You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Labeling reloads

- Thread starter kmw1954

- Start date

walnut1704

New member

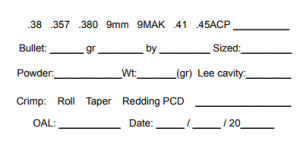

I went to Avery.com and made up my own label, and printed them up on Avery 58163 labels. These have removable adhesive so they don't mess up your boxes. You can export your design to a PDF on your hard drive. When done, I'll peel the label off the box and paste it in a notebook, with notes.

Mine look like...

Mine look like...

Attachments

Quote: "Looking to see how everyone else does it.

I do have a printed label tat I put inside my reload boxes that is pretty standard with Date, cal., powder type, powder weight, bullet type and weight, primer and OAL."

I am with you. My label lists, date, bullet, primer and powder.

I do have a printed label tat I put inside my reload boxes that is pretty standard with Date, cal., powder type, powder weight, bullet type and weight, primer and OAL."

I am with you. My label lists, date, bullet, primer and powder.

The actual label I use, which isn't the issue, is made from a Spread Sheet and printed on card stock in a lazar printer and cut to fit the inside of a Berry's plastic ammo box. No adhesive, no tape. They fit in with friction. Print is big enough to read thru the plastic, Very easy to change out. I also have these Berry's ammo boxed in 4 colors so I do color code them a bit also.

Masking tape and a red sharpie. Peels off easy when you reload that box. I WILL SAY THIS, the biggest mistake I've made in reloading over the years, ( started in 1972) is NOT KEEPING GOOD RECORDS. As I get older I just can't remember all my pet loads anymore . hdbiker

Last edited:

Smoke & Recoil

New member

I do not HOTROD my loads, I load for fun, so I only mark my containers

as the caliber. It gives me peace of mind knowing that my kids, grandkids and

great-grandkids, etc, can shoot them safely in the future. This method works

for me...mark as caliber only.

as the caliber. It gives me peace of mind knowing that my kids, grandkids and

great-grandkids, etc, can shoot them safely in the future. This method works

for me...mark as caliber only.

Putting more thought to this  This goes to the disc type powder measures because they should in theory ALWAYS throw the same charge weight of powder because the volume of the cavity never changes . I got to think about something Unclenick and others have brought up in the past . That is the density of the powder and how that changes from time to time do to moisture/humidity causing the powder to change in weight .

This goes to the disc type powder measures because they should in theory ALWAYS throw the same charge weight of powder because the volume of the cavity never changes . I got to think about something Unclenick and others have brought up in the past . That is the density of the powder and how that changes from time to time do to moisture/humidity causing the powder to change in weight .

There has been multiple instances or people leaving there powder measure set the same for a particular powder they throw all the time . How ever it does not always throw the same weighted charge . One day or even for weeks it throws a consistent charge then one day it starts throwing heavier or lighter charges and yet nothing has changed . Same powder , same setting on the powder measure that has not been moved .

So why has it changed and does that effect "volume" of powder ??? Just because it weighs more does it mean you actually have more powder thrown ??? Does more weight always mean more powder ???

My point to this to bring it back to the original question in the OP is if you have a fixed powder reservoir can you expect the same volume of powder each time over a looooong period of time ( lets say a small ball powder for this example ) . If it does change do to humidity ( which I believe it does ) does that change the volume allowed in to the reservoir resulting in higher or lower pressures ? ( just making numbers up ) Example- lets say the reservoir holds 1000 kernels of powder and when dry that weighs 10gr . Now that same 1000 kernels after absorbing some moisture now weighs 10.5gr .

1) does that 10.5gr still fit in that same fixed reservoir ?

2) does that new 10.5gr of powder still act like it's only 10gr when fired ??

There has been multiple instances or people leaving there powder measure set the same for a particular powder they throw all the time . How ever it does not always throw the same weighted charge . One day or even for weeks it throws a consistent charge then one day it starts throwing heavier or lighter charges and yet nothing has changed . Same powder , same setting on the powder measure that has not been moved .

So why has it changed and does that effect "volume" of powder ??? Just because it weighs more does it mean you actually have more powder thrown ??? Does more weight always mean more powder ???

My point to this to bring it back to the original question in the OP is if you have a fixed powder reservoir can you expect the same volume of powder each time over a looooong period of time ( lets say a small ball powder for this example ) . If it does change do to humidity ( which I believe it does ) does that change the volume allowed in to the reservoir resulting in higher or lower pressures ? ( just making numbers up ) Example- lets say the reservoir holds 1000 kernels of powder and when dry that weighs 10gr . Now that same 1000 kernels after absorbing some moisture now weighs 10.5gr .

1) does that 10.5gr still fit in that same fixed reservoir ?

2) does that new 10.5gr of powder still act like it's only 10gr when fired ??

Guess this goes back to my original question, volume vs. weight vs. consistency. Whether it be with dippers or a fixed disk the volume/weight can only change with the consistency of the powder granules. For instance I have found the granule size has been very uniform with both the AA#5 and the Ramshot while the HP=38 granule size varied.

So with the HP-38 I am consistently getting charges that can vary buy 0.01gr over the course of 50 drops. I attribute this to the powder and not to the measure or the procedure used. Granted, 0.1gr isn't much when the target is 20.0gr but when the target is only 3.0gr then 0.1gr is a much higher percentage.

