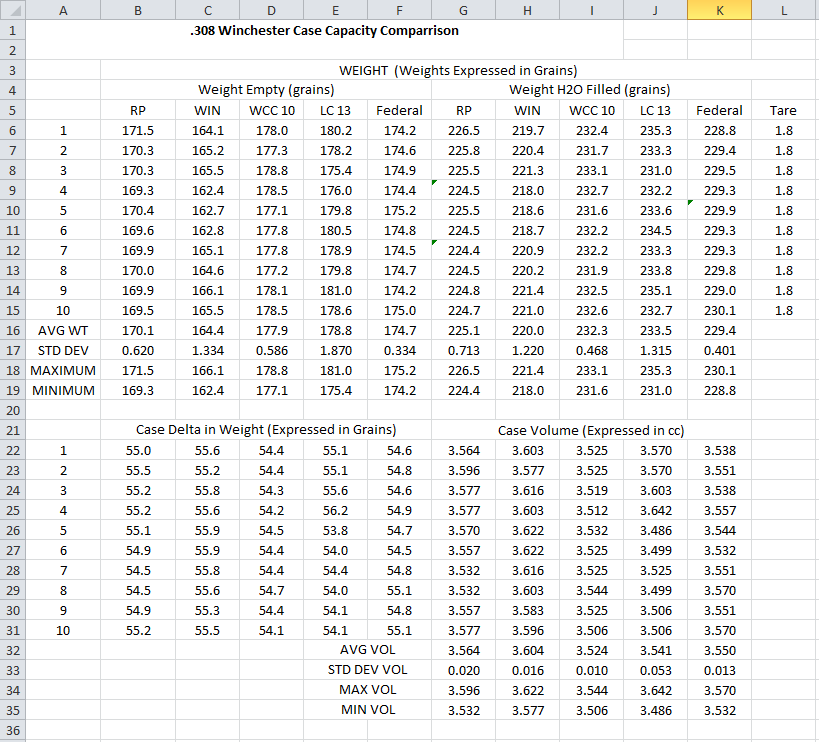

I would think that would leave someone wide open to law suits? I know a good number of people that load that don't give a though to mixing case's. If they are doing 300 mag or 308 and they can vary as much as 8grs difference in capacity, how come we don't hear about more blown up guns?

The main reason we don't hear about lots of lawsuits is that there are still some things in law that make what you do, your own responsibility.

The reason we don't hear about more blown up guns is that most of the time, even extreme pressure variations due to case volume variations don't reach blow up levels. Most of the time.

The fact that brass from different sources varies is a long known thing. Known for as long as there has been brass from different sources. Knowing that loads must be tailored for the components used is a fundamental part of reloading, always has been.