You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Faster Burning Powder for Shorter Barrel?

- Thread starter 3006loader

- Start date

- Status

- Not open for further replies.

MarkCO said:I am done with this one. Way too much ignorance regarding combustion processes on here. No matter what you think you know, can't beat Pv=nRT.

Quote:

"burnt" powder igniting when they enter an oxygen rich envioronment

Completely absurd.

From John Barsness of Handlaoder Magazine when asked what are the causes of Muzzle flash in a rifle round.

"All the powder that's going to burn, burns within the first few inches in front of the chamber. How much of it burns depends on the powder, pressure, etc. Rarely does it all burn, but 99+ percent can.

Flash is caused by hot gas reigniting."

And This absurd article.

https://legallyarmedamerica.com/2014/01/10/muzzle-flash-what-is-it-and-what-causes-it/

Muzzle flash can be broken down into five distinct components:

1) Muzzle glow is a reddish glow that is visible before the bullet leaves the barrel. Muzzle glow is created by superheated gases that have leaked past the projectile and have exited the barrel.

2) The primary flash is caused by propellant gases exiting the firearm behind the bullet. Although amongst the brightest of the flashes, the heat of the primary flash dissipates quickly and thus is no longer visible.

3) The intermediate flash is caused by shock waves created by the high speeds of the escaping gases and projectile, and appears as a reddish disc shape in front of the muzzle.

4) The secondary flash appears farthest from the muzzle as a large white or yellow flame. Secondary flash is caused by the mixture of fuel-rich gases and oxygen in the atmosphere surrounding the muzzle.

Last edited:

Here is an actual test with progressively shorter barrels, from 22 inches down to 10 inches.

http://www.accuratereloading.com/223sb.html

As you can see the fastest powder H-4198 had the slowest velocities over the slower powder 322 and N135 in every barrel length and at no time did the fastest power (4198) out perform the slowest N-135.

http://www.accuratereloading.com/223sb.html

As you can see the fastest powder H-4198 had the slowest velocities over the slower powder 322 and N135 in every barrel length and at no time did the fastest power (4198) out perform the slowest N-135.

I'll just leave this here for reference...

Engineering Design Handbook, Interior Ballistics of Guns, USArmy Materiel Command, published February 1965.

Section 1-9.3 PP3.

The rapidity with which a propellant will burn depends upon the chemical composition, pressure, and area exposed to burning. The quickness of a propellant is a relative term only, expressing its rate of burning compared with others. A quick propellant will burn more rapidly and produce a higher pressure in a given gun than a slow one. Propellant of fixed weight, chemical composition and grain geometry may be made quicker by decreasing size, thus increasing burning area.

Engineering Design Handbook, Interior Ballistics of Guns, USArmy Materiel Command, published February 1965.

Section 1-9.3 PP3.

The rapidity with which a propellant will burn depends upon the chemical composition, pressure, and area exposed to burning. The quickness of a propellant is a relative term only, expressing its rate of burning compared with others. A quick propellant will burn more rapidly and produce a higher pressure in a given gun than a slow one. Propellant of fixed weight, chemical composition and grain geometry may be made quicker by decreasing size, thus increasing burning area.

MarkCo I think you're forgetting there is something in the way of the powder keeping it from expanding . That is the bullet . You will blow up your gun before you get 4198 to push a 200gr bullet faster then 4350 in a 308 .

Now on paper you might be right that a faster powder can get equal to faster velocities . How ever it will never do it safely in a firearm .

I hope Unclenick comes along to help explain . If not here's a couple things he's wrote in the past about burn rates

Now on paper you might be right that a faster powder can get equal to faster velocities . How ever it will never do it safely in a firearm .

