I recall buying an older Redfield collimator off youtube.Never usd one.Figured I could use it for something.

I got it out,tried to use it.

Understand,I know how to use a plug gage in a precision hole.Its pretty near a thumb and forefinger grip on the gage.I expected the same from the spuds provided with the boresighter.

What I tried was too tight.I stopped and put it away.No harm done.

When you bought your rifle,did the shop install the sight and bore sight it for you?

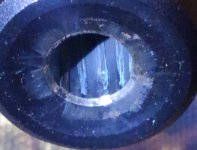

I do not know what did that to your barrel,but to my eye,it does not look like it was caused by any barrel making process I recognize.

It COULD be caused by a counter clerk who got a boresight spud stuck and twisted it to get it out. I'll look closer.

I won't even say it did not happen at Remington.But I'm skeptical it did.

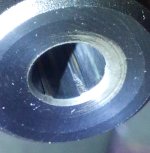

Rem patched it for you.Not the best.But others had custody of that rifle after it left Remington.

Update,I looked again. Somehow,there is another part to this story.Initial pic,before going to Rem,the other lands look washed out.

The edge chamfer looks machine done,concentric,and undamaged.

The damage is not spaced uniform,like power feed.The track of the damage is not in line with the linear traver of any tool rifling or boring.

The damage only crosses one land.It did not travel around the bore,as any broken machine cutter would.

It almost looks like a renegade dremel skittered...but not really.Those usually get traction and would have deflected.I don't think that's it.It also looks more like deformation than cut.

It looks like something freak,like someone working on a ladder over the rifle rack dropped his drill motor,or someone put a screw through a crate in the wrong place.It looks like the muzzle got hung on the head of a drywall screw.

If a borescope says the rest of the barrelis good,I'd cut it an inch or inch and a half

The more I look at it,the more it looks like the muzzle was pressed against a board and someone drove a screw into it. A small screw.The threads tracked down that land.You can see puckered up displaced metal at the edge of each mark,like a crater rim.

How or why that happens? No clue.

I had a horrible experience pulling the rear main seal out of a5.0 liter Ford V-8

Its done by driving a sheet metal screw into the seal and using the screw to pull the seal.I left a mark like that in my crankshaft.I put aJiffy -Sleeve over it.Still running.