I think thats advice to listen to over all the other internet BS

INTERNET BS!?!? Excuse me, but I have been lowering the hammer on a revolver the way I illustrated it since I bought my first Cap & Ball revolver in 1968. You can do the math on how long that has worked for me. Internet BS my eye!

Did anybody notice there is no firing pin on the hammer in that S&W manual? Try doing that sometime with a traditional revolver that has the firing pin in the hammer. Not very convenient, and it would probably be painful.

Here are a few photos that may be useful to this discussion. At the top of this photo is the hammer from a S&W Military and Police revolver made around 1917. Compare the profile of the hammer to the modern profile on a Model 14-3 made in 1973.

Here is a photo of the two hammers showing more detail.

Admittedly, the knurling on the older hammer is not very deep. On an old gun with a lot of wear the knurling can be almost worn away. Now compare that to the configuration of the newer hammer. This is a typical short throw hammer that S&W has been using ever since shortly after WWII. Not only is the knurling incredibly deep and sharp, there is a deep hollow between the hammer spur and the main body of the hammer. This hammer was designed specifically to help eliminate the thumb slipping off the hammer. With the older style, if your hands are sweaty it is feasible that the thumb could slip off the hammer, allowing it to fall. With the newer design, you would have to work at it for that hammer to slip out from under your grasp. That deep hollow is there so the tip of the thumb can roll into it as the hammer is lowered. Your thumb never looses contact with the hammer. I can lower a hammer like this on the hottest, sweatiest day with no problem at all.

Here is the MIM hammer on a modern S&W Model 617. Same basic design, deep knurling and a deep hollow in front of the hammer spur.

Now let's look at a couple of Colts. The top one in this photo is an Army Special made in 1921. The one at the bottom is an Official Police (essentially the same model as the Army Special) made in 1963. Notice the difference in the two profiles.

Here are the same two revolvers showing more detail. The older Colt has a hammer profile very similar to the older Smith. The newer Colt also has a deeper gullet in front of the hammer spur, and deeper cut knurling. Again, designed so the thumb is less likely to slip off the hammer even on a hot sweaty day.

My point is, once you have learned how to lower the hammer on a revolver with one hand, particularly if it is a relatively modern gun, there is little chance your thumb is going to slip off the hammer. And you should be pointing it in a safe direction anyway, right?

************

Yes, I learned how to lower the hammer on a revolver after watching Matt Dillon do it hundreds of times on TV. And Maverick, Roy Rodgers, Hoppy, Cheyenne, Sugarfoot, Wyatt Earp, and I don't remember who else. When I bought that C&B revolver back in 1968 it took about five minutes to perfect lowering the hammer without loosing control of it. Same thing with my Dad's Winchester Model '06 that I had been shooting even longer. It is not difficult. And I agree with DPris, it is simpler and requires fewer fine motor skills to learn to do it with one hand than to try to learn how to do it with two hands.

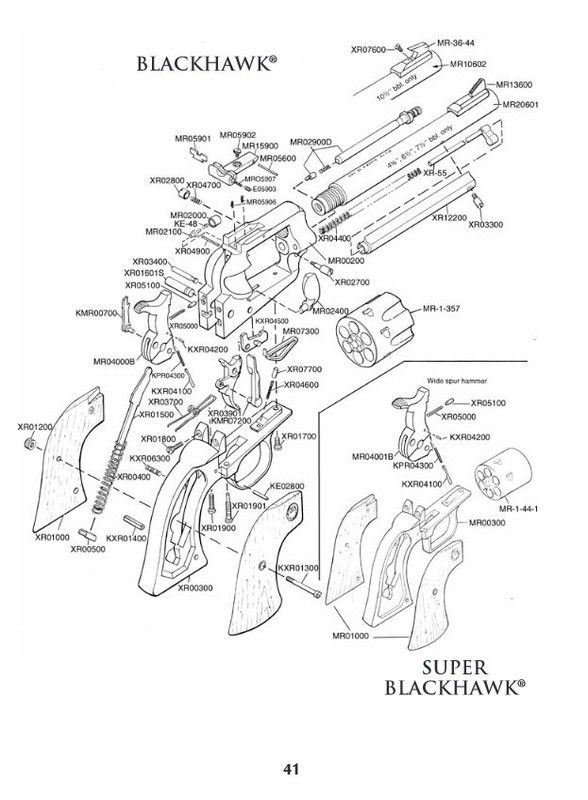

Regarding defeating the transfer bar on a Ruger, of course the transfer bar is defeated if you hold the trigger back. But I am not in favor of learning one technique for Smiths and Colts, and another technique for Rugers. Pulling the trigger and lowering the hammer works just fine for all of them. One simple technique for all.