the weightings of JohnKsa.

Both conclude that the modern slides and Barrel of the high pressure calibers and low pressure calibers are almost the same.

So for the high pressure calibers way more pressure and inertia is exerted upon slide and Barrel (assuming lock breech JMBrowning design) since These parts are just as thick as on the 9mm Luger guns.

Clearly this states that modern high pressure caliber pistols are only beefed up 9mm Luger pistols. Even worse: These data state those pistols are built on the "Chassis" of an 9mm Luger pistol.

No wonder James Yeager finds high pressure caliber Plastik pistols wear way faster out than 45 acp or 9mm Luger pistols. It's like mounting an motorcycle onto an bycicle Frame. Or like mounting an towing truck onto an passenger car Frame.

If you want 40 S&W caliber guns please double the thickness of the rails, slide, Barrel and any locking mechanism upto about doubling the weight and you should be fine. Same applies for 357 SIG and 10mm. An high pressure pistol should weight about 40 oz and no less.

Like stated as well already Dhart and JohnKSa:

The above Chart is the clue and the weightings of JohnKsa.

Both conclude that the modern slides and Barrel of the high pressure calibers and low pressure calibers are almost the same.

So for the high pressure calibers way more pressure and inertia is exerted upon slide and Barrel (assuming lock breech JMBrowning design) since These parts are just as thick as on the 9mm Luger guns.

Clearly this states that modern high pressure caliber pistols are only beefed up 9mm Luger pistols. Even worse: These data state those pistols are built on the "Chassis" of an 9mm Luger pistol.

No wonder James Yeager finds high pressure caliber Plastik pistols wear way faster out than 45 acp or 9mm Luger pistols. It's like mounting an motorcycle onto an bycicle Frame. Or like mounting an towing truck onto an passenger car Frame.

If you want 40 S&W caliber guns please double the thickness of the rails, slide, Barrel and any locking mechanism upto about doubling the weight and you should be fine. Same applies for 357 SIG and 10mm. An high pressure pistol should weight about 40 oz and no less.

The locking surfaces are about the same dimensions in both 9mms and .40S&W which works out well since the pressures are the same as well. The locking surfaces need to resist discharge pressure and since discharge pressure is identical between 9mm and .40S&W, it's fine for the locking surface area to be the same in both calibers.So for the high pressure calibers way more pressure and inertia is exerted upon slide and Barrel (assuming lock breech JMBrowning design) since These parts are just as thick as on the 9mm Luger guns.

What is different between the two guns is the slide velocity, not the discharge pressure. Slide velocity will "hammer" the parts that interrupt and/or stop the slide and barrel as they travel backwards. So the locking block and lower barrel lug tend to take more stress in a .40S&W gun than in a 9mm gun. Similarly, since the recoil springs tend to be stiffer, they return the slide to battery more violently and that can result in peening as the slide and barrel lock together.

However, very little of that has anything to do with stress on the frame. The stressed parts in a recoil-operated pistol are generally steel, not plastic. The plastic parts are generally not significantly stressed and therefore they hold up very well in properly designed guns.

This is borne out by failure reports on .40S&W and .357SIG guns. Usually they are things like broken locking blocks/broken locking block pins or other similar parts. To the extent that there are reports of plastic frames breaking, the reports seem to be about the same across all the various calibers.

No wonder James Yeager finds high pressure caliber Plastik pistols wear way faster out than 45 acp or 9mm Luger pistols.

I give up on pointing out the difference to you between the gas pressure inside a cartridge, which is what is typically thought of when you mention pressure in relation to cartridges, and the force exerted on the slide. Either you don't get it or don't care, even though I think it really does matter in terms of understanding the mistake in what Yeager was saying.

I would ask that you stop using the word of a man not incredibly well regarded by the firearms community as a definitive voice on firearms design. While he has practical experience, he has no engineering background whatsoever.

If you want 40 S&W caliber guns please double the thickness of the rails, slide, Barrel and any locking mechanism upto about doubling the weight and you should be fine. Same applies for 357 SIG and 10mm. An high pressure pistol should weight about 40 oz and no less.

While that's certainly a way to be "safe", the existence of pistols in these calibers over decades now seems to indicate that your caution might be a bit overstated.

I do think this stray pony that wandered into this thread has been thoroughly beaten into the ground.

TheGuyOfSouthamerica

Moderator

Exactly johnksa

That is what i mean. Slide velocity and other harsh moving parts beating the high pressure caliber pistols to death.

Half life at most.

That is what i mean. Slide velocity and other harsh moving parts beating the high pressure caliber pistols to death.

Half life at most.

Slide velocity and other harsh moving parts beating the high pressure caliber pistols to death.

Half life at most.

Wow I guess I missed the part where he said they were beating themselves to death and had a half life at most.