Shadow9mm. The case prep center I bought is the "Frankford Arsenal Platinum Series Case Trim and Prep System". It was around 190.00 so not really cheap, but to be quite honest it does seem to work great. We have boatloads of overtime where I work too and it just won't stop. It's a Teamsters union job where I work, so they have to offer OT from the top of the seniority list and force from the bottom up.

It's a long story, but I used to be forced to work a lot more than I am now. Being that I'm over halfway up the seniority list that doesn't happen very often unless I want the overtime. I would love to hear about your government job though man? It's interesting to hear from other government workers to find similarities and differences. I take it you must be unionized where you work, or that's a guess?

I'm guessing this Frankford Arsenal System won't work as fast as an electric drill based system, but it seems fast enough. I'm going to soon be in a similar situation as you, because I want to buy at a discount some .223 brass military surplus once fired. De-swage the primer pockets and then trim them.

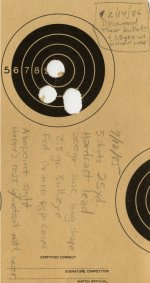

With trimming my Winchester green tip ammo in 223, case lengths were way over 1.75 inches which I trimmed down to. I can trim to exact length, chamfer, deburr and even clean the primer pocket with that Frankford Arsenal case prep center.

I would say I can do all three on one piece of brass in a rhythm in a short period of time, and I've timed it actually. If I'm focused I can average 3 pieces of brass per minute 100% prepped.

So you break that down, that's 180 per hour, so it would take probably 12 hours to prep 2 thousand pieces of brass with that. That said, that doesn't seem to horrible, and that would be down over the course of a few weekends just spending 3 or 4 hours doing it. The machine I'm referring to is this one specifically that I bought:

https://www.amazon.com/gp/product/B00HS7JEB4/

I am noticing a pattern Shadow9mm, and that is Frankford Arsenal stuff in general seems like they have decent products. Lyman also seems to have great products too, though they seem more hit an miss. Hopefully I made a decent choice with that Frankford Arsenal prep center though?

Thus far I'm impressed, and it seems like someone thought about the product before just dishing it out. The fact that the collets etc. store inside is also great.