You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Seating into the lands , Pressures & velocities

- Thread starter Metal god

- Start date

A comparator shows the difference of a property of one thing to a property of another. Size, shape, weight, color, whatever matters for its objectives.Ok you pass bullet nomenclature 101, now define comparator and give and example of how it works

Optical comparators compare shapes.

houddawg said:with a comparator it really does not make a darn if the hole is throat size or not, just as long as it is smaller than the diameter of the bullets bearing surface

If you go back to my post #30, you'll notice the Hornady insert produced a larger bullet base to ogive standard deviation than the Sinclair did. What caused that is that even though bullets have a nominal ogive radius, the ogive radius is often imperfectly uniform on them. As a result, when the caliper insert hole is smaller than an actual barrel throat, it will rest on these varying ogive radii at different distances from the bullet shoulder (where the bearing surface ends and the ogive begins—the part that contacts the throat). Your Sinclair inserts avoid that added variation by being throat-size, so they measure the bullet where the throat will actually make contact with it. But this doesn't fix the fact the seating dies contact the shoulder a way up. What it does do is give you the opportunity to select an insert that contacts the ogive where the seating die does and to sort them by the difference in the dimension from the shoulder to that point.

I've found about 0.002" variation fairly common, but occasionally up to 0.005" on non-match bullets. You also get some lots where there is essentially no practical variation.

It's another in the long list of things to check when rolling super-match loads. If you find the variation, it is something you can separate into two or three identifiable groups pretty easily. You can adjust your seater to make them all the same, though I doubt the few thousandths difference in bullet jump itself makes a detectable precision difference. But if you look at that variation as a clue there is something different about the bullets themselves that made that difference occur, then sorting can, with some lots, break them into a more and less accurate groups.

well Nick if the ogives are inconsistent then they will be inconsistent whether the comparator hole is .025 smaller than the throat or .010 or .001. It's the consistency of the assembled round that counts.

As far as bullet jump distance I have found that as little as .003 difference in jump can make a difference. Using my old Hornady comparators I am now getting groups down into the .3's and .2's (MOA) out to 300 yards and sub .5's out to 800. Not benchrest accuracy but not bad for garage built rifles and a old fart shooting them that took up precision shooting about 10 years ago

As far as bullet jump distance I have found that as little as .003 difference in jump can make a difference. Using my old Hornady comparators I am now getting groups down into the .3's and .2's (MOA) out to 300 yards and sub .5's out to 800. Not benchrest accuracy but not bad for garage built rifles and a old fart shooting them that took up precision shooting about 10 years ago

What's the size of the biggest groups with the same ammo that shot in the 2s, 3s and 5s at their respective ranges?As far as bullet jump distance I have found that as little as .003 difference in jump can make a difference. Using my old Hornady comparators I am now getting groups down into the .3's and .2's (MOA) out to 300 yards and sub .5's out to 800.

I found it interesting that my Sinclair insert gave me a .001 larger ES closer to the bullet diameter then my Hornady insert did a little bit further up the ogive . Can they both be right ? I was thinking that one must be measuring incorrectly but the more I think about it they both could actually be giving correct measurements .

Metal both are right. You are comparing, not measuring.

example - my Hornady inserts measuring a loaded 105 grain Hornady in a 6BR case

.20 insert = 1.979

.22 insert = 1.891

.24 insert = 1.873

as long as I use the same insert for both the initial distance to lands using the OAL and setting my seating depth the rounds will all be the same distance to the lands allowing for whatever ogive discrepancies that are present in the manufacture of the bullets

You could have 2 comparator inserts from the same manufacturer but different lot numbers that would be slightly different if the tooling was changed. Your distance to the lands also constantly changes as throat erosion causes changes in the throats diameter and rifling gets as metal gets ate away with every round fired

example - my Hornady inserts measuring a loaded 105 grain Hornady in a 6BR case

.20 insert = 1.979

.22 insert = 1.891

.24 insert = 1.873

as long as I use the same insert for both the initial distance to lands using the OAL and setting my seating depth the rounds will all be the same distance to the lands allowing for whatever ogive discrepancies that are present in the manufacture of the bullets

You could have 2 comparator inserts from the same manufacturer but different lot numbers that would be slightly different if the tooling was changed. Your distance to the lands also constantly changes as throat erosion causes changes in the throats diameter and rifling gets as metal gets ate away with every round fired

No not comparing , one insert had a ES of .001 with 30 measured , the other insert had a ES of .002 measuring the same cartridges . I did not compare anything because the contact points were in different areas of the ogive . The only thing that was compared were the results . Which considering how close those two contact points are I'd think I would have got the same ES with both inserts . In theory the Sinclair insert is saying the closer I got to the full diameter of the bullet the less consistent the construction was . I would have expected the opposite .

Here's a link to a good diagram showing how bullet diameter on the ogive changes per tenth inch of base to ogive dimension. Very little the first tenth past bullet .308" diameter where the ogive starts. Very much several tenths further down the ogive.

https://www.google.com/search?clien...81379399&biw=911&bih=683#imgrc=zjHJ-Wf9kmnzXM

Easily calculated using trigonometry formulas.

https://www.google.com/search?clien...81379399&biw=911&bih=683#imgrc=zjHJ-Wf9kmnzXM

Easily calculated using trigonometry formulas.

