You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Smith & Wesson reintroduces the Model 66

- Thread starter jglsprings

- Start date

Deaf Smith

New member

The changes are made to make it cost less but the price will be higher.

Just FYI.

Deaf

Just FYI.

Deaf

I'll answer in order here...

The re-design had to be done to allow the 2-piece barrel and frame-mounted firing pin. If you examine the parts, the barrel shroud has locating lugs that fit into recesses in the frame (from photos I've seen of a disassembled 620).

Is the 2-piece "better"? The new 66-7 shoots as accurately as any other snubby K-frame I've owned (10, 15, 19) and should perhaps do even better in a longer barrel because a tensioned barrel should not have any induced harmonics.

Define "functional differences"... they operate the same as the old models. The firing pin was moved to be frame mounted. My old K-Frame HKS and Safariland speedloaders still work fine. Internally they've probably made some changes but I've not removed the sideplate to see.

Because the barrel tube screws into the frame opening and it's thinner than the 1-piece barrel, there is more room on the frame below the forcing cone area.

If you speak of manufacturing costs will be less, that's probably true. There is constant pressure to reduce the cost of good and cost of manufacturing to remain competitive and affordable. The use of MIM parts is not new, nor is it detrimental -- Colt used an early version by using sintered powdered metal parts in the Trooper Mk III and later the King Cobra. Countersunk chambers were found to be unnecessary with the reliability of modern ammunition.

The barrel change addresses a weakness in the original K-Frame design (which was designed for a 17,000 psi .38 Special) when it was made to fire the .357 magnum. The frame changes incorporate modifications for a frame-mounted firing pin (which reduces chances of breaking the "hammer nose" used on older S&W's) and locator recesses for the barrel shroud. The topstrap was beefed up a little too.

None of those changes are free. I have no idea how many engineering man-hours were devoted to the redesign, prototyping and testing, much less internal documentation, drawings, specification, etc. ad nauseum.

Keep in mind that I measured the frame differences back in 2004 so I don't have the exact dimensional differences. IIRC (and I can try to confirm this numerically, later, if people want the info) the topstrap is slightly thicker, the frame is slightly longer from frame barrel opening to the rear sight too.jglsprings said:Are the frame dimensions of your model 66 just that much bigger to allow no cut on the forcing cone or are they the same as your Model 19?

Or, do you think new design is a result of the two piece barrel assembly?

On another forum they were discussing the two piece barrel assembly as a better solution for the L frame Model 69 44 mag pistol that was just introduced.

The re-design had to be done to allow the 2-piece barrel and frame-mounted firing pin. If you examine the parts, the barrel shroud has locating lugs that fit into recesses in the frame (from photos I've seen of a disassembled 620).

Is the 2-piece "better"? The new 66-7 shoots as accurately as any other snubby K-frame I've owned (10, 15, 19) and should perhaps do even better in a longer barrel because a tensioned barrel should not have any induced harmonics.

gav1230 said:Besides the lock, is there any functional difference between the new and old ones? Most of the changes like MIM parts seem more like minor aesthetic differences.

Define "functional differences"... they operate the same as the old models. The firing pin was moved to be frame mounted. My old K-Frame HKS and Safariland speedloaders still work fine. Internally they've probably made some changes but I've not removed the sideplate to see.

Absolutely correct.Tom Servo said:Bill, are you saying your 66 does not have the flat spot at the bottom of the forcing cone?

Because the barrel tube screws into the frame opening and it's thinner than the 1-piece barrel, there is more room on the frame below the forcing cone area.

Deaf Smith said:The changes are made to make it cost less but the price will be higher.

If you speak of manufacturing costs will be less, that's probably true. There is constant pressure to reduce the cost of good and cost of manufacturing to remain competitive and affordable. The use of MIM parts is not new, nor is it detrimental -- Colt used an early version by using sintered powdered metal parts in the Trooper Mk III and later the King Cobra. Countersunk chambers were found to be unnecessary with the reliability of modern ammunition.

The barrel change addresses a weakness in the original K-Frame design (which was designed for a 17,000 psi .38 Special) when it was made to fire the .357 magnum. The frame changes incorporate modifications for a frame-mounted firing pin (which reduces chances of breaking the "hammer nose" used on older S&W's) and locator recesses for the barrel shroud. The topstrap was beefed up a little too.

None of those changes are free. I have no idea how many engineering man-hours were devoted to the redesign, prototyping and testing, much less internal documentation, drawings, specification, etc. ad nauseum.

Deaf Smith

New member

None of those changes are free. I have no idea how many engineering man-hours were devoted to the redesign, prototyping and testing, much less internal documentation, drawings, specification, etc. ad nauseum.

Hence the price will be higher.

