I have a Persian mauser k98 circa 1935 in 8x57. The bolt had been changed when I bought it, plus I noticed a small setback on the recriver's lug recess. I took the barrel apart and lapped the lugs but it went more than what it should. Nearly 8 thou" .

The good thing is that it seems all that lapped material are gone from bolt lugs only and not from the recriver's. I say this because the headspace is increased the same amount as what it is removed from the back side of the bolt lugs.

Another good thing is that bolt lugs back surface still pass the file scratch test and are hard as what they were brfore lapping.

In short the whole process was like this:

the chamber was .012' longer than standard go guage, the first step.

Took the gun and barrel apart.

lapped the lugs by 0.008'

I had nearly 0.02" excess headspace now, both from the chamber being long and lapping process.

I cut about 0.01' from the chamber's end of the barrel on my lathe.

turned another 0.12 from the outer shank of the barrel but kept yhe chamner area intact (only to make the barrel enable to turn 1/6 turn more into the recriver) to compensate for breech to barrel distance that was increased

Cut 0.02' from recriver's face snd trued the C ring.

assembled the whole thing

Everything seems ok now, the chamber passed the go nogo guage test, the distance between bolt face protrusion and barrel face is 0.006 inch, and barrel is torqued and snug, But I am still worried about the hardness of bolt lugs.

do you have any idea on this , I know that the bolt and receiver are case hardened on mausers , but I got the idea that the lugs are probably hardened all through.

Thanks

Mike

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mauser 98 bolt lugs case hardened or through hardened

- Thread starter mike8mm

- Start date

Gunplummer

New member

They are not hardened through, or should not be. You are dealing with production guns from the 30's. The heat treating results will vary some what. Your initial test with the "GO" gage may have been off. I don't know if I ever checked a Mauser with SAAMI spec gages that passed. The Europeans had different specs for their guns and it will sometimes not crossover to ours correctly.

Art Eatman

Staff in Memoriam

Safety? The "tire test" has been around longer than I have.

Get an old tire from the tire shop. Set the butt into it, forearm laid across the opposite side and tied to the tire. Load it. Use a ten- or twenty-foot length of cord to pull the trigger. Or fishing line. Whatever. Rinse and repeat if you want.

Get an old tire from the tire shop. Set the butt into it, forearm laid across the opposite side and tied to the tire. Load it. Use a ten- or twenty-foot length of cord to pull the trigger. Or fishing line. Whatever. Rinse and repeat if you want.

Gunplummer

New member

I don't know about your process. Are you saying you lapped the bolt lugs outside (Separate) of the receiver? If you noticed setback in the receiver ring, why are you worried about the lugs on the bolt? Either way, if one or the other is too soft now it will show. Using American made factory rounds to start would be a good idea. I would keep an eye on the fired brass. If the setback continues, the brass will slowly be getting longer. Someone brought me a .257 R that did that. By the time he fired the 6th round it was noticable on the brass OAL with a dial calipers.

Thanks for your help gentlemen, I lapped the lugs while bolt inside the receiver, but the setback area is still there though it had become smaller. I can only feel a small click sound when I open the bolt and the bolt handle is 45 degrees up, it is at he very beginning of the so called ramp if I am not mistaken.

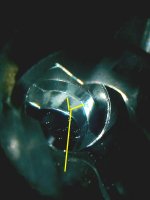

I will try shooting it tied yo a tyre, here id two pictures before and after lapping

I will try shooting it tied yo a tyre, here id two pictures before and after lapping

Attachments

As a reminder the setback had happened only in upper lug recess of the receiver, in fact it is where the split lug seats. Where the ejector slide inside. The upper bolt lug has most effect on the recess , people had the same problem in this area, I think lapping a mauser bolt lugs is a bad idea, the manufacturer has made those lugs so the there is no contact in this area, people lap the lugs to make more surface contact area and it will ruin the receiver

God bless

God bless

Gunplummer

New member

Uneven contact of locking lugs is common in military rifles, actually pretty much the norm. That is why lapping the lugs came about. Soft steel holds up better than most people think, although it will compress quickly when firing a few rounds. The strong receiver debate is in cases of catastrophic failure, which would be heavy overload, wrong ammo, blocked barrel, and so on. From what I have seen, the third lug on a Mauser won't stop the bolt dead, but it will slow it down before it can go too far.

[Re: Bolt lugs]

Can someone shed some light on this?

I was under the impression that only low/medium carbon steel can be case hardened (heated, infused with carbon and quenched) because if it is high carbon, when it is quenched to set the case harden, the steel would harden all the way through. Also, I was under the impression that Mauser bolts are high carbon or at least medium carbon steel (required for strength), hardened (through), and then draw to get toughness and get rid if the brittleness. I cannot believe that Mauser bolts are forged from low-carbon steel and then case hardened...I doubt that low carbon, even with a case, could withstand the pressures that come to bear when fired.They are not hardened through, or should not be.

Can someone shed some light on this?

