Anyone got any empirical data on the % increase of bolt thrust from a nominal amount of residual case lube, versus a spotlessly clean case....?

(...and whether it really matters?)

Hatcherites and Ackleyites all start from the basic premise that the action is weak and the case is strong. That is, the purpose of the case is to take load off the action, be a structural member, when in fact, the case is delicate gas seal that needs to be supported by the action.

A series of questions:

1) what loads are actions designed to hold?

2) How much bolt thrust does a case provide?

3) Are actions weakened based on the case removing bolt thrust?

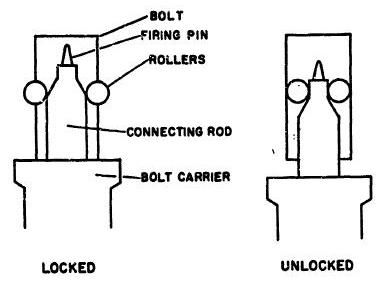

For the first, an action designer assumes that the action absorbs the full thrust of the case and does not assume the case carries any load.

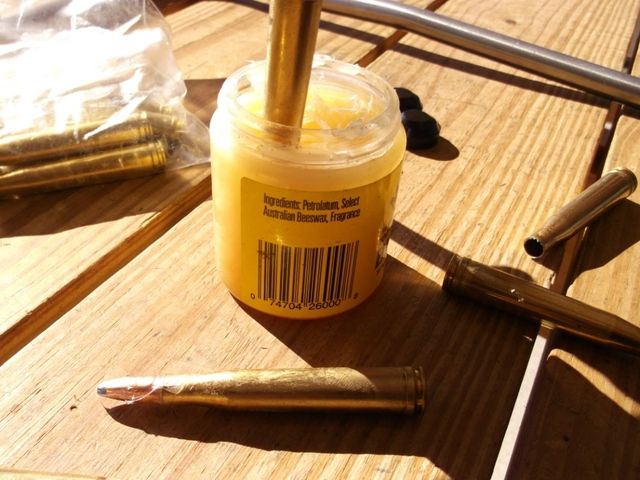

Case to chamber friction does reduce bolt thrust, and it does so by stretching the case, usually permanently stretching the case. However, case friction is not a constant. It varies, it varies a lot. Depends on chamber finish, chamber cleanliness, and whether there is any grease, water, oil in the chamber or case. If you are really worried about bolt thrust due to oily cases, make sure you use a chemical wash to remove all oils, and wear gloves to prevent finger oils from getting on the case sidewalls.

Actions are not weakened assuming the case carries bolt thrust. Only a very stupid person would design an action to hold less than the full thrust of the cartridge. Case thrust on the bolt is calculated as maximum cartridge pressure times case outer diameter. This gives a load in pounds feet. I would calculate case thrust based on the maximum diameter at case head separation. I challenge the Hatcherites and Ackleyites in this forum to state just how much case friction a designer should plan for, in weakening his mechanism? Just how much reduction in bolt thrust comes from case to chamber friction, is it 10%, 20%, 50%, 75%, 100%, and thus, should the action designer weaken his locking lugs by 10%, 20%, 50%, 75%, or 100%? Just what is the number?

For those worried about the increased bolt thrust created by any grease or oil on a case, do you realize by neck sizing, or chambering a zero tolerance cartridge is increasing bolt thrust to the maximum amount? For a mathematic treatment of this I recommend reading Professor Boatright’s papers on this.

Steel Support for the Brass Cartridge Case by James A. Boatright

http://www.thewellguidedbullet.com/pdfs/SteelSupportfortheBrassCartridgeCase.pdf

Yielding of Brass Case Walls in the Chamber by James Boatright

http://www.thewellguidedbullet.com/pdfs/YieldingofBrassCaseWallsintheChamber.pdf

If the math is too difficult, basically what Professor Boatright is telling is unless you are stretching the cartridge case, you are maximizing the bolt thrust. I recently re read his papers, having missed the point earlier, and I totally agree. To reduce bolt thrust by case stretch there has to be clearance between the cartridge shoulder and the chamber shoulder. Of course the case and chamber have to be sticky enough to grab. Chrome chambers would increase the bolt thrust because chrome reduces chamber friction. Oils and greases would reduce friction even more than a chrome coating. With a case shorter than the chamber, the firing pin pushes it forward in the chamber, the primer ignites, and then, the front of the case sticks to the chamber. Then as pressure builds, the case carries load by side wall stretching. The case sidewalls are stretched by the amount of clearance there was at the time of case adherence. Since the case is carrying load, by being stretched, some of that load is removed from the bolt lugs.

Now if you have a crunch fit case, such as what happens with an overlength case, or a neck sized case, while the case will adhere to the chamber, it won’t stretch, thus maximizing the amount of bolt thrust. The thrust has to be equal to the bolt thrust of a fully lubricated cartridge, perhaps more.

