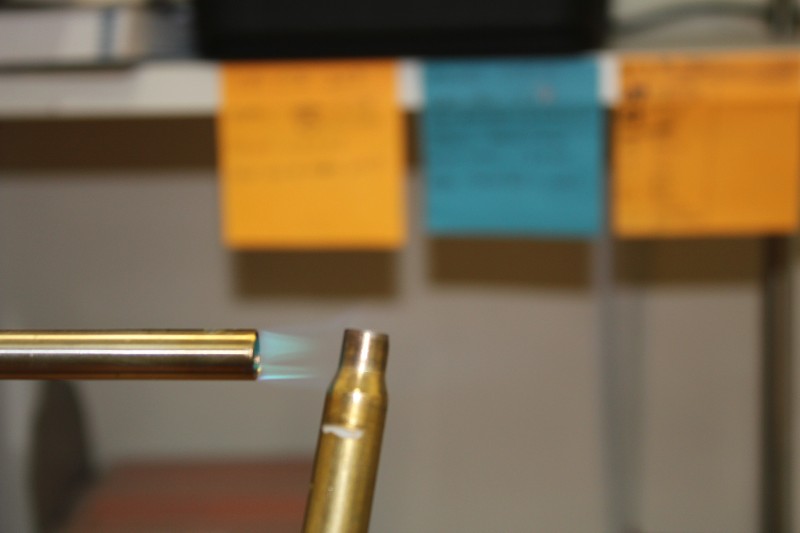

I can't believe this thread is still open but I'll post this pic of what my cases look like before annealing to stay on topic lol

How ever I'll join the totally off topic part of it

It's 100% true . Back before I started using competition shell holders . I would use shims under the case head in the shell holder to fine tune my case sizing .

This worked great when cases sprang back a tad more then you wanted . At times I would need just a tad more to be sized so I'd apply thicker amount of sizing wax to the case and run it through again . Through trial and error I was able to judge the amount needed to get .0005 more bump and not get any case dents .

Then when I started using the competition shell holders I was still using the wax lubes . The comp shell holders size in .002 increments and I found that those increments fell in between my desired case head space lengths I was trying to size my cases to . Knowing how I used to manipulate the sizing process with lube before I thought I'd try it again with the comp shell holders . The interesting finding for me was rather then adding more wax lube ( which is hard to do consistently ) . I found changing lube all together was better . I went to Hornady's one shot and all my cases sized to a different size ( bigger ) by .0005 to .001 . which put me right were I wanted to be all along . My conclusion was that the oneshot when applied has a much thinner coating on the case allowing the case to be sized a tad longer at the same die setting .

So yes IMO lubes , which ones and how much used has an effect on your sized cases length ( datum to head ) .

How ever I'll join the totally off topic part of it

I believe this is true, but have not tried to measure it.

It's 100% true . Back before I started using competition shell holders . I would use shims under the case head in the shell holder to fine tune my case sizing .

This worked great when cases sprang back a tad more then you wanted . At times I would need just a tad more to be sized so I'd apply thicker amount of sizing wax to the case and run it through again . Through trial and error I was able to judge the amount needed to get .0005 more bump and not get any case dents .

Then when I started using the competition shell holders I was still using the wax lubes . The comp shell holders size in .002 increments and I found that those increments fell in between my desired case head space lengths I was trying to size my cases to . Knowing how I used to manipulate the sizing process with lube before I thought I'd try it again with the comp shell holders . The interesting finding for me was rather then adding more wax lube ( which is hard to do consistently ) . I found changing lube all together was better . I went to Hornady's one shot and all my cases sized to a different size ( bigger ) by .0005 to .001 . which put me right were I wanted to be all along . My conclusion was that the oneshot when applied has a much thinner coating on the case allowing the case to be sized a tad longer at the same die setting .

So yes IMO lubes , which ones and how much used has an effect on your sized cases length ( datum to head ) .

Last edited: