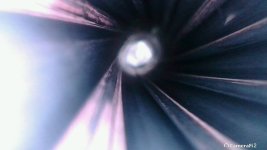

The photo is incredible. Shooting lead down it would be dreadful! I'm not even certain how they could make a barrel like that! I have an off-the-shelf Model 686 and it's perfect. That you should have a Performance Center gun with those problems males me glad I didn't have a gun those guys screwed up! Weren't they supposed to make S&W guns

better?

Getting them on the phone sounds like a good idea. The idea is to make them send you a fabulous gun in return and get them to inspect the damn gun before returning it. And for that you need a commitment from a manager.

Smith & Wesson is one of the best gun makers of

Smith & Wesson is one of the best gun makers of

all time, and, in its prime, also made some of the

world's most beautiful revolvers. This 629 was

virtually perfect, and it was flawless!

Surely the Performane Center has a manager. And he's the one you need to talk to. If you've sent the gun in twice, they should certainly feel a certain amount of shame o over the matter. I remember one time I bought a beautiful stainless steel Virginia Dragoon. Not a fancy gun by any standards. The first time I shot it, second shot, the hammer crystallized and shattered like glass. It was just a screw-up of the metallurgy. The thing I remember was how nice the people were at Interarms. I drove to their place in Alexandria, Virginia, and they fixed it for me overnight. Can't imagine an expensive gun at the S&W Performance Center! I world expect them to be

very apologetic, especially with a barrel that looked and sounded like a zipper!

I'd send the photo first, then talk to the PC manager. Then I'd ask him what I was looking at, and how a barrel could be manufactured like that! I've bought a lot of S&W guns and most of them were perfect. Even the autos. The first generation autos were astoundingly bad and gave the company a black eye, but my second and third generation guns were great. The only issue was on a 659 9mm model. The backside of the gun, on top, was uneven, and was a bit higher on the left than the right; however, it shot reliably, and accurately. It was just unsightly. And it was one of my favorite guns. I owned two others of the same model. Still do. But I got rid of it and kept the other two. Just found it distracting.

Please let us know what happens. I hope they make things right.

--