Being as stated that the volume of the disk or dipper cannot change without a change in the powder, because of inconsistent granule size and how it fills the space, moisture, static electricity or whatever.

The question again seeing as this thread is continuing is simple and specific.

When the charge weight is inconsistent how would you mark the weight? The low weight, high weight or as it to me is just a reference point mark the Disk cavity or dipper size?

At present I am leaning towards marking the Disk cavity because that is a constant that will not change and is well within the parameters that I am looking for regardless of the actual weight.

So with the HP-38 I am consistently getting charges that can vary buy 0.01gr over the course of 50 drops. I attribute this to the powder and not to the measure or the procedure used. Granted, 0.1gr isn't much when the target is 20.0gr but when the target is only 3.0gr then 0.1gr is a much higher percentage.

Being as stated that the volume of the disk or dipper cannot change without a change in the powder, because of inconsistent granule size and how it fills the space, moisture, static electricity or whatever.

The question again seeing as this thread is continuing is simple and specific.

When the charge weight is inconsistent how would you mark the weight? The low weight, high weight or as it to me is just a reference point mark the Disk cavity or dipper size?

At present I am leaning towards marking the Disk cavity because that is a constant that will not change and is well within the parameters that I am looking for regardless of the actual weight.

Checking charges is something I do w/o even thinking about it. It's just part of my routine.

I can understand your thought on volumes and densities. When I first received my disk measure I only had one powder in the house, HP-38. So I took the time to get familiar with it and started dropping test samples from each cavity and recording them. I believe I did about 25 in each one and was amazed at how consistent they were and noted the high and the low and also the average. I then noted it in my logbook. A few months later I came into a second measure so I did the same thing as before and when I went back to compare there was quite a discrepancy. So I brought out the old one and double checked it against what I found previously. There was a difference. WoW was all I could say. Same measure. exact same powder from the same container with 2 different results a few months apart.

I check weigh many more charges than I believe most do. Yes it slows me down but I have nothing but time. It also gives me peace of mind.

I can understand your thought on volumes and densities. When I first received my disk measure I only had one powder in the house, HP-38. So I took the time to get familiar with it and started dropping test samples from each cavity and recording them. I believe I did about 25 in each one and was amazed at how consistent they were and noted the high and the low and also the average. I then noted it in my logbook. A few months later I came into a second measure so I did the same thing as before and when I went back to compare there was quite a discrepancy. So I brought out the old one and double checked it against what I found previously. There was a difference. WoW was all I could say. Same measure. exact same powder from the same container with 2 different results a few months apart.

I check weigh many more charges than I believe most do. Yes it slows me down but I have nothing but time. It also gives me peace of mind.

"When the charge weight is inconsistent how would you mark the weight? The low weight, high weight or as it to me is just a reference point mark the Disk cavity or dipper size?"

I use a powder measure. It is the Lyman with three slides. It can be set up for a small amount of pistol powder to a large charge for a large rifle cartridge. Yes, the weight of the thrown charge may vary a bit depending on the powder, but I don't worry about it. I don't load to full max anyway and figure a little this way or that is not going to matter.

I use a powder measure. It is the Lyman with three slides. It can be set up for a small amount of pistol powder to a large charge for a large rifle cartridge. Yes, the weight of the thrown charge may vary a bit depending on the powder, but I don't worry about it. I don't load to full max anyway and figure a little this way or that is not going to matter.

There is also some to be said about how you operate the powder measure. I have had some say handle up (this is where it fills) bump the knocker to make sure the cavity is full then handle down to dump.

I prefer to go handle up, wait half a second for the cavity to fill then handle down to dump, then hit the tapper to make sure it all dumped. And when the measure is half full, full it up again. It seems to make a bit of diff how much powder is in the measure. IOW it will dump a bit less as the powder drops in the measure.

Any way I am happy with whatever the measure drops, I am not one to weigh each charge.

Oh, if you change to a new container of powder, always check weights as I have found the powder may vary a bit from batch to batch even with the same type and name on it.

Sorry, this thread was about labeling and ends up about powder measures. Hmmm guess we need to stick to the subject?

Anyway: Date, Bullet type and weight, Powder type and weight, Primer type and brand, are what need to be put on the label.

I prefer to go handle up, wait half a second for the cavity to fill then handle down to dump, then hit the tapper to make sure it all dumped. And when the measure is half full, full it up again. It seems to make a bit of diff how much powder is in the measure. IOW it will dump a bit less as the powder drops in the measure.

Any way I am happy with whatever the measure drops, I am not one to weigh each charge.

Oh, if you change to a new container of powder, always check weights as I have found the powder may vary a bit from batch to batch even with the same type and name on it.

Sorry, this thread was about labeling and ends up about powder measures. Hmmm guess we need to stick to the subject?

Anyway: Date, Bullet type and weight, Powder type and weight, Primer type and brand, are what need to be put on the label.

Last edited:

Same measure. exact same powder from the same container with 2 different results a few months apart.

Ok we are on the same page and is why I don't like the disc type measures . I still recommend you get the charging bar upgrade for the Lee auto disc . That way you just write the actual intended charge and you check weight it every time there after .