I hope Unclenick comes along to help explain . If not here's a couple things he's wrote in the past about burn rates

The slower the powder the more charge weight you need to achieve a specific peak pressure. This is because the bullet has time to get further down the barrel before the pressure peaks, so the peak is occurring in a larger volume than a faster powder peaks in. The exceptions have to do with energy content of the powder formulation. Exceptions: If you are comparing two powders with different energy content per unit weight and the faster one is the one with lower energy content, then the slower ones charge may not be lighter. Difference in energy is usually comparing a single base powder to a double base powder, as the nitroglycerin usually used in the latter has a 3.52% surplus oxygen balance it contributes to help offset the oxygen deficit normal to nitrocellulose combustion and that varies with the nitrocellulose species (mono-, tetra-, or hexanitrate) balance of the powder. Pure hexanitrate (ideal) has a -24.23% oxygen balance.

The larger the expansion rate, the faster the powder needs to be. A .45 ACP bullet doesn't have to move as far forward to double the volume the powder is burning in behind it as a 25-06 bullet does. In order to raise pressure as the bullet moves, the powder has to make gas fast enough to keep up. That's why a large expansion ratio tends to need faster powder than a small one.

The smaller the bullet sectional density, the faster the powder needs to be. The reason is the same as above—rate of expansion—but the mechanism differs. While a high and low SD bullet in the same cartridge will have the same force on their bases at the same pressure, the greater inertia of the higher SD bullet will cause it to take longer to accelerate under the force from that pressure. As a result, it keeps the space from growing as quickly, giving the powder more time to make the gas needed to keep the pressure up. Here I used SD instead of weight, so that different calibers could be compared. For the same caliber, obviously, SD and weight go up and down together.

For a given barrel length, overbore cartridges have the lowest expansion ratios and short powder column, straight or nearly straight wall cartridges have the largest expansion ratios, so the former can give a slow powder the most time to make gas to keep up with the growth in the pressure volume, while the latter give the powder the least time, assuming same-SD bullets.

Powder burn rates are determined under fixed conditions. Because chemical reaction rates increase with pressure, so does the actual burning rate of a powder in an actual cartridge rather than in fixed pressure laboratory conditions. As a result, a powder that is too slow to work well at a minimum load pressure and temperature will generally do better at higher pressure and temperature where it burns faster and therefore has an easier time keeping up with expansion. Thus, low pressure loads of slow powders tend to be dirty due to waste from incomplete combustion, while a fast powders can still burn fairly cleanly at a lower pressure and temperature.

Probably HS-5, HS-6, or HS-7. All older St. Marks spherical powders that are slower than the 231/HP-38 that is their powder that is popular for target loads. HS-6 is still available, and was once a popular full power factor powder, but Power Pistol and others have mostly taken its place. None of those HS powders is fast, and, in general, the slower the powder, the higher the pressure you have to run it at to get reasonably clean burning. Slow powder and low pressure don't go together for that and several other reasons.

_________________________________________________________________

Expansion and sectional density are the key things to understand. When the cartridge is assembled, there is a certain amount of volume under the bullet for the powder to start burning in. This is usually called the powder space. But once the bullet starts to move forward, the volume the powder is burning in grows behind the bullet as it moves. The shorter the powder space and wider the bullet, the less distance the bullet has to move to double the powder space, and if the pressure is to be maintained, the powder has to make twice as much gas by the time it gets there. If the pressure is to increase, it has to make more than twice as much gas by the time the bullet gets there. The faster the bullet moves, the faster the powder space doubles and the faster still the powder has to make gas if pressure is to be maintained or increased.

That brings us to sectional density. This is the other thing that affects how quickly the powder space can grow. Sectional density represents how much bullet mass each square inch of the bullet base has in front of it. Since the force applied to the bullet base to move it forward is the pressure divided by the number of those square inches of base, the less weight each square inch has in front of it, the less inertia that force has to overcome and the faster the bullet accelerates under that pressure.

So, if you have a bullet with a short powder space, and a wide bullet with low sectional density, it doesn't take much pressure to get the bullet scooting forward pretty fast, and you need a fast powder to make gas fast enough to keep up with that. Otherwise you have to settle for just burning powder real fast and accepting that pressure will drop off real fast as the bullet moves forward, expanding the powder space.

