Yes. And all the parts have mass, which has inertia, so there isn't always time for forces that would otherwise exceed the yield to move the metal far enough to do it before the force has vanished. A rule of thumb that Slamfire has pointed to before (from Art Pejsa?), was to calculate a safety factor of two for bolt lugs based on static conditions. But when you look at Varmint Al's dynamic FEA analysis, the actual pressure on the lugs in a firing event turns out to be only about half what the static analysis predicts, so, for practical purposes it is actually a safety factor of four. The dynamics of rapid events affect actual stress and strain significantly.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Overcharges?

- Thread starter Mosin-Marauder

- Start date

I have NEVER been able to get a failure in a gun based on the calculated stress from chamber pressure. It has been suggested to me that a 1 millisecond stress just does not do much compared to the rated tensile strength for a given steel. Plastic deformation takes time. When they plot that 4140 RC28 tensile strength, they give the sample piece of steel lots of time to stretch.

We, as members in reloading forums, discuss pressure and ways of measuring. I have always insisted it would be nice if someone could figure a way to have something else in the chamber besides a means of measuring pressure. I have always insisted I have something in the chamber every time I pull the trigger. I call it 'A CASE". I have wrecked a few cases, 45 firings?

I have cases that never made it to the second firing, I know, there are those that get 45 firings.

Then there is the Japanese T-type rifle, forget the rifle, I want the cases, if the cases made it through all that super high pressure I want the cases. And still, none of my T-Type Japanese receiver rings have one complete thread.

F. Guffey

In strong firearms where the case is the weak link, I focus on the pressure sign on the case, case life, and case reliability.

There are a lot of handloaders who navigate by SAAMI registered max average pressure and subsequent published max loads.

In engineering there are two political parties:

1) Do it per procedures

2) Get-r-done

Most of my relatives are engineers and we are divided.

There are a lot of handloaders who navigate by SAAMI registered max average pressure and subsequent published max loads.

In engineering there are two political parties:

1) Do it per procedures

2) Get-r-done

Most of my relatives are engineers and we are divided.

There was one point that seems to have been ignored. Some cartridges are deliberately kept at low pressures due to the fact they originally came in what are considered rifles too weak for modern pressures. The 7x57 immediately comes to mind and it's only through careful hand loading that one finds it's true potential. The .257 Robt. is another in factory loadings because many custom lightweight rifles were based on those same 93 and 95 Mausers that keep the 7x57 low powered.

Handloading manuals for the most part keep data on the weak side for the same reason. It would be nice if they gave a section for modern pressure loads to be used in currently made rifles that are also chambered to modern loads. I load for both the above mentioned cartridges in modern Winchester M70 Featherweights and while I trust the integrity of my handholds, it would be nice to see data corroborating my efforts. I feel that if they can do it for the 45-70 and .45 Colt cartridges, why not for the 7x57 and .257 Bob?

Paul B.

Handloading manuals for the most part keep data on the weak side for the same reason. It would be nice if they gave a section for modern pressure loads to be used in currently made rifles that are also chambered to modern loads. I load for both the above mentioned cartridges in modern Winchester M70 Featherweights and while I trust the integrity of my handholds, it would be nice to see data corroborating my efforts. I feel that if they can do it for the 45-70 and .45 Colt cartridges, why not for the 7x57 and .257 Bob?

Paul B.

Jim Watson

New member

The .257 Robt. is another in factory loadings because many custom lightweight rifles were based on those same 93 and 95 Mausers that keep the 7x57 low powered.

This is something I have been disputing for a long time.

There never was a factory made .257 Roberts on a weak action, it was introduced in the Remington Model 30, soon followed by Winchester Models 54 and 70. The ammo companies never cared that Bannerman had been crudely reaming Mosin Nagants for .30-06 or that some gunsmith might put a .270 barrel on some old action. Why should they download an all new round based on what a gunsmith might assemble?

Also most of those Spanish Mauser builds were for the .25 Roberts wildcat (two versions, Neidner and G&H) which was not interchangeable with factory .257 Remington Roberts.