There are many who worry about increasing bolt thrust, and they should be made aware that neck sizing increases bolt thrust to the maximum possible amount. Do I think any Hatcherite or Ackleyite will stop neck sizing or warn about the “dangers” of neck sizing, heck no. They live in an inconsistent physical universe, not bounded by what is considered the laws of physics in this universe.

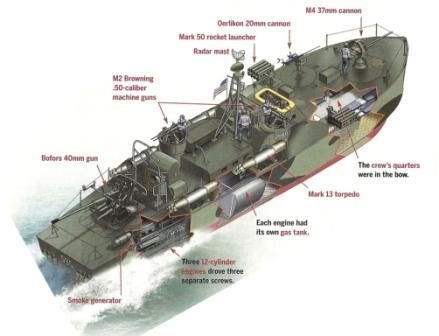

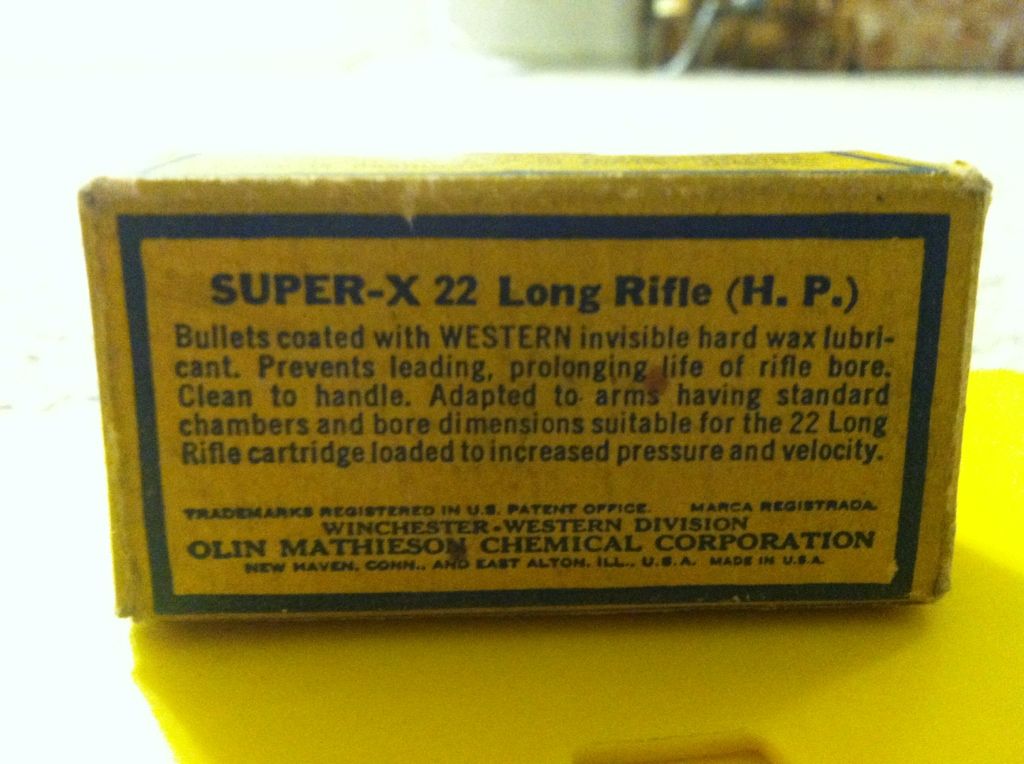

And, for those who warn about the dangers of greased and oiled rounds, just how do you explain the multiple actions that had oilers, and the actions that required greased ammunition, and cartridges that are lubricated with “polymer” coatings? Of course you can’t, you don’t even know of their existence, and you would probably ignore them anyway because they don’t fit into your fantasy physical universe. These polymer coatings are typically a mix of wax, grease, Teflon, all there to break the friction between case and chamber. They are called “polymer” coatings because the industry knows the loud howling that would come from ignorant Hatcherites and Ackleyites if they told these people that there was grease or oil on the cartridge.