Thank you gunplummer and all ,

dahrmit,

At least it is what most

people say on the net, I read in more than a few places that the metal is something in the range of 1020 or 1030 or 1330 low carbon steel. As I said in my first post the bolt lugs of my gun are 0.008 inch less on my dial and digital calipers after lapping but the lugs are still seem fine i.e they pass the file scratch test, I feel they are hard ad they were before lapping, I heard that if they pass the file test they're fine.

In the other hand I read some where that only bolt lugs and recriver's lugs are hardened through.

dahrmit,

At least it is what most

people say on the net, I read in more than a few places that the metal is something in the range of 1020 or 1030 or 1330 low carbon steel. As I said in my first post the bolt lugs of my gun are 0.008 inch less on my dial and digital calipers after lapping but the lugs are still seem fine i.e they pass the file scratch test, I feel they are hard ad they were before lapping, I heard that if they pass the file test they're fine.

In the other hand I read some where that only bolt lugs and recriver's lugs are hardened through.

Gunplummer said:

From what I have seen, the third lug on a Mauser won't stop the bolt dead, but it will slow it down before it can go too far.

##############

Gunplummer, do you mean that the third lug can not keep the shooter from being unsafe in case of a catastrophic accident, can you please elaborate on this.

God bless

From what I have seen, the third lug on a Mauser won't stop the bolt dead, but it will slow it down before it can go too far.

##############

Gunplummer, do you mean that the third lug can not keep the shooter from being unsafe in case of a catastrophic accident, can you please elaborate on this.

God bless

Gunplummer

New member

If it is a massive screwup, enough to split the receiver ring, then the bolt will probably come back. I am not saying leave the rifle, but it will back up. This was proven in tests by P.O. Ackley. Most rifles will handle overloads, blocked barrels, blown primers. Some of the worst cases are wrong ammo. That is asking a lot from a rifle and the results can be hit or miss as far as end result.

**Mausers are low carbon steel. You can grind the thin case off and re-heat treat until you pass out and they will not reharden without adding carbon. I am not really a student of Mausers, but allegedly there was one model made from tool steel. This was the Chech or the the Polish model. According to rumor, there was a royalties fight between Carcano and a Mauser producer over a steel recipe. It may have been a special model. Someone else on here may know.

**Mausers are low carbon steel. You can grind the thin case off and re-heat treat until you pass out and they will not reharden without adding carbon. I am not really a student of Mausers, but allegedly there was one model made from tool steel. This was the Chech or the the Polish model. According to rumor, there was a royalties fight between Carcano and a Mauser producer over a steel recipe. It may have been a special model. Someone else on here may know.

Smoke & Recoil

New member

Side note/question about the actual bullet diameter...are you sure

about the proper bullet diameter of your 8x57 ?, as in 8x57S (.323)

vs 8x57J (.318).

about the proper bullet diameter of your 8x57 ?, as in 8x57S (.323)

vs 8x57J (.318).

Lug setback on an old Mauser means that headspace will continue to grow with every trigger pull.

Lapping the lugs also laps the lug recesses, and you've worn away the case hardening on both the bolt and receiver, which will make lug recess deformation only go that much faster.

You can handload down to low pressure rounds which will extend the life of the reciever, but the only real solution is to have the action and bolt gas carbeurized to restore the case hardening.

Jimro

Lapping the lugs also laps the lug recesses, and you've worn away the case hardening on both the bolt and receiver, which will make lug recess deformation only go that much faster.

You can handload down to low pressure rounds which will extend the life of the reciever, but the only real solution is to have the action and bolt gas carbeurized to restore the case hardening.

Jimro

I don't know about a catastrophic failure of both front lugs, but the safety lug on a Mauser 98 definitely will hold for normal shooting of service ammo.

I once was asked to check out a late war Mauser (Czech, IIRC) and found that the front lugs did not bear at all. There was no contact and no evidence that there ever had been. The safety lug was the only thing keeping the bolt locked. Yet the rifle passed the gauge tests. Further, it had obviously been fired extensively, though the owner, the vet who brought it back, said he had not fired it very much.

The safety lug and seat showed no setback and, as I said, the headspace was good; cases showed no sign of stretching.

Jim

I once was asked to check out a late war Mauser (Czech, IIRC) and found that the front lugs did not bear at all. There was no contact and no evidence that there ever had been. The safety lug was the only thing keeping the bolt locked. Yet the rifle passed the gauge tests. Further, it had obviously been fired extensively, though the owner, the vet who brought it back, said he had not fired it very much.

The safety lug and seat showed no setback and, as I said, the headspace was good; cases showed no sign of stretching.

Jim

James K is correct, it is entirely possible to get good headspace with only the safety lug engaged. When you have a pile of rifles and a pile of bolts, it is easier to just try swapping the bolts until you find on that has correct headspace than any other method for getting the rifles "re-arsenaled" and ready for sale.

Properly set up, the safety lug has a few thousandths of clearance and no contact with the lug recess.

But, since the OP is experiencing lug setback, the safety lug still has clearance to allow the setback to happen.

Jimro

Properly set up, the safety lug has a few thousandths of clearance and no contact with the lug recess.

But, since the OP is experiencing lug setback, the safety lug still has clearance to allow the setback to happen.

Jimro