Both strategies are used, depending on whether the powder you use is digressive of progressive. Digressive powders like Bullseye and the very fast Vihtavuorin N310 or Hodgdon Clays, burn from the outside surface in, and the material burns equally fast until the grain is consumed. So it makes its gas as fast as possible and quits, and when that's done the pressure in the bore drops as the bullet moves forward. These powders are called digressive because, if you burn them in a special constant pressure vessel, the rate at which they make gas diminishes as the grain burns inward. That's because the burning surface area is getting smaller and smaller and the rate at which the burn eats the grain inward is constant in constant pressure.

Progressive burning powders do just the opposite. The longer they burn, the faster they make gas until they run out. There are a couple of strategies used to make this happen. With stick powders they put little tunnels called perforations inside each grain, then put a deterrent coating on the outside of the grain so the outside burns very slowly. But not the inside. So the flame spreads into the perforations where they burn from the inside out. That means the diameter of each tunnel keeps getting bigger, providing a bigger and bigger burning surface area that provides gas faster and faster until it runs out of tunnel wall material.

Spherical progressive powders have deterrent coatings that penetrate into their surface, becoming less concentrated as you go from the surface toward the center of the grain. This allows the outside surface to begin burning slowly, but speed up as it burns toward the center. In that way they can make gas faster and faster up to the point the remaining surface area is so small that even burning at its top rate it can no longer keep it up.

The idea behind the progressive powders is that because they start burning slowly, you can put a lot more powder in without making enough gas to created too much pressure when the bullet is just starting to move. As the bullet goes down the tube a progressive powder makes gas faster and faster, actually raising the pressure as the bullet moves and expands the space. It continues that way until it burns the bulk of the powder out. The slow burn start gives the bullet time to expand the chamber before a progressive powder has made all its gas. This means the pressure peaks in a larger total powder space, which takes more total gas than reaching the same pressure in a smaller space does. So, now as the bullet goes still further forward after the pressure peak, the pressure drops off less rapidly than it would if the pressure peak had been reached with less gas in a smaller space. In effect, by delaying the peak, progressive powders get more total space to peak in which lets a larger quantity of the powder be safely fired . This gives you more gas which keeps acceleration from dropping as quickly as the bullet moves beyond the the peak pressure point in the bore.

In real life it isn't quite that simple, but that's the general idea. Even a big charge of progressive powder in an overbore rifle can't keep up with bullet expansion for more than a few inches before pressure starts to drop. There are several reasons. One is just that the bullet has picked up around half its velocity by then, so it is running away and expanding the powder space really fast from that point forward, making it impossible for gas generation to keep up. Also, once the bullet is going really fast, it starts to challenge the speed with which the gas can flow forward after it, so a partial pressure drop develops between the chamber and the bullet base. Another factor is that the powder doesn't actually light up all at once. It normally starts at the flash hole and the flame front propagates forward, so the powder just behind the bullet gets lit later than the rest. This is why you find some unburned grains on the ground out in front of the firing line. The larger and slower you make the charge, the more of that you get, so there's a point where going further just makes for more unburned powder and the bullet doesn't go any faster or has actually lost velocity as compared to a faster burning powder charge. Such slow powder requires higher start pressures to help burn through deterrent coatings, and has a harder time achieving them. As a result, ignition becomes erratic and velocity variation increases.

Last edited:

steve4102 said:"All the powder that's going to burn, burns within the first few inches in front of the chamber. How much of it burns depends on the powder, pressure, etc. Rarely does it all burn, but 99+ percent can" John Barsness

MarkCO said:"The quickness of a propellant is a relative term only, expressing its rate of burning compared with others. A quick propellant will burn more rapidly and produce a higher pressure in a given gun than a slow one." USAMC

I can see how these statements could lead to some confusion. Barseness is correct that that most powders never burn completely. The idea that they do is a persistent belief even among some in the industry, but you can prove to yourself a couple of ways. A simple one Mark Humphreyville pointed out is that you can ignite the sweepings from in front of the firing line at any indoor range. They burn and flare like smokeless powder does in open air because there's lot of unburned powder in that dust. Another is to compare a very quick powder to a very slow one in a highly overbore chambering like a 22-06. You quickly figure out that it takes perhaps three times as much slow powder as of fast pistol powder to achieve the same peak pressure, and that, based on energy content of the charges, for both powders to have burned completely by their respective pressure peaks, the slow powder would have made so much more gas that the peak would be happening more than half way to the muzzle and that the pressure then wouldn't drop enough at the muzzle to prevent it distorting the bullet. (Laramore pointed out long ago that bullets leaving the muzzle at near high power rifle peak pressure are upset by the gas and, I would add, that gas cuting of the base would also be apparent on their bases.)

Regarding relative burn rate, it is assumed by many to apply accross the board. It doesn't. Relative burn rate is a result for a standard test under standard conditions. Start varying pressures and temperatures and the burn rate order changes. Moreover, its costs money to do that testing, so most burn rate charts just approximate it based on known load data, which is why no two such charts seem to agree exactly. The powder companies know the burn rate specs they provide their manufacturing contractors, so each powder makers relative burn rates for their own powders should be correct. But changing order under pressure is a natural result of the differences in powder burn characteristics.

Twenty-some years ago John Milosovich did a good experiment to show this. He made up loads for .308 Win using IMR4895 and IMR4064 behind 80 grain bullets. Instead of loading to matching pressures, he adjusted loads to get matching velocities at 2200 fps, 2300 fps, 2400 fps, 2500 fps to see how much powder that required. To reach 2200 fps it took less 4064 than 4895, indicating the 4064 was the faster powder at the pressures involved. At 2300 fps the differnce was smaller, but 4064 still appeared to be the faster powder. At 2400 fps the charge weights were the same within the 0.1 grain resolution of typical powder scales. At 2500 fps it took more 4064 than 4895, indicating the 4064 was now the slower of the two powders.

Differences in grain length and perforation count and size were likely responsible for that behavior. The differences get bigger as the differences in powder type become greater, such as when going from flake to stick to spherical, single-base to double-base, and some change for other additives and additive quantities. The point is, saying which powder is actually faster than another depends on the conditions and they change as you work a load up.

As to short and long barrel velocities, the differences are easy to see in the QuickLOAD model, which is a pretty good one from what I am able to discern. Assuming you achieve the same peak pressure for all powders you try, the powders that are fastest in that pressure range with peak soonest. Since bullet acceleration is greatest at the pressure peak, bullets fired with fast power start out faster than those fired with slower powders, but the pressure drops off pretty fast as the bullet moves forward, so acceleration (the rate at which additional speed is addes) slows quickly, too. Because of the greater amount of total gas the slow powder produces, pressure and acceleration drop off more slowly after the peak. As a result, even though the fast powder's bullet is going faster at first, past its own peak, the slow powder's bullet starts to catch up. Typically, it will pass the velocity of the fast powder a few inches past the peak.

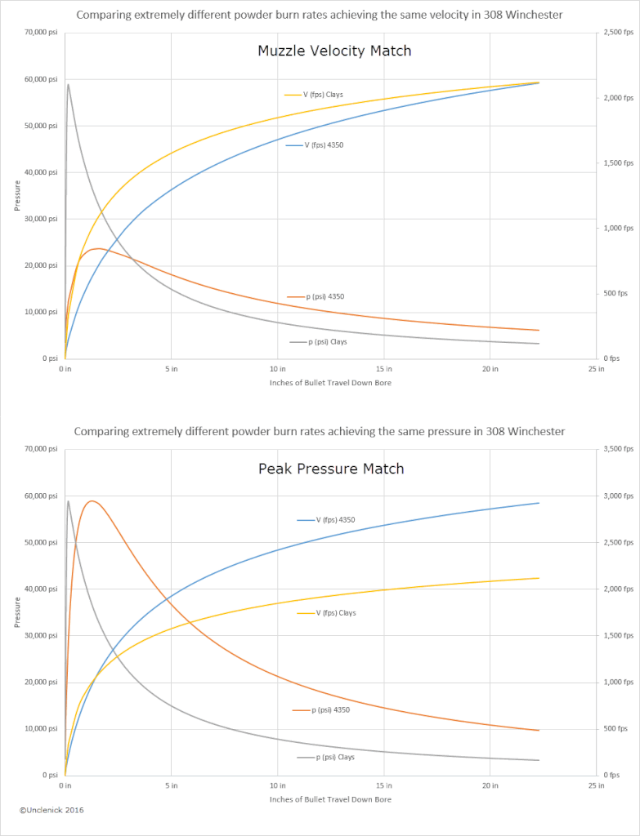

To make an extreme example, QuickLOAD's output for the bottom plot in the graph below, compares the super fast Hodgdon Clays with and and impossibly compressed load of IMR4350 in 308 Winchester with a 150 grain bullet in a 24" barrel. You'll note the traces plot bullet base travel in inches starting from its position in the loaded cartridge. In the bottom trace the Clays velocity (yellow trace) is higher right up until the bullet has moved about 2 inches, at which point the IMR 4350 velocity surpasses it. So, for any barrel longer than 2 inches, the slower 4350 load would produce more velocity, and you would have to cut the barrel down to below that length for the Clays to give you more velocity. You would then suffer Naramore's problem with your bullets.

But, that example is pretty extreme. The same bullet comparing IMR4198 and IMR4350 has the slower powder's velocity surpass that of the faster powder at about 8 inches, so, assuming the model prediction is accurate, you would have to cut a barrel down to eight inches or less to get faster 150 grain bullet velocities from 4198 in that model. Comparing 4895 to 4350, the powders are enough more similar that the numbers is swinging back the other way, with 4350 surpassing 4895 velocity at about 4 inches down the bore.

The computer model won't be dead on exact, but it shows the principles, and the actual barrel cutdown tests linked to earlier tend to verify it. Some people may not get the same result, but most don't cut barrels down to ensure the same chamber is involved with each shot and even if they did, it's likely most do not have the pressure testing equipment to adjust peak pressure to a actual match. Pressure signs don't work well for this as the appearance of them happens at different pressures depending on the speed of the firing event and how that influences the dynamics of the forces creating their appearance.

3006loader

New member

The amount of good information in this thread is equal or better to something someone would pay for.

Great info once again UN .

Thanks for correcting my blanket statement . You showed if you cut the barrel down enough the faster powder can push the bullet as fast if not faster .

My point with the 4198 and 4350 powders was really more to do with the heavy bullet . If not to much trouble . where does QL say the two powders cross paths with the heavier 200gr bullet or is it about the same ?

Me said:How ever it will never do it safely in a firearm .

Thanks for correcting my blanket statement . You showed if you cut the barrel down enough the faster powder can push the bullet as fast if not faster .

My point with the 4198 and 4350 powders was really more to do with the heavy bullet . If not to much trouble . where does QL say the two powders cross paths with the heavier 200gr bullet or is it about the same ?

Last edited:

A quick propellant will burn more rapidly and produce a higher pressure in a given gun than a slow one.

This is true, but you have to blend in the other part of the math which is, the faster the powder, the shorter the duration of the peak pressure spike.

The velocity of a bullet is directly proportional to the pressure produced, AND how long that pressure is applied.

FoghornLeghorn

New member

Thread resurrection for content relative to my powder selection.

jetinteriorguy

New member

Oops, I missed the thread resurrection. My comment not needed.