Last edited:

No not comparing , one insert had a ES of .001 with 30 measured , the other insert had a ES of .002 measuring the same cartridges

my bad I misread your earlier post. To me that just tells me the bullets ogives are not as consistent as they could be

here is a good read on comparators and BTO measuring by Berger bullets

https://bergerbullets.com/effects-o...coal-and-cartridge-base-to-ogive-cbto-part-2/

a quote from the article, underlining added by me

To measure from the base of the cartridge to where the bearing surface ends on the bullet you must use a gauge that will attach to your calipers and which also goes over the nose of the bullet to touch the point where the bearing surface transitions into the nose curve. We already sorted out that bullets can and will vary in this area (at least from type to type if not lot to lot).

Last edited:

The cartridge base (case head?) is not the control point because it's not against the bolt face when the round fires. Like Unclenick stated, it's the case shoulder because it's against the chamber shoulder when the round fires. Cartridge base is X thousandths off the bolt face when rounds fire. Often before triggers are pulled they're pushed there by ejectors.

The cartridge base (case head?) is not the control point because it's not against the bolt face when the round fires.

True but I use a modified case that just happens to be the same size head to datum as my sized cases . This should mean when I got my initial max COAL measurement to the lands using the modified case . That measurement "should" be the same as my sized and loaded cartridges comparatively correct when headspacing off the shoulder ?

I've pointed out several times over the years that using the comp shell holders result in having incredibly consistent case headspace I'm confident that my initial max COAL to the lands translates very close to what I get with my loaded rounds when fired . Remember to get that measurement you are manually pushing the case up against the chamber shoulder then pushing the bullet into the throat . Meaning the case is actually in it's initial firing position when getting that measurement . ad in by chance my modified case is the same size as my resized cases and I should get the correct numbers for my combination of components and rifle .

Bearing surface on bullets goes from the barrel's bore diameter on their ogive back to that diameter on their base or tapered heel. Even if the barrel groove diameter is larger than bullet diameter which happens frequently.

https://www.google.com/search?sxsrf...biw=911&bih=683&dpr=2.25#imgrc=cX4oYgMwsTHqHM

Note the right hand bullet first pictured. Look closely and see the grooves made by the lands extend forward past bullet diameter on the ogive and rearward past bullet diameter on its heel.

https://www.google.com/search?sxsrf...biw=911&bih=683&dpr=2.25#imgrc=cX4oYgMwsTHqHM

Note the right hand bullet first pictured. Look closely and see the grooves made by the lands extend forward past bullet diameter on the ogive and rearward past bullet diameter on its heel.

Last edited:

Only if your full length sized cases have the same head to shoulder dimension as chamber headspace. I think. Unless I misunderstood.True but I use a modified case that just happens to be the same size head to datum as my sized cases . This should mean when I got my initial max COAL measurement to the lands using the modified case . That measurement "should" be the same as my sized and loaded cartridges comparatively correct when headspacing off the shoulder ?

Last edited:

Bart , no the modified case I use headspaces on the chambers shoulder when making the initial measurement. It just so happens that the modified case I use is also the same size head to datum as the cases I actually fire in the rifle .

This means the measurement I get from my modified case should be exactly the same measurement I’m producing when I load my cases . Sorry , I know what I mean I’m just having problems describing it .

This means the measurement I get from my modified case should be exactly the same measurement I’m producing when I load my cases . Sorry , I know what I mean I’m just having problems describing it .

Last edited:

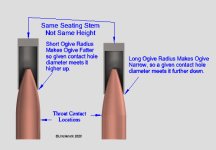

I decided to illustrate the principle with exaggeration so the effect of ogive variation can be seen. You can see from the illustration that a smaller-than-throat hole contacts the different size ogives at different heights. This is true whether the smaller hole is in a seating stem ram as shown, or if it is a comparator insert. An actual throat profile, though, will contact the bullet where it actually meets the lands and this eliminates and ogive variation causing an error in the measurement.

The practical problem stems (cough! cough!) from the seating ram being in the same location from the case when seating both bullets. It results in ogive error at the seating stem's contact point being added to or subtracted from bullet jump, depending on which direction the ogive irregularity was in. You can see the bullet bases and throat contact points being offset as a result of this.

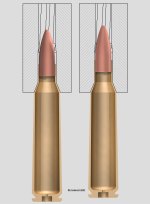

Then there is the problem of uneven case shoulder difference in resizing on rimless bottleneck cartridges. Since the case shoulders stop the case going forward, if one shoulder is a couple of thousandths shorter than the next, even if the bullets were absolutely identical, the bullet loaded into that case will have that couple of thousandths less jump, since it sticks that much further into the throat when the case shoulder hits the chamber shoulder. Below the bullets are identical and the case lengths identical and they are seated with the same seating die setup, yet, because the second case's shoulder "setback" is greater, the bullet jump upon firing is less.

The only way I know to KNOW your bullet jump is the same is to measure the case shoulder location and the bullet's actual contact point with the chamber throat and make sure the comparative difference is the same.

The practical problem stems (cough! cough!) from the seating ram being in the same location from the case when seating both bullets. It results in ogive error at the seating stem's contact point being added to or subtracted from bullet jump, depending on which direction the ogive irregularity was in. You can see the bullet bases and throat contact points being offset as a result of this.

Then there is the problem of uneven case shoulder difference in resizing on rimless bottleneck cartridges. Since the case shoulders stop the case going forward, if one shoulder is a couple of thousandths shorter than the next, even if the bullets were absolutely identical, the bullet loaded into that case will have that couple of thousandths less jump, since it sticks that much further into the throat when the case shoulder hits the chamber shoulder. Below the bullets are identical and the case lengths identical and they are seated with the same seating die setup, yet, because the second case's shoulder "setback" is greater, the bullet jump upon firing is less.

The only way I know to KNOW your bullet jump is the same is to measure the case shoulder location and the bullet's actual contact point with the chamber throat and make sure the comparative difference is the same.