I think the .257 Roberts was lightly loaded because that was the usual route to accuracy in those days, the bullets would not stand high velocity. Don Zutz, in a rare departure from writing about shotguns, shot a pre-WWII .257 with 1990s bullets and found it more accurate than the old timers reported, and that the accuracy held up to high velocity.

Note that much recent production .257 Roberts ammo is labeled +P which means it is loaded clear up to .30-06 pressure levels. Like that was tough.

And still, none of my T-Type Japanese receiver rings have one complete thread.

Not one complete thread, down one side of the receiver there is a 'GASH

F. Guffey

Jim Watson

.. The ammo companies never cared that Bannerman had been crudely reaming Mosin Nagants for .30-06..

Societies have traditionally had pyramids of organization, with bosses above and lackies below.

This worked well when tasks were simple physical work. The boss knew how to dig a ditch and had a fast visual feedback to find if you didn't.

But as the work became mental, and the grunt on the bottom knew the most, all kinds of problems ensued. Dilbert cartoons express the absurdities of being told what to do by important ignoramus.

As I travelled around as a consulting engineer, I rated companies by how many dilbert cartoons they had on the wall. At one aerospace company I found a building made for 1,000 employees, filled with 50 employees, and seemingly thousands of Dilbert cartoons. In 3 months I redesigned the 777 battery charger aux to meet EMI and left. The building was sold a month later.

Based on my model of which companies would be afraid to take risks, I developed my own investment system. AMZN was $10 when I bought it 14 years ago. It it $659 now.

I would not invest in SAAMI, Winchester, or Remington.

A rule of thumb that Slamfire has pointed to before (from Art Pejsa?), was to calculate a safety factor of two for bolt lugs based on static conditions.

I found several sources for the safety factor of two. Brassey's Essential Small Arms http://www.amazon.com/Brasseys-Essential-Guide-Military-Small/dp/1857531078, Lilja Bolt Lug strength, http://riflebarrels.com/a-look-at-bolt-lug-strength/, an Armalite designer and a Cannon designer. This safety factor of two is based on a simple maximum shear analysis. Springfield Armory used Van Mises and applied different safety factors based on their X, Y, Z orientation. Springfield Armory used overly large safety factors and I believe that was because they used ID in their thrust calculations, which is the wrong way to do it, would undersize the load, and then compensated by using larger than normal safety factors.

Safety factors are traditional, based on historical practices, can change as the material technology changes. They are also valid for duty cycles and load environments. So, what is a reasonable duty cycle for a personnel sidearm?

The factor of two safety factor is based on the assumption that the case does not carry load.

But when you look at Varmint Al's dynamic FEA analysis, the actual pressure on the lugs in a firing event turns out to be only about half what the static analysis predicts, so, for practical purposes it is actually a safety factor of four

Are you looking at the numbers from this Varmit Al analysis ? / http://www.varmintal.com/a243z.htm Are you looking at the dry case/dry chamber numbers? How does a designer ensure that the chamber and case will always be dry?, or that the friction between the two a constant? Given the last one is impossible to predict to predict in service, what coefficient of friction would a designer use?

The ammo companies never cared that Bannerman had been crudely reaming Mosin Nagants for .30-06

These rifles were sold to the public well before the concept of consumer protection and product liability were conceived. Back then, it was strictly, buyer beware! It was a time when fatalities were expected at work. As a data point, the ship builder Harland and Wolff, one man died per 10,000 tons of ship production. Since an average ship was about 15,000 tons, one man died per ship launched. Payoff for the dead was a funeral and 100 pounds. That was the way it was, and if you did not like it, you did not have to show up for work.

The Imperial German Army had hundreds of thousands of captured M1891's and they sent theirs off to be converted to 8mm Mauser. One of Dr Dieter Storz's books show a picture of the conversion. It was dangerous as heck, as probably the Bannerman conversions are. Here is an example of a Bannerman conversion. https://www.youtube.com/watch?v=KI7BCToQhRc The problem with both the German and Bannerman conversions is the chamber was reduced in length. What is not understood by most Americans, Hatcherities and Ackley ites, and especially not the guy in the video, is that a rifle chamber carries much more load than the locking lugs. The surface area of the chamber is greater, therefore the load carried by the chamber is much greater, than the load on the bolt face. This explains why there is so much metal over the cartridge area, and why it tapers as the pressure curve drops. For the Bannerman conversions, the cartridge is supported by a barrel section that is too thin, in terms of hoop stress, for the pressure at that point. You can see how much chamber has been cut away around minute seven of the video, and since the 30-06 is longer, you can imagine just how much of the cartridge case is sticking into the thinnest barrel section.

The Germans found that their 8mm conversions would blow and they never allowed live ammunition to be fired in their conversions. They ended up using the things as drill rifles only. Bannerman conversions, those that have not blown yet, will, given enough load cycles. I am of the opinion that the steel is dangerously overstressed, and looking at the S/N curve that Unclenick displays, just imagine how many load cycles such a conversion can take, before it fails through metal fatigue. The shooter in the video fires five cartridges and nothing happened. I would have liked to see him shoot one thousand. It is my opinion, with full power cartridges, that rifle barrel would have ruptured before 1000 rounds went through it.

If you had 100,000 psi chamber pressure and a 0.47" chamber diameter and steel that yield a 120 ksi, the thickness needed per thin wall hoop stress would be:

S = P [ID]/ 2[wall thickness]

I asked my father where he got that formula and he screamed at me, "From inspection!"

wall thickness = P[ID]/2S = 100kpsi [.47]/2 120ksi = 0.196" thick walls

OD = ID + 2 [ID] = .86" outside diameter of barrel around the chamber.

That is a skinny breech.

The gun will not blow up with 100 kpsi chamber pressure.

S = P [ID]/ 2[wall thickness]

I asked my father where he got that formula and he screamed at me, "From inspection!"

wall thickness = P[ID]/2S = 100kpsi [.47]/2 120ksi = 0.196" thick walls

OD = ID + 2 [ID] = .86" outside diameter of barrel around the chamber.

That is a skinny breech.

The gun will not blow up with 100 kpsi chamber pressure.

If you had 100,000 psi chamber pressure and a 0.47" chamber diameter and steel that yield a 120 ksi, the thickness needed per thin wall hoop stress would be:

S = P [ID]/ 2[wall thickness]

I asked my father where he got that formula and he screamed at me, "From inspection!"

wall thickness = P[ID]/2S = 100kpsi [.47]/2 120ksi = 0.196" thick walls

OD = ID + 2 [ID] = .86" outside diameter of barrel around the chamber.

That is a skinny breech.

The gun will not blow up with 100 kpsi chamber pressure.

Clark: I don't know or what you were replying to in this post, but I am going to address it as a reply to my Bannerman Mosin Nagant conversion.

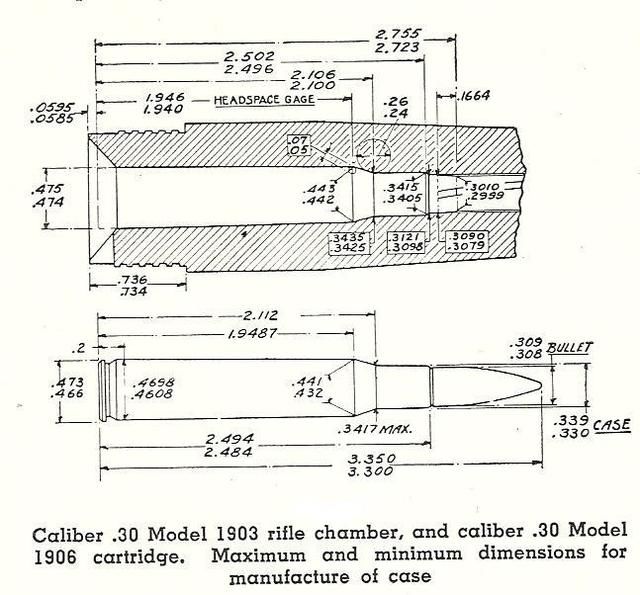

Bannerman conversions, those that have not blown yet, will, given enough load cycles. I am of the opinion that the steel is dangerously overstressed. I took some measurements from a M1891/30 Sniper that I own. My measurements have error, the dial caliper is likely out of calibration, and my measurements are crude. I measured the forward chamber shoulder on my Mosin and it is 1.80" in diameter. The barrel tapers aggressively forward of the chamber, and I measured the barrel diameter at the base of the rear sight, just in front of the sight blade. I was very lazy, I did not uncork the action from the stock and take more exact measurements. The 30-06 case is 2.494" long, I don't know just how much of the Nagant barrel was cut off in the conversion, so I did not try to estimate how much of the 30-06 case would be in the thin barrel section. I just made a SWAG that the case shoulder would be located at the rear sight base. The barrel actually tapers more, the taper slightly increasing towards the muzzle, so, if the barrel was cut back more, the chamber reamed deeper, the barrel only gets thinner. The diameter of my barrel at the rear sight base is 0.765". Plus or minus the inaccuracy of my caliper. The chamber dimension I have, the 30-06 reamer cuts the shoulder diameter to 0.443". I will use these numbers later, but I am going to address period materials.

It is a total mistake to assume vintage guns used contemporary materials. So many people who lack an understanding of history project back today's technologies and just assume the ancients had cell phones, satellite data, modern materials, CNC machines and grooved to Rock Music. This was not so. Millions of Mosin Nagants were made before vacuum tubes were invented. The material technology of the era was quite primitive. Plain carbon steels were state of the art and that is what was used in vintage rifles and pistols. These are data points I found about metal history, and they show the relative primitive state of metallurgy prior to WW1.

Silicon Steel patented in 1886

Manganese Steel licensed to use in US in 1890

Nickel Steel Armor adopted in by US Navy1891,

1910 Monnartz & Borchers patented Stainless Steel

Those steels and dates won't mean much to many, neither will the reference to vacuum tubes, infact, I expect the comparisons will be puzzling for many. So many people were born after vacuum tube technology ended, born after the era of six transistor radio's, in fact were born well after integrated circuit chip technology, that using vacuum tubes or transistors as examples of technological advancements won't make any impression at all. But I remember vacuum tube radios, and I remember the cat's eye tuner on the front of my Sears Silvertone vacuum tube shortwave radio.

I don't know what materials were used in Mosin Nagant barrels and receivers. I am going to make the assumption they used the same plain carbon steels the US Army used in the manufacture of the M1903 rifle. I have no reason to assume the Russians used alloy steels at any time during what has to be a century of manufacturing Mosin Nagants. If someone has metallurgical data contradicting this, please put it out in the public domain.

Source: July-Aug 1928 issue Army Ordnance, “Heat Treatment and Finish of Small Arms at Springfield Armory"

Springfield Armory used steels they called "Class A, Class C", etc in the manufacture of the various components of the M1903 rifle. Class C steel was used for receivers and bolts, and Class A for barrels.

Code:

Carbon Manganese Max Phos Max Sulpher Component

Class C Steel .20-.30 1.0-1.30 . .050 .050 Receivers

Class A .45-.55 1.00-1.30 .050 .050 BarrelsThis is from the article:

Barrels are rolled from the bar stock to a rough shape. After rolling, the barrel blanks are normalized at 1650 °F and annealed at 1600 °F for two hours. They are then hardened by heating in an open ifre to 1550 °F for one hour and then quenching in oil. They are tempered to meet the following physical specifications:

Yield Point, 75,000 lbs per sq. in.

Tensile Strength 110,000 lbs. per sq.in.

Elongation 20.0 per cent.

Contraction of Area, 50.0 per cent.

The standard .505 inch tensile test specimen is prepared from the breech end of the barrel blank. Each barrel blank is given a Brinell hardness test and must be between 228-269

The yield strength is 75,000 psia, you would expect an alloy steel to be around 90,000 lbs, if not more. Alloy steel yield varies considerable by what alloys are used, and what hardness is desired but it turns out that barrels are in fact fairly soft. Toughness is more desired than hardness and yield strength is traded for increases in toughness. Brittle is not a desired barrel material characteristic.

I used a thin walled pressure vessel calculator I found on the web to calculate hoop stresses. So based on these dimensions, the yeild strength of Class A materials, and assuming a 30-06 in the chamber, I get these numbers for hoop stress.

