The one thing I NEVER see posted about annealing is a spotlessly clean case, especially inside the neck.

Any crud, carbon, trace metals can and will find their way into the brass,

Same way carbon finds its way into steel when heated.

You are heating, expanding the distance between molecules, and you are expanding large enough for trace metals, carbon & crud to enter.

The ONLY way to keep that crap out is for the crap NOT to be there in the first place.

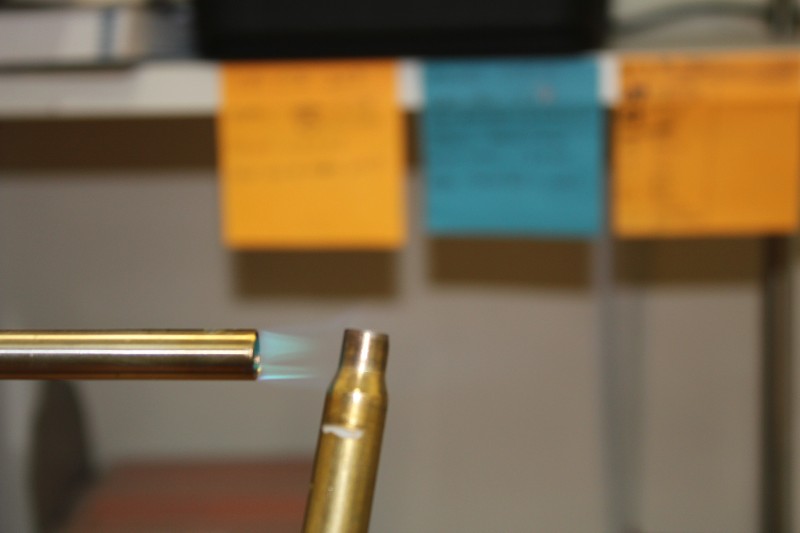

If you are going to anneal anywhere near properly, find a way to clean the INSIDE of the case, as well as the outside of the case.

Now, welders can confirm this,

You CAN NOT use a common carbon steel brush, or abrasives containing carbon on stainless steel, or it WILL rust/corrode.

The same is true with brass/gas welding.

Oxygen/air containing carbon can't be allowed to enter many kinds of heating treating/welding operations, or the metals will be contaminated on a molecular level.

Cartridge brass isn't quite that sensitive, but you will want to take precautions like clean brass for annealing to a 'Normalization' temperature.

While doing a lot of research on annealing processes, I found significant antimony & carbon contamination in the used brass vs new brass...

If the brass was THROUGHLY cleaned, the contamination penetration into the brass was almost nothing.

This told me clean cases don't absorb contaminants during the firing process, the case didn't stay hot enough, long enough to absorb firing contaminants,

But annealing a dirty case reached temperatures high enough for long enough to contaminate the brass.

Guys reloading range ammo won't care, they will dry media tumble, leave the inside of the case neck dirty, and never have consistent neck tension anyway since most crimp and/or don't check for consistent neck diameter anyway.

I see guys pre porting to be loading 'Accuracy' loads, when they post pictures the inside of the case neck is FILTHY.

Absolutely NO WAY to get consistent neck tension or bullet release with a filthy neck... So there 'Accuracy' has to be coming from somewhere else...

Also, filthy necks have ZERO chance of resizing correctly, and dragging a sizing ball through that crud just has got to be scratching the crap out of the brass & sizer ball...

I used brushes for years, scrubbing cases by hand before sizing/annealing,

Since I switched to stainless pin media, no more hand scrubbing! YEAH!

I found my sizing die & neck ball to be much cleaner when done also, another big plus since I didn't have to disassemble the sizing die and scrub all the parts by hand, now I can clean it with spray can solvent and be done with it.