You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can "plonked" rounds become "Unplonked"?

- Thread starter robhic

- Start date

Since you were using a 45 GAP charge and a 45 GAP OAL, it is logical to conclude you accidentally looked up 45 GAP rather than 45 ACP.

My father got me to create and use a set of written reloading procedures and an associated checksheet that travels with the cartridges throughout the process and then gets filed for future reference. The checksheet has saved me from making mistakes regarding load, powder, and the like more than once over the last 40 years of reloading. I strongly encourage you to adopt a similar practice.

I think that is a pretty good idea to post a checklist. I always pick the load I am going to use, write it down in my log and keep that alongside me when loading.

As far as the GAP load, no problem, I just misread my '2' as a '0'. I originally loaded the rounds to 1.270", hence the problem firing and subsequent lockup.

Thanks for the idea.

lee n. field

New member

This is curious (to me). I made some .45acp rounds 2 days ago. A 200gr round-nose plated Ranier bullet over 7.0 gr of HS-6 powder.

My normal method is to assemble the round and use the barrel of my Glock G36 45acp pistol as a gauge, starting with the OAL suggested in the manual. I then adjust seating depth until the round(s) plonk and I am good.

I made up 50 rds this way and went to the range with my granddude today to do some shooting. Two-three rounds fired and 4th locked up the gun.

I got it apart and tried another round in the mag. Locked. Depth was just a bit too long. I stopped and we finished the 9mm portion of our programD) then left. Tried again at home and sure enough, a bit long. I tried to seat the round a bit deeper and it got better but not 100%. At this point, the bullet, IMO, looks like it's getting deeper than I'd like. Any ideas how to re-plonk these 50 trouble-makers without seating getting too deep? Thanks for ideas.

As long as it's not biting the rifling, run it through a Lee Factory Crimp Die.

Marco Califo

New member

robhic,

"I generally plonk "

Actually you are generally plunking. You keep misspelling it. Several posters have corrected you.

At first I thought you referring to "Glocking" or bulging case firing in a Glock with a partially unsupported chamber.

You unGlock a bulged case by resizing, and dies are made for this exact purpose. My G23 does not bulge cases. That seemed to be more of an issue with earlier Glocks.

As to "un-plunking" I still do not know exactly what you mean by that.

Your rounds passed the plunk test, but now, you think they do not?

If you have factory rounds on hand, and fire those without a problem, then something is amiss with your reloading process.

There is actually a word "plonk" but that word is being incorrectly used here, and given the definition below, makes no sense in this context.

Dictionary

plonking

plonk

pläNGk/Submit

informal

verb

gerund or present participle: plonking

1.

set down heavily or carelessly.

"she plonked her glass on the table"

2.

play on a musical instrument laboriously or unskillfully.

"people plonking around on expensive instruments"

"I generally plonk "

Actually you are generally plunking. You keep misspelling it. Several posters have corrected you.

At first I thought you referring to "Glocking" or bulging case firing in a Glock with a partially unsupported chamber.

You unGlock a bulged case by resizing, and dies are made for this exact purpose. My G23 does not bulge cases. That seemed to be more of an issue with earlier Glocks.

As to "un-plunking" I still do not know exactly what you mean by that.

Your rounds passed the plunk test, but now, you think they do not?

If you have factory rounds on hand, and fire those without a problem, then something is amiss with your reloading process.

There is actually a word "plonk" but that word is being incorrectly used here, and given the definition below, makes no sense in this context.

Dictionary

plonking

plonk

pläNGk/Submit

informal

verb

gerund or present participle: plonking

1.

set down heavily or carelessly.

"she plonked her glass on the table"

2.

play on a musical instrument laboriously or unskillfully.

"people plonking around on expensive instruments"

Marco Califo

New member

Oh, I think I get it now:

>> You passed the plunk test with the firearm disassembled.

>> Did you then try to cycle and chamber (with the gun reassembled)?

You could pass the plunk test, but not be able to chamber (and cycle) the exact same cartridge. This would happen if you drop the round in the barrel and it looks normal, but if it is too long, you may not notice it sticking up higher than it should. Perhaps by a tiny amount. Then reassemble the gun, and the long length then could cause issues.

>> You passed the plunk test with the firearm disassembled.

>> Did you then try to cycle and chamber (with the gun reassembled)?

You could pass the plunk test, but not be able to chamber (and cycle) the exact same cartridge. This would happen if you drop the round in the barrel and it looks normal, but if it is too long, you may not notice it sticking up higher than it should. Perhaps by a tiny amount. Then reassemble the gun, and the long length then could cause issues.

"I generally plonk "

Actually you are generally plunking. You keep misspelling it. Several posters have corrected you.

I've seen it spelled both ways - 'plOnk and plUnk. Tomato - tomatoe. And in this (reloading) context, was there any question as to my reference?

Oh, I think I get it now:

>> You passed the plunk test with the firearm disassembled.

>> Did you then try to cycle and chamber (with the gun reassembled)?

You could pass the plunk test, but not be able to chamber (and cycle) the exact same cartridge. This would happen if you drop the round in the barrel and it looks normal, but if it is too long, you may not notice it sticking up higher than it should. Perhaps by a tiny amount. Then reassemble the gun, and the long length then could cause issues.

After using the disassembled barrel for the plunk test, I did NOT hand-cycle the gun. 1) because I was using info from previous loadings using that OAL and 2) any cycling of live ammo is not something I like doing if I don't have to. The rounds loaded previously shot fine. I was just clearing out the last 50 rds of the Ranier 200gr plated RN bullets I had on hand.

Why some (3) fired and the rest jammed is a mystery. I randomly checked OAL on the rounds after setting the initial length. They were OK. Two days later - they weren't. I think I am gonna set my OAL about 0.010" less in the future and see how that affects them.

Glad you got the length sorted.

Brass has tolerances, too. I've weighed and measured enough of it to know that most makers mix brass coming off multiple forming die sets. It's not uncommon to be able to identify four or more distinct sets of brass, plus there is some bell curve distribution within the output of each set of tooling. So you got three off tooling that made them thin enough at the base so they were still not too fat to just fit in the chamber, even with the bullet base widening them, then got one that was thicker.

Look back at my post #15. Already done!

robhic said:My only curiousity is how the 3 rounds loaded to 1.270" fired yesterday. Three fired and #4 locked up the gun. I plonked all of the re-seated rounds just to be sure.

Brass has tolerances, too. I've weighed and measured enough of it to know that most makers mix brass coming off multiple forming die sets. It's not uncommon to be able to identify four or more distinct sets of brass, plus there is some bell curve distribution within the output of each set of tooling. So you got three off tooling that made them thin enough at the base so they were still not too fat to just fit in the chamber, even with the bullet base widening them, then got one that was thicker.

hdwhit said:Perhaps if someone has access to Quickload, they could run 7 grains of HS-6, a 200 grain plated bullet

Look back at my post #15. Already done!

PLUNK ,PLUNK, PLUNK

I did not see this mentioned anywhere. After you seated the bullets did you remove the FLAIR ie) taper crimp the round to remove the flair.??

Then PLUNK them in the empty barrel. It should drop in (PLUNK) THEN turn the barrel over and the round should FALL out. If not then seat a tad deeper until it does,

This is not advanced rocket science. Yes, a clean chamber and barrel will make a difference.

Yes, a clean chamber and barrel will make a difference.

The choice of HS6 for the 45 ACP is well. another topic.

I did not see this mentioned anywhere. After you seated the bullets did you remove the FLAIR ie) taper crimp the round to remove the flair.??

Then PLUNK them in the empty barrel. It should drop in (PLUNK) THEN turn the barrel over and the round should FALL out. If not then seat a tad deeper until it does,

This is not advanced rocket science.

The choice of HS6 for the 45 ACP is well. another topic.

Attachments

Just a random thought; if you are using a plated round nose bullet, why are you using LSWC data? If you don't have plated bullet data why not use lead round nose data? Lyman manual had data for a LRN bullet of 225 gr. and OAL info from that should work for your plated bullets...

Jim Watson

New member

For historical usage, see:

https://www.youtube.com/watch?v=G6a3fck0NBI

The modern usage for "plonk" is to not accept posts from a disagreeable internet correspondent.

https://www.youtube.com/watch?v=G6a3fck0NBI

The modern usage for "plonk" is to not accept posts from a disagreeable internet correspondent.

Just a random thought; if you are using a plated round nose bullet, why are you using LSWC data? If you don't have plated bullet data why not use lead round nose data? Lyman manual had data for a LRN bullet of 225 gr. and OAL info from that should work for your plated bullets...

I was using a ".45acp Load Book" and found the data for a lead WC bullet of 200gr weight. Figuring LWC and plated RN would be similar, except for bullet OAL, I used the lead bullet and seated at an OAL I had used previously with my plated RN bullets. I then used the barrel for OAL for the RN bullet and trial and error until these rounds worked upon dropping in, turning and dropping out of my barrel was good, IMO. I guess Uncle Nick's explanation is the reason the rounds worked before and 3 worked this time before locking up the gun.

I did not see this mentioned anywhere. After you seated the bullets did you remove the FLAIR ie) taper crimp the round to remove the flair.??

Then PLUNK them in the empty barrel. It should drop in (PLUNK) THEN turn the barrel over and the round should FALL out. If not then seat a tad deeper until it does,

I removed the flair, TURNED THE ROUNDS and let them drop out without help. Some fired some didn't. The barrel was clean and coated with EEZOX dry lubricant.

I removed the flair, TURNED THE ROUNDS and let them drop out without help. Some fired some didn't. The barrel was clean and coated with EEZOX dry lubricant.

Turned the rounds?? Or turned the barrel upside down??

Didn't fire? or got jammed??

Did not fire is a different situation.

Your COL should be around 1.259 give or take a hair. A few thousandths is not gonna matter but can make the difference between go and no go,

Accurate powder has data for your 200 gr RN and that is their listed length (with different powder)

Turned the rounds?? Or turned the barrel upside down??

Didn't fire? or got jammed??

Did not fire is a different situation.

Your COL should be around 1.259 give or take a hair. A few thousandths is not gonna matter but can make the difference between go and no go,

Accurate powder has data for your 200 gr RN and that is their listed length (with different powder)

Last edited:

Rule3,

If you read the rest of the thread, you will learn the manufacturer recommends 1.240" COL for this particular bullet shape. The huge variety of shapes now available has eliminated a lot of interchangeability by weight that used to exist. This article explains it.

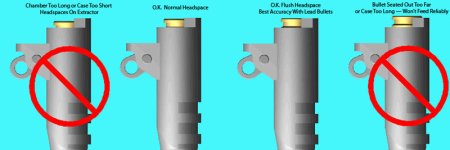

Here's a newer version of that old image of mine with a little more explanatory labeling added:

If you read the rest of the thread, you will learn the manufacturer recommends 1.240" COL for this particular bullet shape. The huge variety of shapes now available has eliminated a lot of interchangeability by weight that used to exist. This article explains it.

Here's a newer version of that old image of mine with a little more explanatory labeling added:

Robert

Can you post clear pictures of your bullets and cases unassembled and assembled?

I'm seeing LSWC (lead semi-wadcutter and LWC (lead wadcutter) compared to the plated RN and COL for a 9mm among other things. Wadcutters are generally seated flush with the case mouth which gives minimal volume under the bullet. You won't find any data for wadcutters useful for loading plated round nose bullets

You got a bunch of guys willing to look over your shoulder to help you get through this....pictures would be of great help.

Also, the plunk test won't pick up issues with the bullet seated too deep.

Can you post clear pictures of your bullets and cases unassembled and assembled?

I'm seeing LSWC (lead semi-wadcutter and LWC (lead wadcutter) compared to the plated RN and COL for a 9mm among other things. Wadcutters are generally seated flush with the case mouth which gives minimal volume under the bullet. You won't find any data for wadcutters useful for loading plated round nose bullets

You got a bunch of guys willing to look over your shoulder to help you get through this....pictures would be of great help.

Also, the plunk test won't pick up issues with the bullet seated too deep.

jag2 wrote:

What am I missing?

What you're missing is that the OP is loading 45 ACP which should NOT be 1.070.

The fact the OP started with a 7 grain load and OAL of 1.070 rather than 8.2 grains and an OAL of around 1.225 which Hodgdon (maker of the powder) and other published manuals say to use strongly suggests the OP was loading 45 ACP using 45 GAP data.

"If you read the rest of the thread, you will learn the manufacturer recommends 1.240" COL for this particular bullet shape. The huge variety of shapes now available has eliminated a lot of interchangeability by weight that used to exist. This article explains it."

Yes Rainer stated 1.240

What barrel did they test it in?

Accurate Tested it at 1.269

So it goes to show again that it is up to the individual chamber/barrel to determine what works.

The length I provided was an example from ACCURATE with that bullet and whatever barrel. It is a starting point. The exact seating depth or COL is up to the individual and HIS barrel

As with any bullet the OP can start long and adjust it until it actually PLUNK tests properly, it should not be this complicated.

Just a WAG but the OP is seating the bullets too long.

As a example form another bullet, Hodgdon seats ALL the 230 gr bullets RN or FN) at 1.200. I don't seat them that short.

Yes Rainer stated 1.240

What barrel did they test it in?

Accurate Tested it at 1.269

So it goes to show again that it is up to the individual chamber/barrel to determine what works.

The length I provided was an example from ACCURATE with that bullet and whatever barrel. It is a starting point. The exact seating depth or COL is up to the individual and HIS barrel

As with any bullet the OP can start long and adjust it until it actually PLUNK tests properly, it should not be this complicated.

Just a WAG but the OP is seating the bullets too long.

As a example form another bullet, Hodgdon seats ALL the 230 gr bullets RN or FN) at 1.200. I don't seat them that short.

Guess I'll throw this out there too. I have a 9mm that I can load 115gr or 124gr RN bullets all the way out to 1.180 and the will still plunk just fine in the barrel. Only they will not fit into the magazine. So by this parameter I could load as long a case as will fit in the mag and then adjust the powder charge. Problem then is that these loads will not fit into my other 9mm which has a very tight chamber.