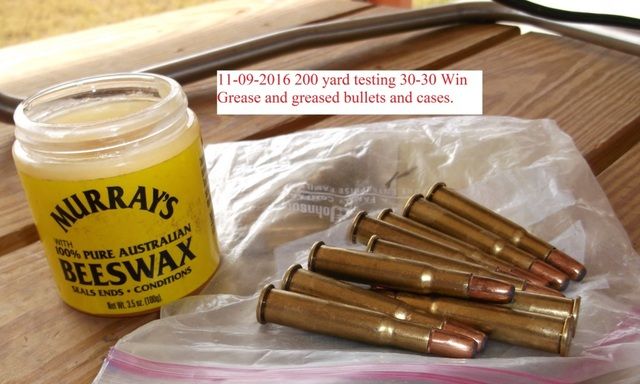

So the thousands of rounds I've fired with case lube residue left on have not destroyed my rifle after all . Thanks for the warm and fuzzy confirmation Slamfire.

I am glad to help. What you have observed, is that your firearms have not been damaged, I am certain you have not observed excessive pressures, traceable to a coating of light lubricant alone. Nullius in verba is the motto of the Royal Society. https://en.wikipedia.org/wiki/Royal_Society It means, on the word of no one. The Royal Society was established in 1660, in a time period when anyone claiming that the scientific writings of the ancient Greeks were in error, was likely to be fined or imprisoned, or burnt at the stake for heresy. Science was based on the authority of these Greeks. These guys had been dead for thousands of years, were doing the best they could at the time, but, in most things, they were wrong. The Royal Society took the position that observations in the real world take precedence over authority. This was just at the beginning of what we call science, which is based on observation and repeatability.

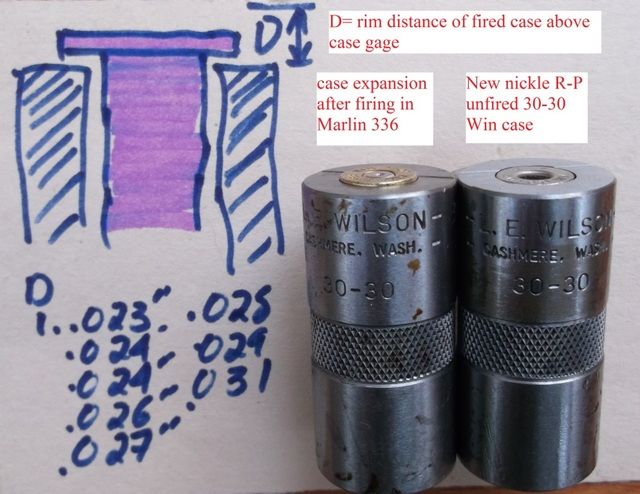

Hatcherism and Ackleyism are authority based systems, and because my observations in the real world do not support them, and they lack repeatability, they must be fallacious.