So how about just making it the OLD WAY but with stronger steel?

Deaf

I got confirmation from a guy who's seen the new ones, and they're like that as well.Because the barrel tube screws into the frame opening and it's thinner than the 1-piece barrel, there is more room on the frame below the forcing cone area.

Funny thing, I never looked closely at the 2004 run, so I never noticed the change.

Deaf Smith said:So how about just making it the OLD WAY but with stronger steel?

Then the price would be higher.

Seriously, I don't know how much more cost it would add to improve on 4140[¹] stainless steel. I do know that some other grades of stainless (e.g. 4340) create their own problems with forging, heat treating and machining.

vrichard

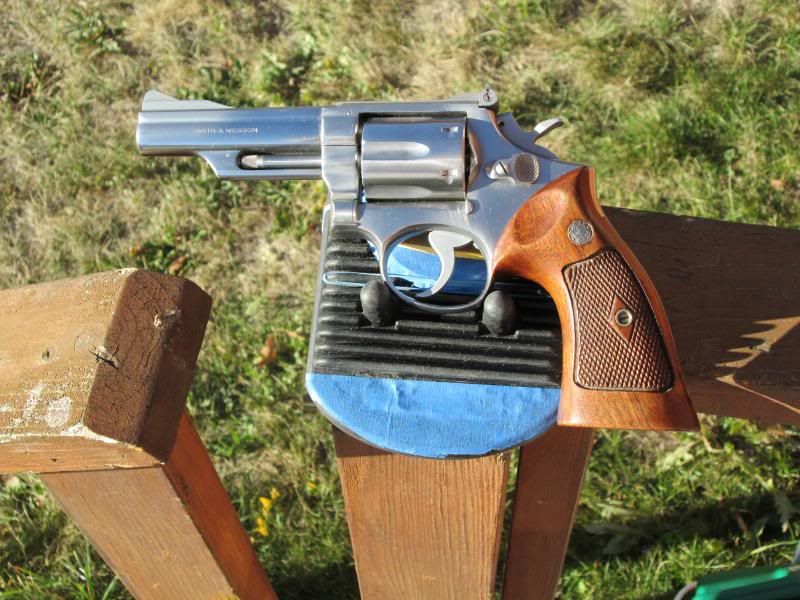

That's a fine looking early Model 66 no-dash you have.

Using vrichard's photo as a comparison, the cosmetic differences you'd see would be;

- New style (MIM) angled cylinder release

- New dark (MIM) trigger & hammer

- Integrated cylinder stop lug (the bump or lug aft of the cylinder opening in the frame. It's press-fit in and ground down in older models)

- Straight angled cut on front of barrel under-lug

- New trigger guard shape

- Slight change (buttressing) to the yoke pivot area on the frame.

- Pinned black front sight w/red ramp.

- Black rear sight

- Non-pinned barrel

- The dreaded Hillary hole (storage lock)

- The angle of the frame's hammer cut is straighter (older ones are a decreasing radius near the topstrap).

Model 66-7 profile photo

Notice the hammer cut is less "scalloped" than vrichard's no-dash model. I believe that's due to the use of the frame mounted firing pin.

Of course, roll marks and lettering will be different due to time.

¹ Last I recall, the 6-series stainless guns were all 4140 stainless.

FoghornLeghorn

New member

My option wasn't in the poll. I don't have any immediate plans to buy one because I already have two. One is a 66 no dash with four inch barrel and a 66-1 with a 2 1/2 inch barrel. Or maybe it's the other way around. I'd have to go look.

Anyway, I don't have any immediate plans to buy one, but that doesn't mean I'll never buy one. I don't carry either of my 66s simply because in their condition, they are "collector" status. But if I had the urge to carry a 66, I'd have no problem with one of the new ones. For example, scratching it up, dropping it on concrete, being under fire by a horde of zombies and my partner is out of ammo and I need to slide the gun across the blacktop in order to get him a gun, that kind of stuff. I'd have no problem abusing a new 66.

But if I were carrying one of the 66s already in my collection, that's different. If I'm under fire from zombies and my partner needs a gun and the only spare I've got is my 2 1/2 inch barrelled 66 P&R, and the only way to get it to him is to slide it across the blacktop? Sorry brother, you're on your own.

Yeah, I could see a condition where I might buy a new 66.

Anyway, I don't have any immediate plans to buy one, but that doesn't mean I'll never buy one. I don't carry either of my 66s simply because in their condition, they are "collector" status. But if I had the urge to carry a 66, I'd have no problem with one of the new ones. For example, scratching it up, dropping it on concrete, being under fire by a horde of zombies and my partner is out of ammo and I need to slide the gun across the blacktop in order to get him a gun, that kind of stuff. I'd have no problem abusing a new 66.

