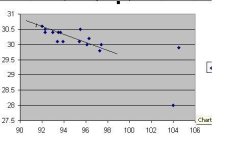

Lost Sheep said:Steve 4102, I looked at the table you mention in post #13 that is linked in post #2. I believe it shows clearly that as case weight goes up, case capacity goes down.

It also shows clearly that the two are not locked together in a way that is terribly useful to the discerning handloader, so I do take your point. Measuring the primary object of your attention (capacity) is always superior to measuring a proxy (case weight).

I wonder if the O.P. weighed the brass with primers in place (probably, else the water would leak out) and if primer weight makes much of a difference? I also wonder if the cases were sized and trimmed before the water capacity was determined? How much care was taken to ensure temperature was controlled and air bubbles prevented? Was powder reside inside the cases a factor?

These are just the wrinkles in the measuring process I could think of immediately.

Just covering all the bases, I am,

I guess we are not looking at the same chart.

Here is the link again.

http://www.6mmbr.com/223rem.HTML

Right off the bat with #2 and #3,

WCC99 weight=95.5, Capacity=30.5

S & B Weight=92.3, Capacity=30.5

Same capacity different weight.

Another example,

Federal weight= 96.3, Capacity=30.2

Hornady weight=93.9, capacity=30.1

In the above, the federal case weighed +2.4gr+ more than the Hornady case, yet the Federal case had .1gr More capacity.