FoghornLeghorn

New member

Yeah, because of the pandemic/shortages I've been stocking up on powders I've never used. This thread has much relevant data.

We can change one variable,measure results,and jump to conclusions.

It can be that simple,sometimes. But often,it is not that simple.

A conclusion about barrel length versus burn rate might not be true across the board for 30 carbine,308,and 300 Rem Ultra mag.

Conclusions drawn from sawing an inch at a time off the barrel of a 308 using a 200 grain bullet may or may not hold true with a 150 grain bullet.

Run the same series of tests using a 30 carbine or 30-06 or 300 Rem Ultra Mag and your cause vs effect "rule" may or may not hold true.

Two dimensional thinking does not always ring true when changing one thing might actually change six other things.

I have a single shot 14 in bbl handgun in 260 Rem. Using 120 gr bullets,I got best results with the RE-15,Varget,4895 range of powders.

I don't have a rifle in .260, but I suspect with a 22 in bbl I'd get more performance with powders in the RE-19, 4350 ,range. But I can't say I know that until I load them and chrono them. I've been wrong before.

It can be that simple,sometimes. But often,it is not that simple.

A conclusion about barrel length versus burn rate might not be true across the board for 30 carbine,308,and 300 Rem Ultra mag.

Conclusions drawn from sawing an inch at a time off the barrel of a 308 using a 200 grain bullet may or may not hold true with a 150 grain bullet.

Run the same series of tests using a 30 carbine or 30-06 or 300 Rem Ultra Mag and your cause vs effect "rule" may or may not hold true.

Two dimensional thinking does not always ring true when changing one thing might actually change six other things.

I have a single shot 14 in bbl handgun in 260 Rem. Using 120 gr bullets,I got best results with the RE-15,Varget,4895 range of powders.

I don't have a rifle in .260, but I suspect with a 22 in bbl I'd get more performance with powders in the RE-19, 4350 ,range. But I can't say I know that until I load them and chrono them. I've been wrong before.

Reloader270

New member

Once you have cut it off, you cannot weld it back. Rather go for a 22" barrel. Not too long and still excellent for hunting.

Dispense1710

New member

Bringing it back because it is great. I hope the many contributors to this thread are still active here and look forward to learning more from you all.

Marco Califo

New member

Rather than mess with whatever you were dangerously thinking, the way to increase velocity is to step down bullet weight.

Published data is good. Thinking too much when you are not the industry expert is WHACK.

Published data is good. Thinking too much when you are not the industry expert is WHACK.

Marlocalifo

Once again, jumping to a conclusion over changing one variable can be misleading. That one variable may indeed have the expected effect. A lighter bullet would be faster....at the muzzle.

But heavier bullets often have better Ballistic Coefficients.

Compare the highest velocity loads you can find for a 338 Win Mag launching a 300 gr MatchKing.Maybe 2500 fps?

Now find the hottest lighter bullet load for a 7mm Rem Mag. Maybe up to 150 gr. Over 3000 fps. Maybe 3200? I'm guessing .

Run them through ballistic software out to 1000 yds. You might be surprised.

Regardless what you find, my point is changing one variable often changes other variables.

Once again, jumping to a conclusion over changing one variable can be misleading. That one variable may indeed have the expected effect. A lighter bullet would be faster....at the muzzle.

But heavier bullets often have better Ballistic Coefficients.

Compare the highest velocity loads you can find for a 338 Win Mag launching a 300 gr MatchKing.Maybe 2500 fps?

Now find the hottest lighter bullet load for a 7mm Rem Mag. Maybe up to 150 gr. Over 3000 fps. Maybe 3200? I'm guessing .

Run them through ballistic software out to 1000 yds. You might be surprised.

Regardless what you find, my point is changing one variable often changes other variables.

Dispense1710

New member

I was thinking about gaining knowledge, which is certainly less dangerous than ignorance. And I use fast powders in my 10" 458x2. Thanks for you're concern though.

- Status

- Not open for further replies.