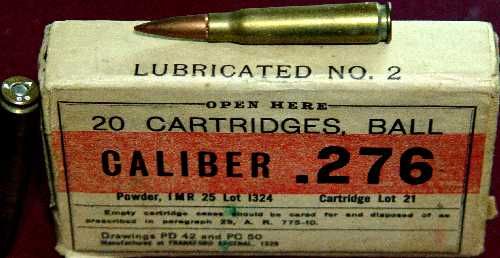

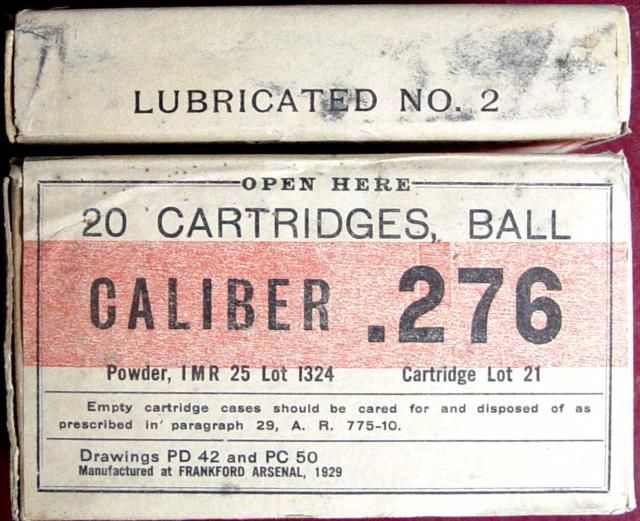

Do you think a designer such a John Pedersen would spend the time, money, effort, patenting a lubricated case process if it was dangerous? He knows that in fact, breaking the friction between case and chamber is good for the case, and good for gun function.

http://www.google.com/patents/US1780566

Patented Nov. 4, 1930 PATENT OFFICE JOHN DOUGLAS PEDERSEN, OF SPRINGFIELD, MASSACHUSETTS 11,0 Drawing.

This invention relates to a process for coating cartridges and more particularly the affixing of a coating of hard wax to the metal case of a cartridge; and the object of the invention is to provide a method whereby cartridges may be coated with great uniformity with an extremely thin film, and also whereby a relatively large number of cartridges may be coated in a short time and at small cost.

In the preparation of cartridges having metal cases for storage and for use, it has been found desirable to apply to said metal case a relatively thin coating of some protective substance which will preserve said metal case for comparatively long periods of time against-deterioration, such as season cracking. In the present invention, the material for said coating has been so chosen as to perform the additional function of acting as a lubricant for the case of the cartridge, both for facilitating introduction into the chamber of the gun and the extraction thereof after firing. The most suitable wax which I have found for this purpose and which I at present prefer is ceresin, a refined product of ozokerite; but I wish it to be understood that other waxes having similar qualities may exist which might serve equally well. Some of the desirable features of ceresin are that it is hard and non-tacky at ordinary temperatures having a melting point somewhere between 140 and 176 Fahrenheit. It is smooth and glassy when hard and does not gather dirt or dust. However, when the ceresin on the cartridges is melted in the chamber of a gun, it becomes a lubricant.

Other lubricating waxes have been employed for coating cartridges, and the method most generally pursued for applying said coating to the cartridge case has been to prepare a heated bath of a solution of the wax in a suitable solvent, dip the cartridges therein so that a film of the solution will adhere thereto, and finally withdraw the cartridges to permit the solvent to evaporate from the coating film. This former process is comparatively slow and has been found lacking in several important respects.

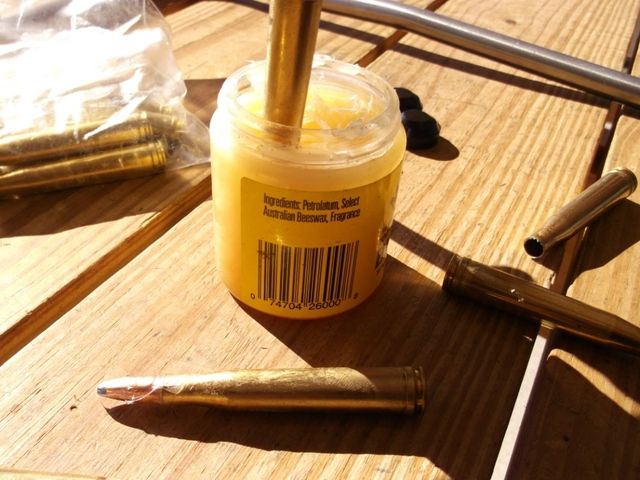

I regularly lube cases on first firing. Especially expensive cases like these belted magnum cases. I want the case to expand to the chamber without any side wall stretch as the base to shoulder distance is not controlled in belted magnums. Once the are fire formed to the chamber I only bump the shoulder back a couple of thousandths, and don’t have to lube them again, before firing, unless they are shot in a different rifle. Lubricated cases shoot fine.

I am only doing what a World Champion Benchrest shooter advices: Mike Ratigan, National and World Champion short range BR, in his book "Extreme Rifle Accuracy" advocates lubing the case with light oil because in his words:

"When the case starts to pressure up, it won't grip the sides of the chamber because of the oil" He goes on to say "This will allow the case to be forced back up against the bolt face and it will stay there without stretching the web area...."

Who here has more gravitas than a World Champion bench rest shooter?

I experimented with greased bullets to see if there would be any pressure problems, there was not. Grease that was not blown up the barrel was squeezed back through the action. Accuracy was fine. Greased bullets were used extensively by a number of militaries to reduce jacket fouling.

I have lots more pictures but this forum only allows six pictures per post.