But if I were carrying one of the 66s already in my collection, that's different. If I'm under fire from zombies and my partner needs a gun and the only spare I've got is my 2 1/2 inch barrelled 66 P&R, and the only way to get it to him is to slide it across the blacktop? Sorry brother, you're on your own.

Yeah, I could see a condition where I might buy a new 66.

If I were in the market for a 4-ish" stainless K-Frame, then yes I'd be interested. However, for a 4" or longer barrel I really prefer the larger N-Frames.

As for the changes, the lock isn't really a big deal to me for reasons that I've explained at great length before and really don't care to go into again right now. The two-piece barrel is a non-issue for me either as the two-piece barrel gun that I've shot before (recent production M64) shoots like a laser beam. Actually, I can see an advantage to the two-piece barrel system that hasn't been directly mentioned. Because setting of the barrel-to-cylinder gap and alignment of the sights is separated into two separate steps, it seems to me that one would be less likely to get a revolver with canted sights if said specimen has a two-piece barrel.

I really don't see the ball-detent lockup being a way of "cheaping out" either since most of the guns that I've previously seen with that feature have been Performance Center guns. My understanding is that the point of the ball-detent lockup is to eliminate the need for a locking point at the front of the ejector rod thus allowing a full-length rod on guns with barrels shorter than 3". This suggests to me that perhaps S&W is contemplating a snubby version of the M66 for future production which I may be more interested in.

Finally, as to the price, revolvers are quite simply expensive guns to make. That being said, the new M66 is priced about the same a a 686 which, in my area, will usually go for $700-750 actual retail so I'd expect a new M66 to cost about the same. Considering that a nice used K-Frame Magnum or new Ruger GP100 usually go for $600 or more in my area, I don't really think that a $100-150 premium for a new K-Frame Magnum is all that outrageous.

Now, what I would be very interested in would be a reintroduction of the M19. I've always admired the look of a blued M19 and a new-production specimen, complete with factory warranty, would allow me to have a classy-looking revolver without the guilt associated with routinely carrying a collectible. What would also greatly interest me would be a reintroduction of the M13 and/or M65 as I've grown to appreciate the utility of fixed sights on a working revolver.

As for the changes, the lock isn't really a big deal to me for reasons that I've explained at great length before and really don't care to go into again right now. The two-piece barrel is a non-issue for me either as the two-piece barrel gun that I've shot before (recent production M64) shoots like a laser beam. Actually, I can see an advantage to the two-piece barrel system that hasn't been directly mentioned. Because setting of the barrel-to-cylinder gap and alignment of the sights is separated into two separate steps, it seems to me that one would be less likely to get a revolver with canted sights if said specimen has a two-piece barrel.

I really don't see the ball-detent lockup being a way of "cheaping out" either since most of the guns that I've previously seen with that feature have been Performance Center guns. My understanding is that the point of the ball-detent lockup is to eliminate the need for a locking point at the front of the ejector rod thus allowing a full-length rod on guns with barrels shorter than 3". This suggests to me that perhaps S&W is contemplating a snubby version of the M66 for future production which I may be more interested in.

Finally, as to the price, revolvers are quite simply expensive guns to make. That being said, the new M66 is priced about the same a a 686 which, in my area, will usually go for $700-750 actual retail so I'd expect a new M66 to cost about the same. Considering that a nice used K-Frame Magnum or new Ruger GP100 usually go for $600 or more in my area, I don't really think that a $100-150 premium for a new K-Frame Magnum is all that outrageous.

Now, what I would be very interested in would be a reintroduction of the M19. I've always admired the look of a blued M19 and a new-production specimen, complete with factory warranty, would allow me to have a classy-looking revolver without the guilt associated with routinely carrying a collectible. What would also greatly interest me would be a reintroduction of the M13 and/or M65 as I've grown to appreciate the utility of fixed sights on a working revolver.

Last edited:

The 2-piece barrel is an improvement over the replaced crush system. However some of the crush fits shot well but it was luck of the draw as the torque could have varied a lot; some were good and some not so much. I know my X-frame can shoot groups @ 100 yards that were good for a lot of crush barrels @ 25. The lock is a negative, never cared for them. S&W should have done what everyone else did when the law changed, throw in a cable lock that would never be used and call it done. If I was looking for a small frame 357 I would be okay with a new one but a solid used one being cheaper would be okay as well. Only time will tell to see how well they sell. YMMV

Cosmodragoon

New member

A revolver has to be pretty amazing for me to buy it with a "Hillary Hole". The only one in recent memory was the XVR. This one just doesn't make the cut.

El Paso Joe

New member

Already have one. Bring out a old school nickeled 19 and I might breathe heavy and be hard to control...