Looking to see how everyone else does it.

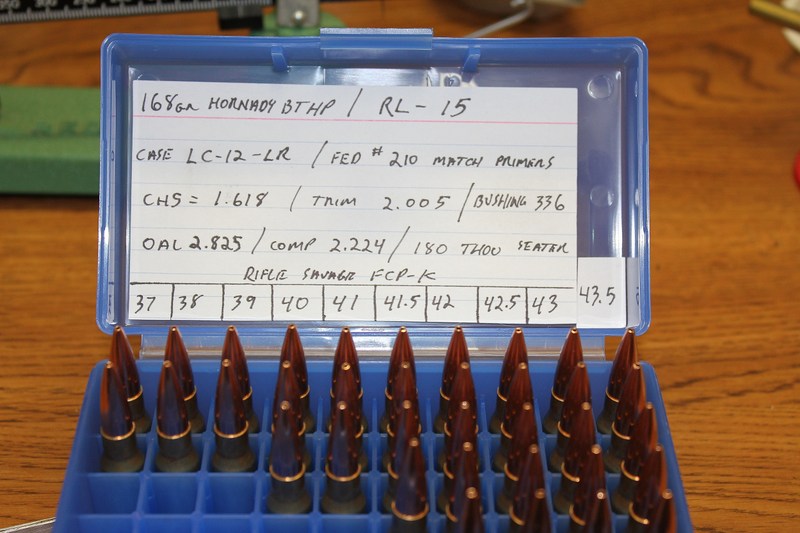

I do have a printed label tat I put inside my reload boxes that is pretty standard with Date, cal., powder type, powder weight, bullet type and weight, primer and OAL.

My real question is with the powder weight. I charge with a Lee powder measure, either the Drum or the Disk but mostly with the Disk measure. Now with the powders I'm using I find I get a variance of about 0.1gr., so say this using cavity #40 it will consistently drop between 4.1 and 4.2gr equally which I can live with for my pistol loads.

So how would you label the weight? I've started just using the volume reference and the weight which I think is too much info.

I do have a printed label tat I put inside my reload boxes that is pretty standard with Date, cal., powder type, powder weight, bullet type and weight, primer and OAL.

My real question is with the powder weight. I charge with a Lee powder measure, either the Drum or the Disk but mostly with the Disk measure. Now with the powders I'm using I find I get a variance of about 0.1gr., so say this using cavity #40 it will consistently drop between 4.1 and 4.2gr equally which I can live with for my pistol loads.

So how would you label the weight? I've started just using the volume reference and the weight which I think is too much info.