You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Smith and Wesson internal lock

- Thread starter ATN082268

- Start date

I can only hope you're right - I didn't read it that way.I think he was being facetious.

ETA: Upon re-reading, and reflection, yup you're right. And a good job of getting me to rise to the bait it was.

Last edited:

Trigger and Hammer are the 2 biggest changes in the 627's..over the 27's...but I don't think its an issue either.

The biggest problem I had ( after I got by the appearance issues on the 627's vs the 27's ) ....is they are all Round Butt N frames ...vs Square Butt on the old N frames. Round Butt doesn't fit my hands very well...at least with the stock grips they provide ( they are wood on both models ) ...but I needed some more "beef" in them, so I went to a S&W Wood grip with finger grooves on the 2 5/8" checkered with 3 finger grooves in it / and a Hogue wood grip with 3 finger grooves on it, for the 5"...checkered also / with palm swells in them.

The biggest problem I had ( after I got by the appearance issues on the 627's vs the 27's ) ....is they are all Round Butt N frames ...vs Square Butt on the old N frames. Round Butt doesn't fit my hands very well...at least with the stock grips they provide ( they are wood on both models ) ...but I needed some more "beef" in them, so I went to a S&W Wood grip with finger grooves on the 2 5/8" checkered with 3 finger grooves in it / and a Hogue wood grip with 3 finger grooves on it, for the 5"...checkered also / with palm swells in them.

I am a little confused by your statement. "Skilled workers", as per definition is a worker who has some specialized training and has a title such as, "Machinist", "Millwright", or "Mechanical Engineer", and in most cases have a title that includes the words: "Journeyman". No such "skilled worker" has ever assembled a product in any factory that I have ever worked in (Whitehall Industries, Ludington MI, Oloffsson Manufaturing, Lansing MI, Ossur Prosthetics, Albion MI), has ever titled an assembler as a skilled worker and paid them as such. Assemblers have, to the best of my knowledge, been considered "unskilled" hourly labor. However, if you have actually worked at Smith & Wesson and have some specific knowledge that I am unaware of, I would like to hear about it.That means the guns can be assembled by workers who do not have the skill level of the assemblers in the past, and that is another way to drive the cost out of producing the guns. You don't have to pay unskilled workers as much as you have to pay skilled workers.

Or have you just made an assumption? Ask'en for a friend.

It is socially and morally reprehensible to NOT desire a lock on Smith revolvers.

While I get the sarcasm, that attitude really exists and is the biggest problem behind the entire lock issue. Some how its become popular thought (especially among non gun owners) that if you don't lock a gun, you aren't safe. And that (somehow??) you are putting all of us at risk, if you don't use a lock ON or IN a gun.

Unloaded guns are not dangerous. And I'm all in favor of locking guns (and ammo) IN something.

The ONLY point to having a loaded gun stored is to ensure the most rapid access practical. Having to FIND THE KEY and USE IT (and where the heck is that dang thing this time????) in a high stress situation seems to go a long way to negate the advantage of having a loaded gun, to my way of thinking.

BlackLabsMatter

New member

I wasn't being facetious.

Key locks and retroactively added safety switches don't mitigate reckless behavior, they enforce them.

Why? Because people relied on them when negligently handling a firearm. Every negligent gun death is preceded by "I thought" and ends in "it just went off". No one's ever at fault, ever. Maybe gun banners are right. Guns just go around killing people on their own.

I could have produced an instant fix that could have been implemented even quicker than a redesign:

You see that ring on the bottom of the frame? It's called a lanyard ring. Properly tied, lanyards prevent drops. The materials for lanyards are available aboard any vessel.

Mishandling of weapons is always dangerous and NO firearm is intended to be dropped. People have shot themselves catching pistols, even when they have firing pin blocks.

Dropping weapons can be lethal even if they don't fire. It becomes a weapon out of your control and at best, momentarily takes you out of the fight, reducing the readiness of your team/platoon. The weapon can get lost, break, fall into hostile hands, or get people killed when you should have been ready.

You want to prevent only the effect while ignoring the cause.

There's a reason it's THE mortal sin in the military to drop a weapon.

Speaking of which, I've seen an NCO's Beretta fail to fire due to a firing pin block failure(the lever that lifted it sheared), rendering it inoperable. It was a combat environment and could've got him killed. "What would you say to his parents" if it did? He never dropped or negligently handled his weapons, but he was a combat soldier, properly trained in a professional Army.

I also can't tell if a key lock is engaged myself, just by looking at it. I see it as dangerous for that reason alone. A cable through a chamber? Absolutely.

