Talk about at thread drifting off topic.

06Shooter said:

When a bolt is closed on a cartridge , is the case head pushed into the recess of the bolt face underneath the extractor claw, or does the ignition phase of it push it under the extractor claw into the bolt face ?

Normally the head is loose by the amount of excess headspace beyond the size of the cartridge case's headspacing surface. If you chamber a rimless rifle cartridge rapidly, you can actually size the case down several thousandths just by how hard it is slammed into the shoulder of the chamber. I think Hatcher reported -0.006" of shoulder setback just from operating a 1917 Enfield bolt rapidly. Self-loaders obviously have enough bolt speed to do it, too, and if you extract a self-loaded round and measure it, you'll find it is shorter, too. Indeed, the SAAMI standards seem to depend on this being possible.

Take a look at the drawing here:

http://saami.org/PubResources/CC_Drawings/Rifle/30-06%20Springfield.pdf. Remember, these are unilateral tolerances, so the number given is at the more critical end of the tolerance range, with the given tolerance only going in the less critical direction. This is a standard engineering practice. The more familiar plus or minus tolerance is used with a middle range value when neither direction is more critical than the other. In cartridges the maximum value is more critical and is the value given because a cartridge that is too big won't fit in a chamber at all, while a slightly too small one will still work. In a chamber the minimum value is critical and is the value given because a chamber that is too small won't accept a cartridge at all, while one that is slightly too big still functions, if not to best advantage. The only exceptions are for inside radii, which have to be the other way around to prevent an interference fit, and the with of the extractor groove, which cannot be too small.

Looking the drawing, the dimension from the case head of the cartridge to the 0.375" diameter shoulder datum is 2.0526-0.007". So the maximum is 2.0526" and the minimum is 2.0456". The chamber drawing below the cartridge has the dimension from the bolt face to to that same diameter on the shoulder at 2.0487-2.0587". It uses that format rather than a dimension and tolerance because this headspace determining range is a reference value. But look at those numbers closely. At 2.0526" the maximum "case headspace" is allowed to be 0.0039" longer than the minimum chamber headspace of 2.0487". The drawing allows an almost four thousandths interference fit!

How can it do that? We'll, for one, as Hatcher and self-loader owners have found, chambering can shorten the cartridge at the shoulder. It can happen because the minimum chamber diameters along the sides of the round are bigger than the maximum cartridge diameter. The chamber is a minimum of 0.0010" bigger at the head and .0015" bigger at the shoulder. This small clearance average 0.276% and is over a long enough over the 1.65" reference space, that 0.276% of that length is just over 0.004". Plus a little bit of the neck can lengthen forward. So there is plenty of room for that much interference, plus some fouling.

Typically, the maximum allowed headspace only occurs in heavily used guns who've gradually suffered enough locking lug setback for that difference to be seen. Rifle barrels have to be pretty inaccurate before the military rejects them, so that is the platform this occurs on. A match barrel has normally lost best accuracy and is replaced before the chamber grows that much.

Does that tight chamber fit mean a 0.001" hard particle could stop a shooter from closing the bolt on a minimum size chamber and a maximum size case? That might seem so in theory, but in practice, brass is so much softer than steel it will just put a tiny 0.001" dent in the brass, and do so without noticeable effect on loading or shooting.

The amount of chamber space allowed for typical new guns is no mystery. On average they are half way between the the minimum chamber length controlled by a headspace GO gauge, and a headspace NO GO gauge. For .30-06 these gauges are: 2.0487" and 2.0537", a 0.005" span. So the average .30-06 headspace is about 0.0025" over minimum and under maximum. A test gun barrel is precision chambered to within 0.0005" of minimum, and match barrels are often close to that. Other chamberings, like .308 Winchester, have a slightly tighter allowance.

So, then, what about the extractor? Look again at the SAAMI drawing. The rim, which has a surface that the extractor hook pulls on during extraction, has a tolerance of -0.010". The extractor groove in front of it is 0.033"+0.010". The wise manufacturer will plan to have the edge of the extractor claw fall in the middle that recess, so it will land about 0.0165 in front of a maximum thickness rim, and 0.0215" in front of an average thickness rim when the case head is firmly against the bolt face. Even with a maximum thickness rim, for it to reach the extractor claw during firing requires the case to move further forward than the headspace determining shoulder will allow, even when the case is chambered fast and shortened a few thousandths, as Hatcher measured it.

In normal firing, the firing pin just drives the case forward through the primer contact until its shoulder meet the chamber shoulder. As pressure starts to build, the case expands to meet the sides of the chamber. In a high power rifle, the pressure gets high enough before the bullet starts to move that the brass is stuck to the chamber wall by friction before the pressure can make it back up. This leaves the length of any excess headspace between the case head and the breech face. But the pressure is so high that the brass can't withstand it without support from the steel chamber, so when the head is forced back, what gives is the brass stretching where the inside of the head meets the case wall, forming and thinning the pressure ring.

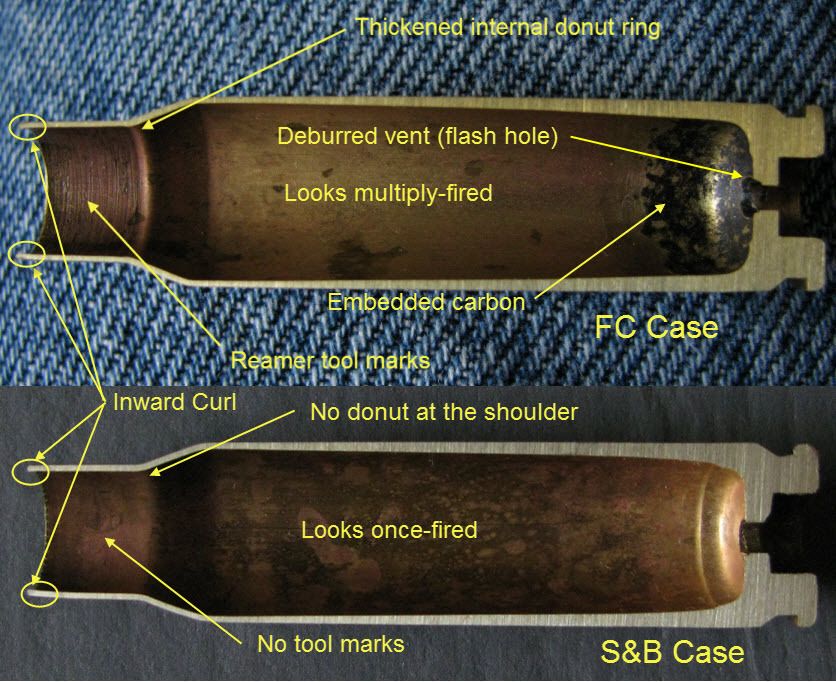

That is what makes the rifle cases grow. When you resize the case later, that stretched portion, despite thinning a little, is still thicker than the brass near the shoulder, so it holds up to resizing forces while the shoulder gets pushed down, with the excess brass flowing into the neck. It's never 100% successful at making the turn from the shoulder angle to up the neck, so it overshoots a little, which is what forms the internal donut. But the extra brass has ultimately come from down at the pressure ring, so it doesn't need to be preserved, as there's no way to put it back down there. So there's nothing wrong with cutting the donut away with an inside reamer if your bullets seat down far enough for it to interfere with them. The .30-06 has such a long neck that this is only likely to happen with very long bullets. If you are shooting typical match bullets in the 180 grain range and below from this cartridge, you may never have to worry about it.

The upper sectioned .308 case below shows the "dreaded donut". It also shows reamer marks from someone cutting away a previous donut, so this case was well used;