I have shot tighter groups before but no consistency with my replica loads. One thing I know could be a factor is all my different casings. (Headstamps)

Oh yes if you want real accuracy you will need to separate your brass by head stamp . No if ands or buts about it . There can be significant case volume differences from one brand to the next . Winchester for example will likely have more case volume then LC . That alone will change your pressure and barrel time and where the bullet leaves the barrel in relation to barrel whip . Once they're separated and you find that great load . Continue to use that brass for that load . You may find another head stamp shoots that load good as well . If so cool for you . How ever I promise you they all will not shoot that load the same .

Next time out separate your already loaded rounds by head stamp and shoot those in groups of 5 . You'll be amazed what you see . I bet you not only see some brass group better then others . You will see POI ( point of impact ) shifts from group to group . Maybe not all but at least one will group in a different place on the target . It wont likely be a huge shift but assuming you can shoot well . It should be noticeable .

METAL GOD that was a hell of a lot of info. Not sure I should start with max oal but will definitely start pushing it towards the lands and see. I know last year I loaded some 168 grn a max with 43 grns 4064 and at .005 off the lands I was blowing an occasional primer out of the case. I think I will play it safe and

That was my very point . As I explained in one of my post

The issue turned out that at 2.845 I get sticky bolts every once and a while that I do not get at 2.815 .

Meaning my 43gr charge at 2.815 was fine with no pressure signs but when I seated the bullet .030 closer to the lands I got sticky bolt lifts ( a clear over pressure sign ) So just seating the bullet closer to the lands with an existing load that had no pressure signs . Suddenly created pressure issues . That IMHO was do to the fact 43gr at 2.815 was already pushing close to max pressures . When I seated the bullets closer to the lands .It created more pressure resulting in sticky/heavy bolt lifts .

In short , yes you are correct in saying I'll play it safe and work my load up .

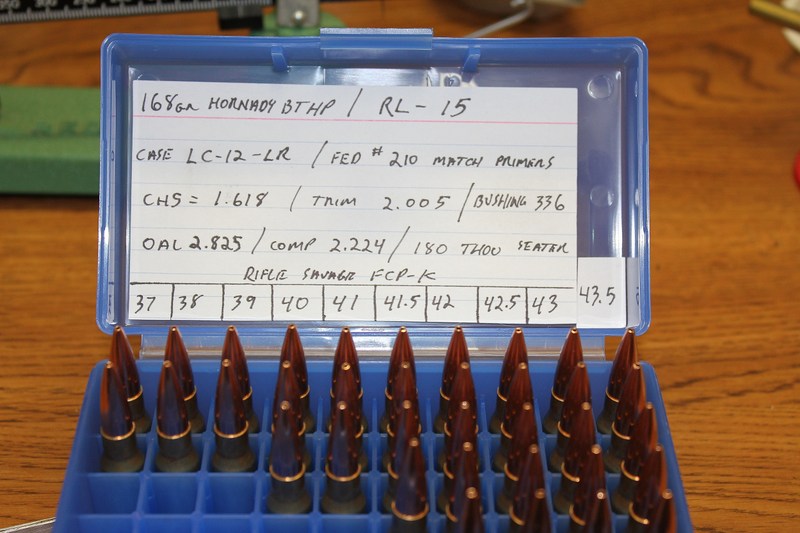

Here's a load work up a did a little while back

One might ask why do those minimum charges only have 2rds and the complete work up progresses with more and more rounds as the charge weight goes up .

I do that when I have a specific goal in mind . In this case I wanted this load to be a long range 800yd load . So I knew the lower charge weights were not likely to give me the velocities I would be looking for . How ever you should still start at or very close to minimum charge just to be sure you're not over pressure right from the get go . So those lesser charges are there only to be sure I'm safe pressure wise and can continue to the higher charges where I knew my likely final charge would be . At the time I had never used RL-15 or that bullet so I had no idea how my rifle would react to that combo so I made sure I erred on the side of caution and started low .

Last edited: