You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mauser 98 bolt lugs case hardened or through hardened

- Thread starter mike8mm

- Start date

Dfariswheel

New member

To learn the fine details of Mauser rifles, I recommend buying the Jerry Kuhnhausen Shop Manual.

These manuals were written as training aids for new gunsmiths, and get way down deep into the details you can't usually find elsewhere.

The manual specifically addresses in detail the locking lugs, case hardening, and includes pictures of lugs with the case hardening lapped away

If you're working with a Mauser this is money WELL spent. It has information that's usually not available elsewhere.

http://www.brownells.com/gunsmith-t...ser-bolt-actions-a-shop-manual-prod25715.aspx

These manuals were written as training aids for new gunsmiths, and get way down deep into the details you can't usually find elsewhere.

The manual specifically addresses in detail the locking lugs, case hardening, and includes pictures of lugs with the case hardening lapped away

If you're working with a Mauser this is money WELL spent. It has information that's usually not available elsewhere.

http://www.brownells.com/gunsmith-t...ser-bolt-actions-a-shop-manual-prod25715.aspx

Mike Irwin

Staff

"The "tire test" has been around longer than I have."

Except when you were a kit, it was "tie the gun to a stone wheel..."

Except when you were a kit, it was "tie the gun to a stone wheel..."

The case, as applied in case hardening, is primarily a wear hardness surface. Case is still applied for modern alloy steels, such as nitriding, salt bath, etc for wear hardness. The habit of grinding off case layer in the shooting community to make parts "fit better" is a total folly and is an example of how foolish ideas become doctrinal behavior within a society. Once that case is removed you are down to a soft metal surface that will gall, wear, etc.

Case hardening is not meant to effect the heat treatment nor the "through hardness" of the steel. Carburizing requires hours of exposure to a carbon rich environment. Pre WWII it was common to pack parts in boxes that had bones, leather, etc, and heat the box and parts for hours and hours to develop a case surface. Around that time other more precise methods were developed, but all involve exposing steel to a carbon rich atmosphere and letting the carbon diffuse into the surface making the surface carbon rich and hard.

From all the data I have read, pre WW2 Mausers were made of plain carbon steels just like all of the other military firearms of the era. Plain carbon steels are inferior in all properties to alloy steels but they were state of the art in 1890, manufacturers are slow to change and legacy systems tended to use the same steels that they always had. The steels used in your Mauser would have been heat treated to withstand a 45,000 psia 8mm load. You could heat treat the material to a harder material, thus raising ultimate and yeild properties, but the material would be less tough. Toughness is a much more desired property in an environment where the load is basically a shock or impact load. The material would be heat treated just to the level needed to support the load and not more, as toughness would decrease.

Plain carbon steels were commonly used on parts prior to WW2, but metullurgy in the 1920's and 30's advanced so quickly that by the time you get to WW2 it is obvious that plain carbon steels are only a good choice if cost is the number one criteria and the loads are not high or safety critical. The steels used in pre WW2 rifles are now used as rebar, rail road ties, applications where the low load justifies the low cost.

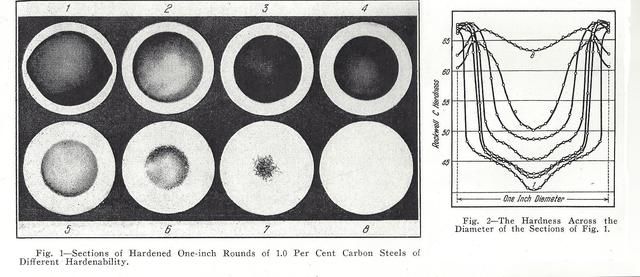

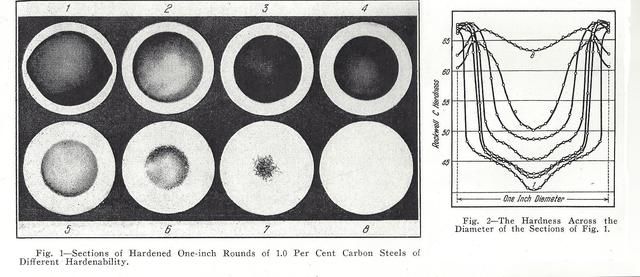

The American metallurgist Edgar Bain, http://www.nasonline.org/publications/biographical-memoirs/memoir-pdfs/bain-edgar-c.pdf in 1932 published conclusive experiments on carbons steels. Bain heat treated identical plain carbon steel coupons under identical conditions and examined the coupons afterwards for hardness depth. The black chemical etching, which I assume is the unhardened steel, show that plain carbon steels have erratic hardening depths, given that all else is equal. These steels were called in WW2 era text books as “shallow hardening”. This was meant not as praise but as a pejorative. As is shown on the right of the diagram, the hardness of these coupons varies by depth. This is not good as consistent hardening provides consistent material properties. It is undesirable to create parts some of which will be hard through and through but others soft below the surface even though the heating processes are the same for all parts. But use plain carbon steels, and you will create such inconsistent parts, just by the nature of the material.

Therefore, you would expect even properly forged, properly heat treated plain carbon steel parts to vary considerable in hardness depth, which then affects the properties of the end part.

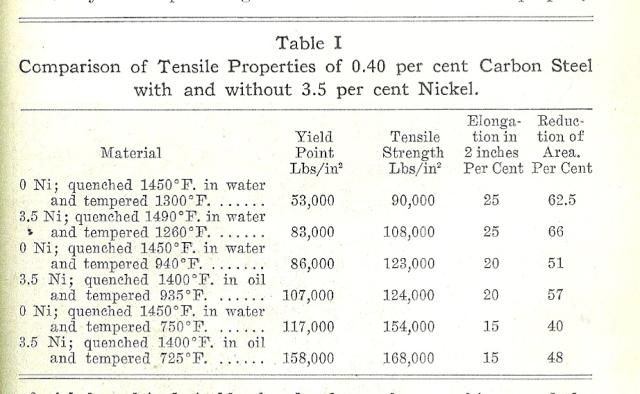

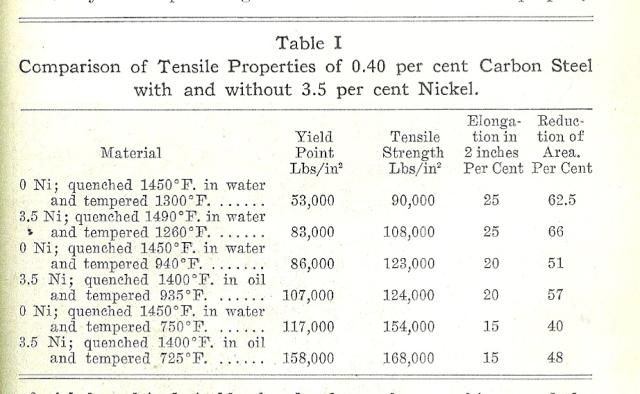

Yield is an extremely important material property, for above yield, the part deforms. Once a steel part yields it is no longer safe to use. What happens after yield is unpredictable, often it takes less load to cause more deformation, ultimate load is the load it takes to break the part. In this early 1920’s chart, for the same essential heat treatment, the nickel alloy steel always has a higher yield, a significantly higher yield in all cases, than the plain carbon steel.

Nickel steel versus plain carbon steel

What is not shown in these charts is a material property called toughness. For a device, such as a receiver, which is going to be subjected to impact loading, toughness is a highly desirable property. Toughness is directly related to fatigue lifetime, which is the number of loading cycles to failure. Assuming the yield is sufficient for the load, the tougher material will have a longer service life. Alloy steels have a greater toughness than plain carbon steels. Alloy steels take more energy to shear, Charpy impact tests are a direct predictor of a steel’s fatigue lifetime. It is a revelation to see just how shear energy decreases with temperature, and at low temperature, alloy steels take several times the energy to shear as do plain carbon steels.

Therefore, old plain carbon receivers are a very significant unknown quantity. We know that the material varies considerably in properties after heat treatment, and that the service life of the part will always be less to one made out of a good alloy steel. Just how many service lives have these old receivers been though? How many more load cycles will they take before failure? How will they react in an overpressure situation?

The fact that you have receiver set back in your rifle is of a great concern to me. The material has yielded indicating that an excessive load or loads have been fired in that rifle. Once a material yields, it takes less load to make it yield again (typically). It is your choice, but if you shoot the thing you better check the headspace to see if it is growing, and regardless, understand you are behind something that is less strong than it was when it was new. If that receiver had gone through a rebuild program, it would have been discarded if lug set back had been found.

Case hardening is not meant to effect the heat treatment nor the "through hardness" of the steel. Carburizing requires hours of exposure to a carbon rich environment. Pre WWII it was common to pack parts in boxes that had bones, leather, etc, and heat the box and parts for hours and hours to develop a case surface. Around that time other more precise methods were developed, but all involve exposing steel to a carbon rich atmosphere and letting the carbon diffuse into the surface making the surface carbon rich and hard.

From all the data I have read, pre WW2 Mausers were made of plain carbon steels just like all of the other military firearms of the era. Plain carbon steels are inferior in all properties to alloy steels but they were state of the art in 1890, manufacturers are slow to change and legacy systems tended to use the same steels that they always had. The steels used in your Mauser would have been heat treated to withstand a 45,000 psia 8mm load. You could heat treat the material to a harder material, thus raising ultimate and yeild properties, but the material would be less tough. Toughness is a much more desired property in an environment where the load is basically a shock or impact load. The material would be heat treated just to the level needed to support the load and not more, as toughness would decrease.

Plain carbon steels were commonly used on parts prior to WW2, but metullurgy in the 1920's and 30's advanced so quickly that by the time you get to WW2 it is obvious that plain carbon steels are only a good choice if cost is the number one criteria and the loads are not high or safety critical. The steels used in pre WW2 rifles are now used as rebar, rail road ties, applications where the low load justifies the low cost.

The American metallurgist Edgar Bain, http://www.nasonline.org/publications/biographical-memoirs/memoir-pdfs/bain-edgar-c.pdf in 1932 published conclusive experiments on carbons steels. Bain heat treated identical plain carbon steel coupons under identical conditions and examined the coupons afterwards for hardness depth. The black chemical etching, which I assume is the unhardened steel, show that plain carbon steels have erratic hardening depths, given that all else is equal. These steels were called in WW2 era text books as “shallow hardening”. This was meant not as praise but as a pejorative. As is shown on the right of the diagram, the hardness of these coupons varies by depth. This is not good as consistent hardening provides consistent material properties. It is undesirable to create parts some of which will be hard through and through but others soft below the surface even though the heating processes are the same for all parts. But use plain carbon steels, and you will create such inconsistent parts, just by the nature of the material.

Therefore, you would expect even properly forged, properly heat treated plain carbon steel parts to vary considerable in hardness depth, which then affects the properties of the end part.

Yield is an extremely important material property, for above yield, the part deforms. Once a steel part yields it is no longer safe to use. What happens after yield is unpredictable, often it takes less load to cause more deformation, ultimate load is the load it takes to break the part. In this early 1920’s chart, for the same essential heat treatment, the nickel alloy steel always has a higher yield, a significantly higher yield in all cases, than the plain carbon steel.

Nickel steel versus plain carbon steel

What is not shown in these charts is a material property called toughness. For a device, such as a receiver, which is going to be subjected to impact loading, toughness is a highly desirable property. Toughness is directly related to fatigue lifetime, which is the number of loading cycles to failure. Assuming the yield is sufficient for the load, the tougher material will have a longer service life. Alloy steels have a greater toughness than plain carbon steels. Alloy steels take more energy to shear, Charpy impact tests are a direct predictor of a steel’s fatigue lifetime. It is a revelation to see just how shear energy decreases with temperature, and at low temperature, alloy steels take several times the energy to shear as do plain carbon steels.

Therefore, old plain carbon receivers are a very significant unknown quantity. We know that the material varies considerably in properties after heat treatment, and that the service life of the part will always be less to one made out of a good alloy steel. Just how many service lives have these old receivers been though? How many more load cycles will they take before failure? How will they react in an overpressure situation?

The fact that you have receiver set back in your rifle is of a great concern to me. The material has yielded indicating that an excessive load or loads have been fired in that rifle. Once a material yields, it takes less load to make it yield again (typically). It is your choice, but if you shoot the thing you better check the headspace to see if it is growing, and regardless, understand you are behind something that is less strong than it was when it was new. If that receiver had gone through a rebuild program, it would have been discarded if lug set back had been found.

Thank you for your invaluable help. interesting information.

I found many old mauser receivers suffer from the same setback in upper recess area, I think ( or I would rather hope in fact! ) that it is mostly a design failure rather than material failure. The reason for this kind of setback is that the split lug on bolt had a very sharp edge that instantly attack the recess upon firing.

What do think about it, of course it is only an idea nothing more and I am not an expert by any means in this field.

Again many thanks for interesting write up and the time you put on this

God bless

I found many old mauser receivers suffer from the same setback in upper recess area, I think ( or I would rather hope in fact! ) that it is mostly a design failure rather than material failure. The reason for this kind of setback is that the split lug on bolt had a very sharp edge that instantly attack the recess upon firing.

What do think about it, of course it is only an idea nothing more and I am not an expert by any means in this field.

Again many thanks for interesting write up and the time you put on this

God bless

Again many thanks for interesting write up and the time you put on this

Glad to be of help. I decided to educate myself on this topic, do my own research, and if I can help others understand their firearms a bit better, than it is all to the good.

The more I have learned, the more I have learned how little gun writers, who are the primary educators of the shooting community, don't know what they are talking about. For decades these guys have been spreading nonsense, such as "old world craftsmanship", and "German technology", all meaningless, and misleading information on old rifles and actions. When you research the history of technology, the history of metallurgy, you find they are totally clueless and that these old rifles have risks which are inherent due to the production technology of the era, the metallurgy used, and probably some more criteria if I could think of them.

mike8mm,

With the amount of work you've done on that Persian, I expect you'll rebarrel someday.

When you do, send the receiver and bolt out for gas carburizing after you lap the lugs again and true up the bolt face. When you get the parts back, install the barrel and set headspace and I wouldn't worry about the action again.

Jimro

With the amount of work you've done on that Persian, I expect you'll rebarrel someday.

When you do, send the receiver and bolt out for gas carburizing after you lap the lugs again and true up the bolt face. When you get the parts back, install the barrel and set headspace and I wouldn't worry about the action again.

Jimro

Jimro, thanks for your advice, the barrel is pitted but accuracy is good, I can shoot 10 shots 0.5 inch groups at 100 yards ftom a gunvise shooting my hanloads but it's on my list to rebarrel as my next project, I firelapped and recrowned the barrel too, and Copper fouling is much less and easier to clean now. Although the freebore grew longer by 1/16 of an inch I can not see any difference in accuracy.

God bless

God bless

Yesterday I went shooting , here is the report

3shot groups were still good but 10 shots groups was opened up. I let the barrel cool between shots.

Fortunately after 60 shots of mild and hot loads I can not see any difference in headspace, these loads were crash fit in the chamber because I had loaded them before lapping. when I had not set the headspace to standard go guage size. They were between

0.001 to 0.004 of an inch large than the new chamber size. Do you think this makes my tests void???

Barrel crown is another suspect area because I cut a very sharp zero degrees crown . of course the edge of the crown is still sharp after range session but I could see fouling accommodated on outer edge that was very hard to scratch after a few shots maybe it can cause flayers.

I also noticed a small contact area between the barrel and the stocks barrel channel at the very tip of the stock near the bipod mounting place.

Any help?

The velocity were as the following table for 3shots strings

42.5 gn. average 2165 ES.26 SD13

43 gn. Average 2187 ES.16 SD.7.80

43.5 average 2255 ES.27 SD.14

44 average 2295 ES.35 SD.18

44.5 average 2330 ES? ? SD. ???

45 grains average 2349 ES.15 SD. 7.5

powder unknown milsurplus which I had a quantity from old times and I have to use them up.

bullet Sierra prohunter 175 grns.

Total shots fired 60

I can see two barrel harmonic areas of 43 and 45 gns powder charge.

A picture of new crown is attached

God bless

3shot groups were still good but 10 shots groups was opened up. I let the barrel cool between shots.

Fortunately after 60 shots of mild and hot loads I can not see any difference in headspace, these loads were crash fit in the chamber because I had loaded them before lapping. when I had not set the headspace to standard go guage size. They were between

0.001 to 0.004 of an inch large than the new chamber size. Do you think this makes my tests void???

Barrel crown is another suspect area because I cut a very sharp zero degrees crown . of course the edge of the crown is still sharp after range session but I could see fouling accommodated on outer edge that was very hard to scratch after a few shots maybe it can cause flayers.

I also noticed a small contact area between the barrel and the stocks barrel channel at the very tip of the stock near the bipod mounting place.

Any help?

The velocity were as the following table for 3shots strings

42.5 gn. average 2165 ES.26 SD13

43 gn. Average 2187 ES.16 SD.7.80

43.5 average 2255 ES.27 SD.14

44 average 2295 ES.35 SD.18

44.5 average 2330 ES? ? SD. ???

45 grains average 2349 ES.15 SD. 7.5

powder unknown milsurplus which I had a quantity from old times and I have to use them up.

bullet Sierra prohunter 175 grns.

Total shots fired 60

I can see two barrel harmonic areas of 43 and 45 gns powder charge.

A picture of new crown is attached

God bless

Attachments

Last edited:

If you are going to push loads that light, I wouldn't worry too much about lug setback. Headspace will probably grow a tad over several hundred rounds, but those loads are pretty mild for an 8x57.

For what it is worth, I like 185gr Rem bullets over 45gr of IMR4064 for a very mild but accurate hunting load.

Jimro

For what it is worth, I like 185gr Rem bullets over 45gr of IMR4064 for a very mild but accurate hunting load.

Jimro

Gunplummer

New member

Slamfire, You are absolutely correct on your opinion. Even worse is dealing with a customer that read that crap or believes those rumors. Mauser or not, I have always been careful with models produced before or during WWI. I think the metallurgy was there at the time, but the testing was kind of "Loose". There was an '03 "Parts gun" on GunsAmerica last week. It became parts by firing it. Maybe someone messed with it, I wasn't interested enough to inquire.

**I am guessing "Crash fit" means they are not full length sized. I don't know about that, but if you full length sized AND trimmed the brass, set back would more than likely be showing by now. The OAL of the fired case would be slowly changing (Getting longer) after 60+ rounds. I actually experienced this with someone's rifle, but it was a .257R

**I am guessing "Crash fit" means they are not full length sized. I don't know about that, but if you full length sized AND trimmed the brass, set back would more than likely be showing by now. The OAL of the fired case would be slowly changing (Getting longer) after 60+ rounds. I actually experienced this with someone's rifle, but it was a .257R

Last edited:

Thank you for your posts.

When I lapped the barrel, haedspace grew by 8 tho", then I set the barrel back by 12 tho, so currently I have a chamber that is 4 thou smaller than what it was before lapping.

These handlads were loaded before lapping and I had partially full sized them to previous chamber size. But now these handloads are 4 tho larger than new chamber size. I don't know if I shoot the remaining cartridges or salvage the components and load them again to new chamber size.

I used to load up to 48 grns of this powder but it kicked like a mule, so I decided to test lighter loads but with 2300 ish velocity I don't think I would continue loading like this.

You are right, I think if I ever use one of those factory load which is full sized for the smallest chamber, I expect to see the setback happens again.

As a handloader I have freedom to size my cases to whatever size my guns chamber is, I think I would size exactly yo chamber size from now on.

Thanks again

God bless

When I lapped the barrel, haedspace grew by 8 tho", then I set the barrel back by 12 tho, so currently I have a chamber that is 4 thou smaller than what it was before lapping.

These handlads were loaded before lapping and I had partially full sized them to previous chamber size. But now these handloads are 4 tho larger than new chamber size. I don't know if I shoot the remaining cartridges or salvage the components and load them again to new chamber size.

I used to load up to 48 grns of this powder but it kicked like a mule, so I decided to test lighter loads but with 2300 ish velocity I don't think I would continue loading like this.

You are right, I think if I ever use one of those factory load which is full sized for the smallest chamber, I expect to see the setback happens again.

As a handloader I have freedom to size my cases to whatever size my guns chamber is, I think I would size exactly yo chamber size from now on.

Thanks again

God bless

An interesting thing to understand about lapping:It will be the harder material that is cut.

This is because the grit will engage or embed in the softer material.The grit will become like the teeth of a file on the soft material.There will be little motion or friction,or cutting,on the soft material.Instead,the soft material will drive the grit to cut the hard material.

Speculating:The setback in the receiver will detent the bolt in the locked closed position if the brass is pushed hard enough.This will require modest loads or you will get difficult bolt lift.

The setback area creates a two stage headspace condition in your rifle.As you chamber,to turn the bolt down,the locking lugs must climb over the non-setback area.As the shoulder of the cartridge is in contact with the shoulder of the chamber,the sized length of the cartridge case must be short enough to provide no interference.Zero head clearance or more.

Then the locking lugs fall into the setback area.This distance,the setback,is added to the headspace/head clearance.The point of saying all that is you are going to have case stretch.

You may already understand case stretch,Brass thinning,the stretch ring,case separation,hot gas,the paper clip test,etc.If so,great!!If not,its important to learn.If you load moderately and get acceptable brass life,shoot it as long as you are having fun.That setback wont cause the gun to come apart but you may begin to get case separations.Then,I'd hang it up.And do wear shooting glasses.

Folks still have Milsurp and commercial 98 Mauser actions under benches and in drawers..for that "some day" project.Look around you may find a better receiver.You will want to have the face of the receiver ring trued on a mandrel in a lathe.You now know how to look for setback.You may be able to find a commercial Mauser bolt.Saves modding the handle,and its modern steel.

With a little attention to bedding,you can drop your new bbl'd action into your "chassis"

It goes without saying,none of that makes economic sense,but what we do for fun seldom does.

This is because the grit will engage or embed in the softer material.The grit will become like the teeth of a file on the soft material.There will be little motion or friction,or cutting,on the soft material.Instead,the soft material will drive the grit to cut the hard material.

Speculating:The setback in the receiver will detent the bolt in the locked closed position if the brass is pushed hard enough.This will require modest loads or you will get difficult bolt lift.

The setback area creates a two stage headspace condition in your rifle.As you chamber,to turn the bolt down,the locking lugs must climb over the non-setback area.As the shoulder of the cartridge is in contact with the shoulder of the chamber,the sized length of the cartridge case must be short enough to provide no interference.Zero head clearance or more.

Then the locking lugs fall into the setback area.This distance,the setback,is added to the headspace/head clearance.The point of saying all that is you are going to have case stretch.

You may already understand case stretch,Brass thinning,the stretch ring,case separation,hot gas,the paper clip test,etc.If so,great!!If not,its important to learn.If you load moderately and get acceptable brass life,shoot it as long as you are having fun.That setback wont cause the gun to come apart but you may begin to get case separations.Then,I'd hang it up.And do wear shooting glasses.

Folks still have Milsurp and commercial 98 Mauser actions under benches and in drawers..for that "some day" project.Look around you may find a better receiver.You will want to have the face of the receiver ring trued on a mandrel in a lathe.You now know how to look for setback.You may be able to find a commercial Mauser bolt.Saves modding the handle,and its modern steel.

With a little attention to bedding,you can drop your new bbl'd action into your "chassis"

It goes without saying,none of that makes economic sense,but what we do for fun seldom does.

Gunplummer

New member

Funny you should say that. Last night I was rummaging through tool boxes looking for some reloading stuff and found a Mark III receiver I did not know I had. I have bought receivers I found in boxes of junk at flea markets and yard sales. You are right, they are out there yet.

HiBC, thanks for your post, I am a hobby machinist and I know that soft steel is more abrasions resistance than hatd materials, but I had never thought of lapping this way! So thank you for this point.

I know about internal mechanism of mauser receivers too, and I will keep a sharp eye on headspace problems. I also test all my cases for head separation by a paper clip though i have never faced one. I size minimum amount that is necessary to chamber the cases and normally get several reloads before they fail, most of my problem s with case failure is due to primer pocket enlargement not the case head separation or the splits.

I am also a bit worried about the new crown I put on the barrel but because the barrel had a small contact area with the stock i have to do more tests to get sure about occasional fliers and the reason behind it. If it was the barrel contact or the new crown.

Your post was really informative thanks again.

God bless

I know about internal mechanism of mauser receivers too, and I will keep a sharp eye on headspace problems. I also test all my cases for head separation by a paper clip though i have never faced one. I size minimum amount that is necessary to chamber the cases and normally get several reloads before they fail, most of my problem s with case failure is due to primer pocket enlargement not the case head separation or the splits.

I am also a bit worried about the new crown I put on the barrel but because the barrel had a small contact area with the stock i have to do more tests to get sure about occasional fliers and the reason behind it. If it was the barrel contact or the new crown.

Your post was really informative thanks again.

God bless

Last edited:

Hi Jemro, have you ever tried to chrono your loads? Imr4064 seems the way to go.

God bless

No, I have not. Calculated velocity should be between 2,450 and 2,550 fps. Old Mauser barrels are notorious for shooting slower than they should, which lets a lot of handloaders load way hotter than is safe in a newer barrel.

2,300 fps with a 175gr pro hunter is still better than a 30-30 with a 170gr bullet. The spitzer profile means that it will hold velocity and momentum a lot better than the round nose 30-30 bullet too. So you already have a load that will take down any animal south of Canada with no problems. I wouldn't bump up the velocity if you have good accuracy where you are at.

Jimro

I think it is accurate enough up to 300 to 500 yards but I prefer a better load for up to 800 yards with less bullet drop.

I remember I watched a short video that a guy shot steel plates at 900 yards or so.

I liked the light recoil in that video, inspite the heavy load of 54 grains of imr4350 behind a hornady match 200 grns bullet. No mention of velocity but 2910 footpound energy at the muzzle of his 1941 98k German mauser.

Most of his shots were a hit.

As my rifle barrel's specs have been changed after I firelapped the barrel, I think I should restart load development all over again.

Though it is too soon to judge the results of my work on this rifle, I think the experience I gained in this project is worth the efforts, over all it was my first experience.

God bless

mike

I remember I watched a short video that a guy shot steel plates at 900 yards or so.

I liked the light recoil in that video, inspite the heavy load of 54 grains of imr4350 behind a hornady match 200 grns bullet. No mention of velocity but 2910 footpound energy at the muzzle of his 1941 98k German mauser.

Most of his shots were a hit.

As my rifle barrel's specs have been changed after I firelapped the barrel, I think I should restart load development all over again.

Though it is too soon to judge the results of my work on this rifle, I think the experience I gained in this project is worth the efforts, over all it was my first experience.

God bless

mike

Last edited: