You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aluminum Guns

- Thread starter yrralguthrie

- Start date

yrralguthrie

New member

Aluminum

I don't use junk aluminum. I do use a very small precision lathe and I'll stand by my statements. Aluminum requires more care, different coolant, different mills and cutters. Mills need to be 2 flute instead of 4 flute. 6061 WILL gum up on a 4 flute. That is just general machining knowledge. Stainless steel IS harder to mill than mild steel. The cutters must be very sharp and high speed steel is preferable over carbide because they can be sharper.

Your experience not withstanding, I can go on any machinist form and the general opinion will be the same as mind. Machining faster on a CNC, I have a machinist friend, who is good enough he is making money(lots of money). Shipping $100,000 to $200,000 a month. He also tells me mild steed will cut easier than aluminum. Tool steel is not the same thing. It is made so as not to cut. Some will have to be annealed. I challenge you to cut the inside of a bicycle hub. But then that's why I said mild steel. It is certainly harder to get a fine finish on Aluminum than steel. A rank amateur can mill mild steel, it takes some experience and knowledge to machine aluminum. Part of machining is welding, and a welder for aluminum cost several times more than a MIG torch for steel, and lot more experience and is slower. Aluminum is harder to finish to the same smoothness as steel.

I am assuming you put the smiling face on the following because you were joking. You surely were serious.

I can tell you from first hand machining experience, that's only true for low grade aluminum like they use for toys. 6061 or better machines very smooth and easier than mild steel, and will not gum up the cutting bit. In fact, you can even tap 7075 without a steel insert with good results. Try that with low grade aluminum and you do indeed have a gummy mess.

Machinist catalogs, Manhatten, Enco, McMaster sell drills and mills special made to use in aluminum so as to not catch and gum up the flutes.

Ah...hadies...I hijacked my own thread. But then I never believed that "ignorance is bliss."

ljg

ljg

I don't use junk aluminum. I do use a very small precision lathe and I'll stand by my statements. Aluminum requires more care, different coolant, different mills and cutters. Mills need to be 2 flute instead of 4 flute. 6061 WILL gum up on a 4 flute. That is just general machining knowledge. Stainless steel IS harder to mill than mild steel. The cutters must be very sharp and high speed steel is preferable over carbide because they can be sharper.

Your experience not withstanding, I can go on any machinist form and the general opinion will be the same as mind. Machining faster on a CNC, I have a machinist friend, who is good enough he is making money(lots of money). Shipping $100,000 to $200,000 a month. He also tells me mild steed will cut easier than aluminum. Tool steel is not the same thing. It is made so as not to cut. Some will have to be annealed. I challenge you to cut the inside of a bicycle hub. But then that's why I said mild steel. It is certainly harder to get a fine finish on Aluminum than steel. A rank amateur can mill mild steel, it takes some experience and knowledge to machine aluminum. Part of machining is welding, and a welder for aluminum cost several times more than a MIG torch for steel, and lot more experience and is slower. Aluminum is harder to finish to the same smoothness as steel.

I am assuming you put the smiling face on the following because you were joking. You surely were serious.

I can tell you from first hand machining experience, that's only true for low grade aluminum like they use for toys. 6061 or better machines very smooth and easier than mild steel, and will not gum up the cutting bit. In fact, you can even tap 7075 without a steel insert with good results. Try that with low grade aluminum and you do indeed have a gummy mess.

Machinist catalogs, Manhatten, Enco, McMaster sell drills and mills special made to use in aluminum so as to not catch and gum up the flutes.

Ah...hadies...I hijacked my own thread. But then I never believed that "ignorance is bliss."

ljg

ljg

Last edited:

While I have seen exactly one picture of a 1911 with a crack from the slide pin stop to the frame rail (directly above) I would not agree that it is "trouble waiting to happen". I can list numerous motorcycle/automotive applications using tapped holes in aluminum.

A slide stop pin hole is not a tapped hole.

Threads in aluminum need to be coarser to have good strength compared to typical gun steel.

Threaded holes n aluminum are barely harder to tap then steel, but are not suitable for repeated use with steel screws.

They are fine for a single use, or even infrequent maintenance use.

They are a real weak point if repeated dis-assembly and assembly are needed.

They simply do not stand up to steel screws very well.

Steel thread inserts nicely solve the problem by providing a hard surface for the screws to bear against, and a slight larger hole in the aluminum for some additional strength.

The automotive industry is NOT known for dealing with maintenance issues well.

It is not their problem after the warranty runs out.

Threaded holes n aluminum are barely harder to tap then steel, but are not suitable for repeated use with steel screws.

I've never seen aluminum that was harder to tap than steel. I wish I had a dollar for every aluminum tapped hole that will last the lifetime of the car / motorcycle it's in.

I will go so far as to say if you have something that is going to be disassembled repeatedly, as in nearly every day, then you might want to consider a steel liner. Otherwise, no.

Mills need to be 2 flute instead of 4 flute. 6061 WILL gum up on a 4 flute.

Wrong. Never happened to me in over 40 years of machining. Too many things wrong to answer. But this is not supposed to be a debate between us. Although I usually use a two flute mill for chip relief.

Aluminum frames can be good or bad just like steel frames. Just depends on design and quality manufacturing.

yrralguthrie

New member

On topic

Back to my original question. After winnowing the chaff, (that's chaff not chad ), it seems pretty clear that an aluminum alloy gun is superior for carry. It's lighter and will outlast the carry person.

), it seems pretty clear that an aluminum alloy gun is superior for carry. It's lighter and will outlast the carry person.

For a range gun, I lean to a stainless steel gun. Regardless of what is generally thought and said, I think the stainless used in guns is harder and tougher than the mild steel used in guns. While steel can be hardened to be harder than stainless, mild steel is not harder than stainless. Think before you reply.

For many years steel was the preferred material for knives...hardened steel. Today most knives are made from stainless steel or Damascus steel. Both will take and hold an edge far longer than hardened knife steel. Better wear. So I expect that the stainless on guns will be superior to the mild steel that is used. Even with a high quality surface treatment, I don't see any reason SS won't outlast a regular steel gun. If you want to disagree with me on this I require a real test. Two guns fired side by side until one fails. Done multiple times.

Of course Damascus was also used hundreds of years ago.

ljg

Back to my original question. After winnowing the chaff, (that's chaff not chad

For a range gun, I lean to a stainless steel gun. Regardless of what is generally thought and said, I think the stainless used in guns is harder and tougher than the mild steel used in guns. While steel can be hardened to be harder than stainless, mild steel is not harder than stainless. Think before you reply.

For many years steel was the preferred material for knives...hardened steel. Today most knives are made from stainless steel or Damascus steel. Both will take and hold an edge far longer than hardened knife steel. Better wear. So I expect that the stainless on guns will be superior to the mild steel that is used. Even with a high quality surface treatment, I don't see any reason SS won't outlast a regular steel gun. If you want to disagree with me on this I require a real test. Two guns fired side by side until one fails. Done multiple times.

Of course Damascus was also used hundreds of years ago.

ljg

Last edited:

Both will take and hold an edge far longer than hardened knife steel.

Please stop. Even 440 stainless is not as hard as D2 tool steel that can be brought up to an RC 0f 65 plus with no problem. Harder does mean longer edge, except for chipping. But stainless is a good overall steel to use for commercial knives.

Sorry, but it's hard to disregard.

stainless steel or Damascus steel.

For what it worth, two completely different steels. I am done.

Bill DeShivs

New member

yrralguthrie-

Your comments on steel, especially knife steel- are very wrong. You obviously just like to post.

Your comments on steel, especially knife steel- are very wrong. You obviously just like to post.

I can list numerous motorcycle/automotive applications using tapped holes in aluminum.

My experience with aluminum on motorcycles blocks and cases is that tapped holes strip out very easily, that cases crack with just a little stress, that whatever finish is applied to the aluminum easily flakes off and is prone to corroding. How many steel screws have I had to drill and tap out because of corrosion, or replace brake resoviors due to severe corrosion. The bottom line is that on motorcycles aluminum being light, is probably necessary, but it's still cheap crap that is far from durable.

In fact, it's probably the aluminum that I've encountered working on my own motorcycles over the past 20 years or so that make me HATE this material so much. Perhaps I'm a racist - I hate anything the color of aluminum!

No doubt that a heli-coil insert is the best way to use a steel screw in aluminum.

I bow to the knife expert.

Bill DeShivs said:yrralguthrie, Your comments on steel, especially knife steel- are very wrong

I bow to the knife expert.

"I've never seen aluminum that was harder to tap than steel. I wish I had a dollar for every aluminum tapped hole that will last the lifetime of the car / motorcycle it's in."

Some of the very high strength grades have a significant carbide content and eat up taps like crazy, and leave a less than acceptable thread finish.

Aluminum is no match for steel screws.

The I have never seen a steel screw snap before ripping out the aluminum threads, even with the correct coarse threads.

Some of the very high strength grades have a significant carbide content and eat up taps like crazy, and leave a less than acceptable thread finish.

Aluminum is no match for steel screws.

The I have never seen a steel screw snap before ripping out the aluminum threads, even with the correct coarse threads.

mete said:No one has brought up the term 'scandium ' !! Scandium guns are nothing more than aluminum alloys with less than 1% scandium.

Good point. It does add strength to aluminum.

I put them together with the other alloy frames. I would like to have a Smith 1911 scandium....just as soon as I can justify to the wife.

No one has brought up the term 'scandium ' !! Scandium guns are nothing more than aluminum alloys with less than 1% scandium.

In many cases it takes surprisingly small amounts of an alloying element to alter the base metals properties.

yrralguthrie

New member

Scandium

I guess what goes around, comes around.

Scandium is one of the alloying agents in 5052 and in 7075 aluminum.

ljg

I guess what goes around, comes around.

Scandium is one of the alloying agents in 5052 and in 7075 aluminum.

ljg

Last edited:

Damascus steel is the most nebulous term I can think of though 1911 guns have been made of 'damascus' steel.

"Damascus steel" is a better defined term than "tactical"!

True Damascus steel is made in Damascus. The layered steel (or iron) with its typical ripple pattern finish has been highly thought of for centuries for knives, swords and some other applications. Modern firearms is not one of them. "Damascus" steel has been widely counterfited over the years.

In the US, anything made with the ripple finish of Damascus steel was called damascus, back in the 19th century. Just as enameled metal was called "Japaned" at one time.

Many high grade shotguns had "Damascus" barrels, made by using 6 or 8 steel straps wound around a mandrel, and hammer welded together. Less expensive guns might use 4, or only 2 straps and were properly called "stub twist barrels" although in common parlance "Damascus" was often used for them as well.

With the advent of smokeless powder, Damascus barrels proved unsuitable for the pressures involved, often "unraveling" at an unpredictable interval. My Grandfather had a "stub twist" Ithaca 12ga, which he sold to a neighbor when he got his "fluid steel barrel" Ithaca in 1909. The stub twist gun worked fine, until the barrel came apart about 1940.

In over 40 years of shooting and studying gun lore as a hobby, I have never

seen, or heard of a "Damascus" 1911 pistol. Are you prehaps, referring to a damascus barrel shotgun, made in 1911? The manufacturing method used to make "Damascus" steel is totally unsuited to a handgun, and if you have one, or one that looks like Damascus, you either have one of the most oddball guns on the planet, or something made up to try and cheat the buyer.

Aluminum does fatigue, especially under bending stresses. However the B-52 has been flying for something like 50 years and is expected to fly until at least 2030. If someone shoots a aluminum frame gun for 80 years with anything like the stress put on a typical B-52, it may fail.

Aluminum has a finite fatigue life. Bend a piece of aluminum enough times and it will break. No matter how thick. The thicker the piece the less it will bend for the same load, but given enough bend cycles, aluminum will break. Thin steel sections have a finite fatigue life, but if you make the steel thick enough, and don’t bend it beyond a certain point, steel can withstand an infinite number of cycles.

http://en.wikipedia.org/wiki/Fatigue_(material)

The de Havilland Comet is a particularly good example of the misfortune of aluminum metal fatique. Planes, with full passenger loads, fragged and fell into the sea. http://en.wikipedia.org/wiki/De_Havilland_Comet

All aircraft have flight cycle limits. At some point the entire structure has to be replaced or the plane will crash. As the USAF began scrapping its C-141 fleet, they reduced the payloads those planes would carry, as those airframes were reaching their fatigue lifetimes.

As for aluminum handguns, in time the frames will crack. I have been told that all aluminum framed Beretta M92’s will crack around 35,000 rounds.

You have a trade off, if you want lightweight, then you have to accept a reduced lifetime with an aluminum framed handgun.

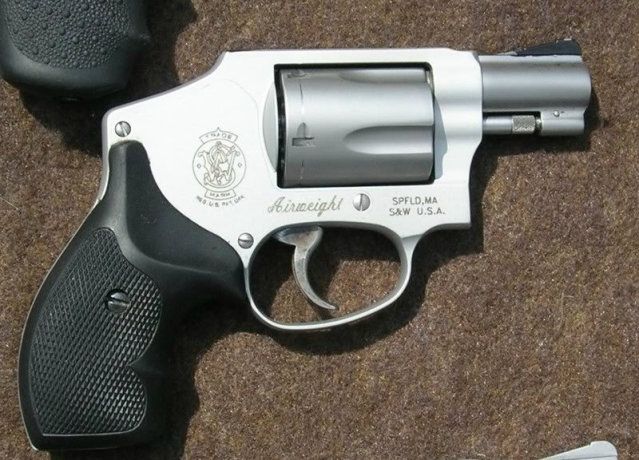

That is fine with me as I will never shoot my Airweights enough to crack a frame.

Incidentally, about a ship a week breaks in half due to metal fatigue. Metal fatigue, instead of alien abduction, is a better explanation for many "Bermuda Triangle" stories.

Last edited:

Edward429451

Moderator

I used to not like aluminum guns because they might be weak or wear faster etc..but then plastic guns came out so now I like aluminum more