We have all sorts of inventions to idiot proof gun mishandling. How about hunter orange? Needed because reckless "hunters" shoot at every sound and movement, turning the woods into war zones every deer season. And yet people, livestock, and houses get shot every year. Maybe we need to paint them orange too.

Or we could have better education and hold people accountable for their actions. Crazy, I know.

Key locks and retroactively added safety switches don't mitigate reckless behavior, they enforce them.

Why? Because people relied on them when negligently handling a firearm. Every negligent gun death is preceded by "I thought" and ends in "it just went off". No one's ever at fault, ever. Maybe gun banners are right. Guns just go around killing people on their own.

I could have produced an instant fix that could have been implemented even quicker than a redesign:

You see that ring on the bottom of the frame? It's called a lanyard ring. Properly tied, lanyards prevent drops. The materials for lanyards are available aboard any vessel.

Mishandling of weapons is always dangerous and NO firearm is intended to be dropped. People have shot themselves catching pistols, even when they have firing pin blocks.

Dropping weapons can be lethal even if they don't fire. It becomes a weapon out of your control and at best, momentarily takes you out of the fight, reducing the readiness of your team/platoon. The weapon can get lost, break, fall into hostile hands, or get people killed when you should have been ready.

You want to prevent only the effect while ignoring the cause.

There's a reason it's THE mortal sin in the military to drop a weapon.

Speaking of which, I've seen an NCO's Beretta fail to fire due to a firing pin block failure(the lever that lifted it sheared), rendering it inoperable. It was a combat environment and could've got him killed. "What would you say to his parents" if it did? He never dropped or negligently handled his weapons, but he was a combat soldier, properly trained in a professional Army.

I also can't tell if a key lock is engaged myself, just by looking at it. I see it as dangerous for that reason alone. A cable through a chamber? Absolutely.

We have all sorts of inventions to idiot proof gun mishandling. How about hunter orange? Needed because reckless "hunters" shoot at every sound and movement, turning the woods into war zones every deer season. And yet people, livestock, and houses get shot every year. Maybe we need to paint them orange too.

Or we could have better education and hold people accountable for their actions. Crazy, I know.

Driftwood Johnson

New member

I am a little confused by your statement. "Skilled workers", as per definition is a worker who has some specialized training and has a title such as, "Machinist", "Millwright", or "Mechanical Engineer", and in most cases have a title that includes the words: "Journeyman". No such "skilled worker" has ever assembled a product in any factory that I have ever worked in (Whitehall Industries, Ludington MI, Oloffsson Manufaturing, Lansing MI, Ossur Prosthetics, Albion MI), has ever titled an assembler as a skilled worker and paid them as such. Assemblers have, to the best of my knowledge, been considered "unskilled" hourly labor. However, if you have actually worked at Smith & Wesson and have some specific knowledge that I am unaware of, I would like to hear about it.

Or have you just made an assumption? Ask'en for a friend.

No, I have never worked for Smith and Wesson. Maybe I made a bit of an assumption.

I worked in various manufacturing companies for a long time, and it was always clear to me that workers who had worked longer, and also had attained higher skill levels than other workers, were paid better than workers with lower skill levels. Job titles were usually something like Assembler 1, or Assembler 2, Assembler 3, or something along that line.

I also know that the way S&W revolvers used to be assembled in their heyday, it was a more labor intensive process than it is today, and trimming extra labor out is a good way for a company to drive down their cost of manufacturing.

I spent a number of years as a mechanical designer and know clever part designs when I see them.

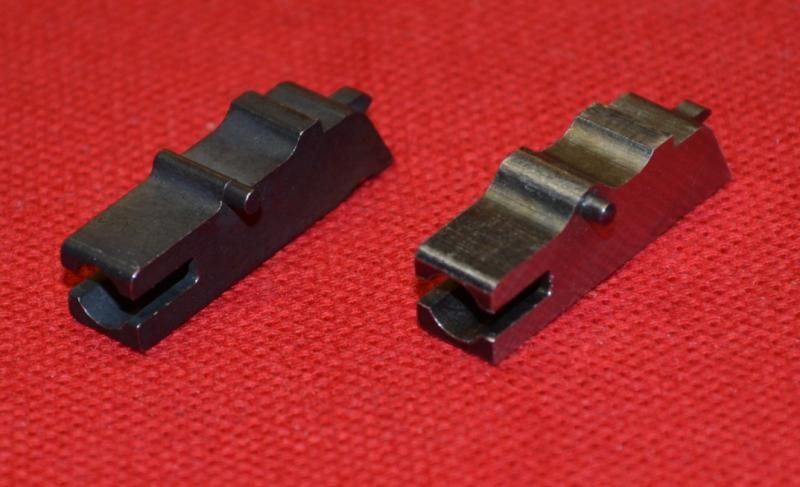

Let's compare the hammer assembly in a typical S&W revolver made before and after MIM (Metal Injection Molding) technology came along. In the following two photos, the hammer assembly on the left is from a Model 17-3, made in 1975, the MIM hammer assembly on the right is from a Model 617-6, made in 2003. These are analogous assemblies, both are from K frame 22 Rimfire revolvers.

