stagpanther

New member

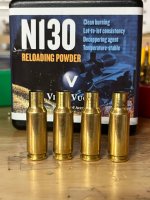

Rifle is assembled--but I'm dead in the water; I've ordered the necessary neck bushings--in fact I ordered the same size bushings from multiple vendors all of whom said they were in stock but none of whom has packed and shipped them as of yet. The barrel I got was cut to Robinett's specs; the chamber neck being .330 and case length specified as 1.510. The design is intended to have a precise neck tension and bore engagement right from the start upon chambering. I've struggling with the mathematics of the thing--it's not quite as simple as adding up the various components because there is no 30 BR brass--you have to neck up either 6 or 7 mm brass; and of those two only 6mm BR is generally available. That's a pretty big jump and the brass is going to flow in such a way that I haven't been able to get precise consistency through the entire length of the neck to shoulder; I've ended up with external doughnuts at the neck/shoulder junction and that will stop the case from fitting the chamber. The trick (apparently from what I've read) is to get the brass sized well enough to get a first fire-forming shot. I know what you're thinking--just turn the neck, and I do have the turning equipment to do it--but I want to avoid removing brass if at all possible. I have smaller 308 bushings--but I think for this particular chambering assuming typical neck thickness of .012 to .02 the necessary bushings are going to be in the range of .327 to .329. As far as I know there is no "one pass" 30 BR sizing die, I guess because the brass is meant to be form-fitted to a particular chamber.