Due to picture limitations per post, I am having to break this up into multiple posts:

Far more critical than claw extractors is cartridge orientation, timing, and release from the magazine. If this discussion were a discussion of M1911 magazines everyone would understand. There are all sorts of M1911 magazines with different shaped feed lips, rounded or flat followers, all of which attempting to orient the 45 ACP round, align it at the proper angle and just release it at the correct moment. When you get a magazine that does not do that correctly, your gun becomes a jam a matic. When you get a balky magazine you can bend and tweak the lips on the thing, and it may work for a while, but eventually, it goes bad. Relying on thin sheet metal for 100% feed has its risks.

Early bolt actions had milled integral feedlips. This was true of pre 64’s, but I am not uncorking one of those to get a picture. Feed lips were machined as a part of the receiver. As long as the receiver was properly machined, these integral feed lips provided the most precise, repeatable, and rugged cartridge feed and release of any type of feed mechanism. However, the feed lips had to be matched to the cartridge configuration, as the shape of the cartridge determined just how it was oriented and when it released from the magazine. Call it timing, timing is absolutely critical for reliable feed and this is something that was carefully studied for these military bolt actions. If the gun jams, Soldiers loose faith in the things. Feed problems would be revealed very soon on the firing range, have a couple of thousand Soldiers shooting a couple of hundred rounds a day, any unreliability due to poor magazines feed would show up many times in a day.

This picture shows a P14 at the top and a M1903 at the bottom. The P14 feed lips are configured for the 303 Brit round, it is obviously shaped differently from what would be needed for a 30-06.

Here is a post 64 M70, this one has a claw extractor. Typical of the post WW2 rifles there are no integral feedlips milled into the receiver. Instead proper feeding is primarly dependant on that stamped sheet magazine box.

This is why post WW2 rifles are less reliable in feed than the typical pre WW2 rifle, these cheap, often ill fitting, magazine boxes may or may not feed your particular cartridge well. You can bend the lips of the box, you can’t do much about the ridges, if everythings lines up properly the cartridges feeds well, if there is something out of alignment between the receiver and box, feed will not be 100% positive. This is not as positive as milled integral feed lips.

There are very good reasons firearms companies eliminated integral feedlips in the receiver: it cost too much to mill those surfaces, and people don’t shoot their rifles enough to notice!

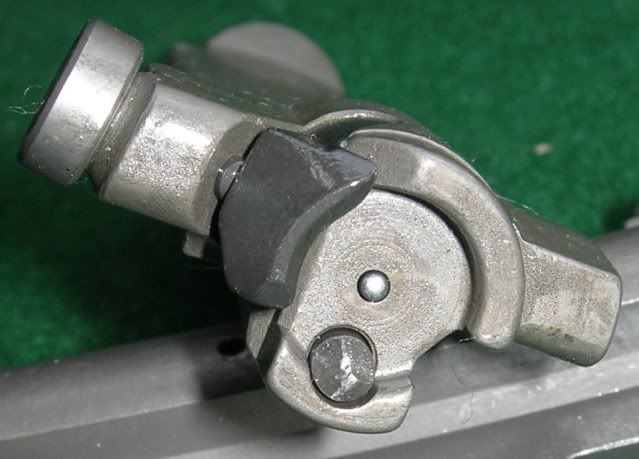

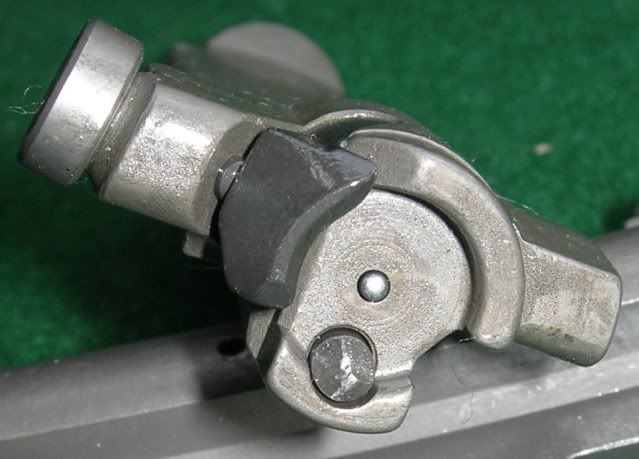

Push feed extractors are very common, when used in conjuction with properly designed rifles the feed and extraction is very reliable. This is a M14 bolt face:

The US Army spent a good deal of time making sure that the M14 feed reliably. I believe the magazine was a John Garand design, it is fairly rugged, and even though the 308 cartridge is very straight, (not the best contour for feeding) I have never had a misfeed in the 20 plus years I have been shooting a M1a. The gun is very reliable in feed and extraction.

While the AR15 is a push feed, its greatest source of unreliability is its magazine. Based on what I have read from the period, (page 65 The FAL Rifle R Blake Stevens) the Army Infantry School did not want box magazines. They wanted clips. Just like the ones in their Garands. This is typical of the Army: it likes what it has, wants something better, but only a little different. They totally reject revolutionary change. Going away from clips was a road too long for the Army. The letter on page 65 goes into all the problems of box magazines, they are heavy, they are expensive, yada, yada, yada, the Infantry School wants clips. It is my opinion that Stoner responded to the Infantry School’s desires by designing the AR15 magazines to be cheap and out of aluminum. I have read from others that the original AR15 magazines were called “disposable” to placate the infantry. I have seen period training films where the magazine in the M14 was called “semi detachable” and loading the magazine from the top with a stripper clip was being demonstrated in the film. It is a fact that the M14 has a stripper clip guide on the top of the receiver. This is there to keep the Infantry school happy, though I never met anyone who ever loaded their M14 (especially in combat) with the box magazine in place using stripper clips. I tried doing that in practice and it was not easy, it was a thumb buster in practice.

So, while the AR15 is mechanically reliable, few parts break, ever since the original issue of the rifle, the magazine has been its greatest source of unreliability. The lips on that lightweight aluminum magazine will spread in time and stovepipe jams will result.

These are pictures of a jam, during sitting rapid fire, at a Highpower match. The shooter set that magazine aside and completed the match with his “good” magazines.

AR15 jam sitting rapid fire

A good deal of the reliability of the AK47 is due to the magazines. Just take a look at the feed lips on a AK47 magazine. They are double thickness steel with machined edges. The Soviet design team understood that detachable magazines had to be rugged and they did not spare the rubles in making them reliable.