The first thing that strikes me about the two assemblies is the traditional one is held together by press fit pins, the MIM assembly is not pinned together, the parts are held together by their geometry, without requiring pins to hold them together. Pinning parts together requires a little bit more talent and skill than simply assembling them on the bench. To assemble the parts with pins, the worker needs to know how to drive in press fit pins. Not rocket science, but assembling parts that 'drop in' on the bench without extra tools is simpler and quicker than assembling parts held together with press fit pins. As we all know, time is money.

In any company I ever worked for, you needed to inventory parts. If parts went together as subassemblies, you also needed to inventory those subassemblies. When you kitted up parts for assembly, subassemblies would be kitted rather than the individual parts needed to make the subassembly. It appears to me that the parts for the MIM hammer assembly could be taken directly from their parts bins and assembled while the revolver is being built, no pre-building of a subassembly is necessary, another cost savings for the company. No subassembly to inventory and take up space in the storeroom.

The double action sear in the MIM assembly (the part protruding from the front of the hammer) is able to rotate to do its job because of its geometry and the geometry of the section of the hammer that houses it. It does its job of rotating without needing a pin to keep it centered, and it can be dropped into place after compressing the spring. That is a very clever part.

What about all those pockets on the part? The curved geometry at the top of the part is what actuates the flag on the internal lock to activate and inactivate the lock. The other pockets are simply to reduce the amount of material needed to make the part, another cost savings. Part of the beauty or MIM technology is it is very similar to the injection molding process used to make plastic parts. Complex geometries can be machined into the molds for the parts, much cheaper than machining similar geometries onto parts with traditional methods.

Let's look at a much simpler part, the rebound slide. This time the MIM part is on the left, the traditional part is on the right. The pin protruding from the traditional part is what activates the modern hammer block. The pin is a separate part, pressed into a hole in the body of the rebound slide. The MIM part is all one piece, after it pops out of the mold and goes through the necessary curing it is complete, no further operations are required. The traditional part requires multiple machining steps to complete its shape.

So, you might ask why after singing the praises of MIM technology I prefer the old fashioned way of making S&W revolvers. MIM technology has advanced so far that most of the parts are ready to be assembled without custom fitting. In 'the old days', parts were 'soft fitted' together before hardening and final assembly. This was extremely labor intensive and added to the cost of making the revolver. However, in my humble opinion, the trigger pull of a revolver assembled with MIM technology cannot duplicate the smoothness of the trigger pull of parts that have been hand fitted. That is why I prefer the old guns.

And let's not forget, all that time saved with clever design means it takes less time to make a revolver than it did in the old days, and that means fewer workers are required. We will never go back to the 'good old days' of manufacturing, and I am not saying we should, but I am guessing that there are fewer manufacturing jobs in most factories today, because of the advance of technologies such as Metal Injection Molding.

Last edited:

This has been an eye-opening discussion. I don't think I'm going to be too concerned about MIM parts in products from S&W. Part of me likes the more complex geometry of the MIM part which eliminates things like pinning parts together. On the other hand, with that side-by-side comparison I can visualize it could be more difficult to smooth out the action.

I would love to see photos like that of the internal lockwork for the 8-shot 627 I've been oogling over. I wonder if the performance center guns are different in that regard?

I would love to see photos like that of the internal lockwork for the 8-shot 627 I've been oogling over. I wonder if the performance center guns are different in that regard?

Driftwood Johnson

New member

I would love to see photos like that of the internal lockwork for the 8-shot 627 I've been oogling over. I wonder if the performance center guns are different in that regard?

Well, I ain't going to be me that does such a photo spread, I doubt if I will be buying any more modern Smiths. I already have a Model 27 and three Model 28s, and unless a 627 were to drop into my lap at a ridiculous price I don't anticipate buying one.

Did you check out the link I provided to the photo essay I did a few years ago at The High Road? I suspect that your oogled 627 will be very similar inside to the 617 I dissected.

