marklmurray

New member

You should have posted a before shot. The after shot looks very sweet. Nice job!

Thanks! Yeah, I always forget the 'before' pics until 'after'. Then it's too late!

You should have posted a before shot. The after shot looks very sweet. Nice job!

Wow - wish I had your level of talent. Also wish I had gone to a gunsmithing school when I was young. Nice to know that there are fellas like you who still learn, master and pass on the skills. Great work.

I am not afraid to learn new skills and try new techniques. I sometimes gump things up, and when I do, I kick myself, but I don't do the same mistake again.

There are some guns I own that I bought only because I wanted to tinker with them, or simply open them up and see how they function.

Not bad, at all, for the average consumer-grade digital camera, even better for a phone.Well, I have to give credit to the old Droid X2 for the color representation!

Carding wheel?marklmurray said:The single most helpful accessory for the process, for me, was a carding wheel from Brownells. I chucked it in my drill press on the lowest speed and it really speeds things up. I still need to get into those nooks with the brushes or steel wool, but that's all you'll need the little ones for. The carding wheel got almost 100% of the cylinder each time, too.

I recently bought a Dan Wesson 22, and decided to replace the springs. Unlike some guns out there, I could not find much documentation on disassembly, although I have an older book with a few pages of instructions. Anyway, I took it down, and replaced the springs. Putting them back together is always the hard part. Took me about an hour, going slow, fitting parts, getting the springs in. I get to the end, and the gun will not function in double action.The first time I disassembled and rebuilt a carburetor, the results were not impressive. Had two tiny pieces left over - never a good thing.

Indeed it does. Thanks.marklmurray said:Aguila,

Luckily, it was still in my past orders: 360-164-631WB

Hope it helps!

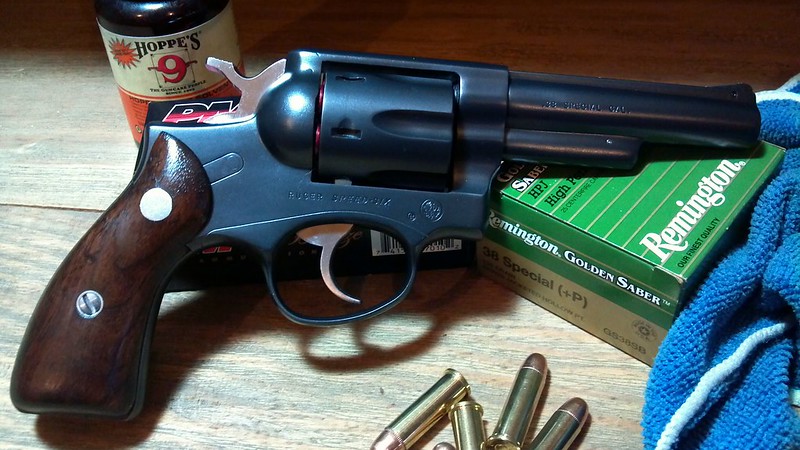

marklmurray, die you re-blue the H&R? from your picture it looks new.

Did you use Brownells rust bluing juice, or some other product?