30-06 case shoulder at forward edge of Mosin Nagant chamber

Wall thickness (1.80"-0.443")/2 = 0.6785"

Cartridge Pressure =50,000

Material Yield = 75,000

Hoop stress= 66,273 psia.

30-06 case shoulder just at Mosin Nagant rear sight base

Wall thickness (0.765"-0.443")/2 = 0.161"

Cartridge pressure = 50,000 psia

Material Yield = 75,000 psia

Hoop stress= 118,788 psia.

There are known unknowns in this calculation. Pressures vary quite a bit, what we see given as a pressure in a reloading manual is an average. Maximum pressures are typically 20% higher than the average, sometimes higher than that. Material values have uncertainty, no metal will have an exact yield strength of 75,000 psia, or 100,000 psia, because metal strength varies. That is why margins are used in the design of mechanical items. Designing something with a calculated hoop stress of 75,000 psia and using a material with a yield of 75,000 is a guaranteed path to a catastrophic failure. There are rash, irresponsible people who would do this, and get away with it for a while, but metal fatigue will catch up with them. The calculated hoop stress of 118, 788 psia, which is based on the assumption that the 30-06 case shoulder is forward of the original Nagant chamber, with a material that stretches at 75,000 psia, ought to be a clue that Bannerman conversions were not structurally well thought out. I have not looked at a S/N curve to estimate the fatique life of any of these potential situations, and I really don't want to. I expect the best case stress situation would have a predicted fatique life in the hundreds of cycles, assuming good metal. Given that Imperial Russian steel was pre vacuum tube technology, and Soviet steel was awful (based on discussions with a West Point Metallurgical Teacher) I would not trust a Bannerman conversion, or a Bannerman conversion of a WW2 era Mosin.

Last edited:

Slamfire

Clark: I don't know or what you were replying to in this post, but I am going to address it as a reply to my Bannerman Mosin Nagant conversion.

I did not know anything about Bannerman conversions, but I have now watched a video

I see in this video he addresses your concerns at ~ 8 minutes into it.

https://www.youtube.com/watch?v=KI7BCToQhRc

Slamfire

Clark: I don't know or what you were replying to in this post, but I am going to address it as a reply to my Bannerman Mosin Nagant conversion.

I did not know anything about Bannerman conversions, but I have now watched a video

I see in this video he addresses your concerns at ~ 8 minutes into it.

https://www.youtube.com/watch?v=KI7BCToQhRc

I linked to that video in post 50 and that was the primary reason I spent the time on this. That shooter did not address my concerns, he did not "address" any concerns, he just blew them off. He knew of the danger of those Bannerman conversions and being a confident idiot; ignored them. The fact he shot five cartridges is not proof the conversion is safe. I would like to see what happens after 1000 rounds.

While not my taste in personal grooming, I like that guy.

Ian McCollum is a self-described professional gun nerd, passionate about firearm design, manufacture, history, and practical use. He is always looking for rare, experimental, and unusual firearms to learn about, and loves sharing that interest with others.

Forgotten weapons.

Great show.

It is very seldom I come into contact with information about guns that is news to to me. But he finds guns so obscure, i have never even heard of them.

Not only that, while most gun writers are not technical, Forgotten Weapons has some Frank De Haas like content [engineer]. Speak'n my language.

https://www.youtube.com/user/ForgottenWeapons/videos

https://www.full30.com/channels/forgottenweapons

Ian McCollum is a self-described professional gun nerd, passionate about firearm design, manufacture, history, and practical use. He is always looking for rare, experimental, and unusual firearms to learn about, and loves sharing that interest with others.

Forgotten weapons.

Great show.

It is very seldom I come into contact with information about guns that is news to to me. But he finds guns so obscure, i have never even heard of them.

Not only that, while most gun writers are not technical, Forgotten Weapons has some Frank De Haas like content [engineer]. Speak'n my language.

https://www.youtube.com/user/ForgottenWeapons/videos

https://www.full30.com/channels/forgottenweapons

I like that guy.

And he makes no attempt to make himself look good at other's expense.

F. Guffey