Chapter Two:

.475" bullets:

Theory: .45 Auto cases should make great .475" bullets when redneck-swaged in an appropriate die.

Reality: Very few dies have the correct dimensions. Only 6.5-284 Norma is in current production and suitable for the cartridge when combined with a Lee bullet sizing die "pusher".

Last week, I FINALLY found a 6.5-284 Norma sizing die for a decent price. I've been looking for quite a while. On clearance at Midway, I actually had a choice between Forster and Redding sizing dies for $25 and $23 respectively. I went with the Redding for the steel lock ring and larger fillet at the die mouth.

Which brings us to the proof of concept. It's a win.

There are some adjustments to be made, and I need to fine-tune case length and core dimensions, but it's viable.

To expand the cases to accept a .475" Lee "pusher", I chopped a Lee .500 S&W expander die that had already been fitted with a .480 Ruger expander. About 3/8" was removed, in order to get the expander within reach of the .45 Auto case. (The .500 S&W 3-die set was purchased used last year, and

dirt cheap, since the shop owner didn't even know he had it.)

Somewhere, a .500 S&W owner is screaming at his computer screen:

Side note: This is one of the reasons why I hate Lee dies for serious reloading tasks. They aren't even hardened. I chewed through this die in about 45 seconds ... with an old blade.

Shortly thereafter, I discovered that the minimum body taper design of the 6.5-284 Norma meant that a .475" pusher won't fit in the die once there's a .45 Auto case wrapped around it. I couldn't find my .458" pusher. So, I had to go to one of the .44 caliber pushers. It wouldn't be suitable for production use, because excess lead bleeds around the edge, but it's good enough for proof of concept.

I grabbed some scrap lead wire from setting up my home-built core cutter last year, found a piece around 250 grains - which is was just a rough estimate that I came up with based on experience with the .430" .40 S&W bullets - and crammed it into the die.

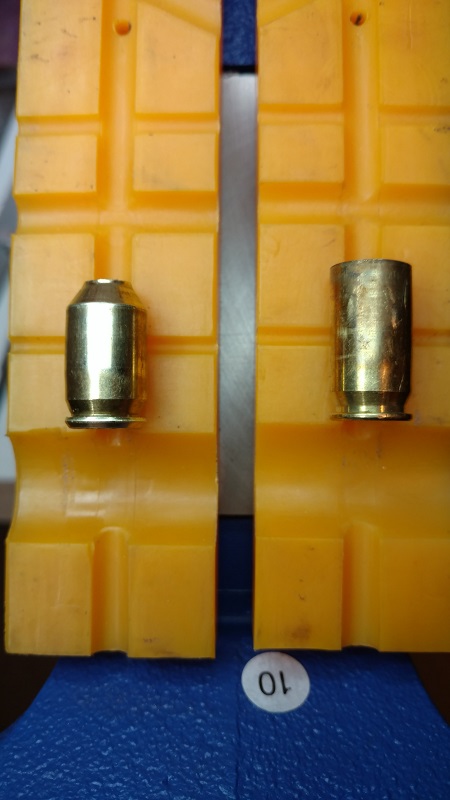

A few smacks of the under-sized ejector gave me a win. The nose was over-inserted into the die, but that's one of the things that'll be fine-tuned later on:

It looks like somewhere around 350 gr will be a good weight for untrimmed cases:

(The uneven lead in the nose was caused by the undersized .44 caliber "pusher" allowing lead to bleed around the edge, and made worse by the undersized ejector punch.)

And sizing, fresh from the die, is about as good as it gets:

(And a trip through a .475 bullet sizer will squeeze the middle down with almost zero effort, if it's needed.)

(The ".477" reference mark is actually 0.4766".)

Tools to track down to do this right:

-My .458" Lee bullet sizing kit, for the pusher. Or, order a .452" sizing kit.

-An appropriately sized section of drill rod for ejecting the bullets from the die. Right now, everything is just slightly oversized, or significantly undersized.

-Something I'm forgetting.

The only remaining test:

Will they feed in an AR-15?

...Stay tuned to find out.