Just for fun, here is a photo of a 686 I bought a couple of years ago. This is built on the L frame, not the N frame like the 627. But you can see a lot of the parts in this view. This is the first brand-spanky new S&W revolver I bought in about 40 years. I only bought this gun because I did not own any L frame Smiths. I took the side plate off because I wanted to see the lockwork, but I have not detail stripped it because it was a brand new gun when I bought it. Maybe when I have nothing to do I will rip it apart and photo all the parts.

Did you check out the link I provided to the photo essay I did a few years ago at The High Road?

I found it and will read. Thanks.

Here is a New S&W M&P 340 with NO LOCK !! And it is mine, all mine ........

That is very interesting. For extra money S&W will offer a revolver without a lock. Apparently S&W knows the buyers dont like the lock, and still build 99% of the guns with a lock. And for this one model without, they charge a premium for less machining and less parts. This cannot be good public relations. I just purchased a new S&W and assumed the lock was on all revolvers and was for ever moving forward.

ok, if this is the game, I can wait.

Now all the complaints, I did not get it. Sure it may not be not as big a deal as many make it out. But what the heck, you are the customers and have a right to speak up for what you want.

springer99

New member

Actually, I haven't seen any difference in price for those models that S&W offers without the lock. Not at my dealers, at least.

To be honest, S&W should charge more for the units without the lock, simply because it requires them to manage separate manufacturing and QC/QA processes. That they don't charge a premium, I say good for them.

To be honest, S&W should charge more for the units without the lock, simply because it requires them to manage separate manufacturing and QC/QA processes. That they don't charge a premium, I say good for them.

North East Redneck

New member

I own, shoot and carry a 442 with the lock. This gun has several thousand rounds through it. I have had zero issues with this revolver. Locked it up with some poorly seated primers when I reloaded with a Lee Classic, not the guns fault.

I know a realitive that purchased a 442 last year, new gun from dealer, no lock and price was about the same as I paid 5-7 years ago.

I don't like the lock on principle, but it doesn't worry me at all.

I know a realitive that purchased a 442 last year, new gun from dealer, no lock and price was about the same as I paid 5-7 years ago.

I don't like the lock on principle, but it doesn't worry me at all.

Actually, I haven't seen any difference in price for those models that S&W offers without the lock. Not at my dealers, at least.

That is good. I must have compared different versions.

The lock does not bother me much. A little ugly and more small pieces we dont need. I dont plan to ever lock it. It seems most customers would prefer not to have the lock. Now it even hurts resale. What the heck is wrong with S&W? If they can build one without a lock they can do them all or more. Not enough competition, I guess.

Ruger Mark III had a miserable chamber indicator that was another unattractive feature and on margin, a liability. It required more cleaning. And on a rare out of chamber discharge could be a hazard. Bottom line, good or bad, the customers either did not like it or just grin and bare it. Along came the S&W Liberty and what the heck!! A new Mk IV no plastic loaded indicator and surprise, surprise easy take down.

Same problem, both companies, dont listen. They build any piece of bling they can dream up, but meaningful changes are few and far between.

No problem here. Money is tight enough I can pick and choose. I got one locking smith and one MK III. No more of either in my future unless its a give away used price.

"... companies don't listen..."

Not always true; sometimes customer ignorance is a factor. I recently let a pretty knowledgeable gun person shoot my S&W Model 1899. He pointed out that the company made almost no changes (except the "lock") to this day. I used both my guns and Driftwood's great photos to show the dozens of changes S&W had made over more than a century. He had had no idea that the guns had changed so much internally and recognized that almost all the changes had been for the better.

Jim

Not always true; sometimes customer ignorance is a factor. I recently let a pretty knowledgeable gun person shoot my S&W Model 1899. He pointed out that the company made almost no changes (except the "lock") to this day. I used both my guns and Driftwood's great photos to show the dozens of changes S&W had made over more than a century. He had had no idea that the guns had changed so much internally and recognized that almost all the changes had been for the better.

Jim

Another likely reason we still have the lock is that the people who bought S&W from the British holding company WERE the people who INVENTED (designed) the lock in the first place. (or so we heard at the time...)

I would think that they feel their lock is a fine idea, and remember that at the beginning the major objection to the lock was politics, not the actual mechanism itself.

I would think that they feel their lock is a fine idea, and remember that at the beginning the major objection to the lock was politics, not the actual mechanism itself.

The internal lock is not something I would have requested but it doesn't bother me as I have never locked any of them yet nor has any just locked on their own. I went to Smith & Wesson Revolver training and the new MIM parts often just drop in with little more than a polish. The MIM parts can be made of harder, more durable alloy as little machining is required so I understand why Smith uses them. In terms of measurable performance, the new revolvers I have are better than the old ones I own. The new Smiths are great revolvers and I would not hesitate to buy another one.