I agree with everything you have said down to :

ireload, while I understand your point,actually,usually it is not the shoulder that moves.

First,the brass is thinner at the neck,shoulder,and forward part of the case.

Thinner,it expands before the thicker part of the case does

The firing pin strike does drive the case forward during ignition,as far as it mechanically can go. Yes,an extractor CAN limit the travel...but,IMO,I would like tighter control over head clearance that the extractor provides.

As designed,the shoulder of a rimless bottleneck cartridge is the "anvil"that limits forward motion of the case against the shoulder area of the chamber.

So,lets look at this picture: The shoulder is against chamber steel.Its not moving.

The case head is forward,clear of the bolt face by whatever the head clearance is.

As pressure rises,the thin,forward part of the case expands(obturates) ,tight to the chamber.

Let me change the paradigm right here:

So,really what happens is the shoulder stays still,the CASE HEAD moves,stretching back to the bolt face.

You are correct if the case is nice and dry, the chamber is nice and dry, and there is a high coefficient of friction between both. The case neck stays put and the sidewalls have to stretch when internal pressures force the case head to the bolt face.

Now what if the case was lubricated?

Army Ordnance Magazine, March-April 1933

Automatic Firearms, Mechanical Principles used in the various types,

by J. S. Hatcher. Chief Smalls Arms Division Washington DC.

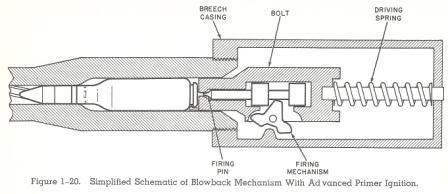

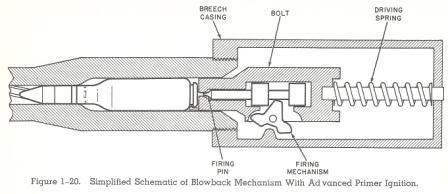

Retarded Blow-back Mechanism There is one queer thing, however, that is common to almost all blow-back and retarded blow-back guns, and that is that there is a tendency to rupture the cartridges unless they are lubricated. This is because the moment the explosion occurs the thin front end of the cartridge case swells up from the internal pressure and tightly grips the walls of the chamber. Cartridge cases are made with a strong solid brass head a thick wall near the rear end, but the wall tapers in thickness until the front end is quiet thin so that it will expand under pressure of the explosion and seal the chamber against the escape of gas to the rear. When the gun is fired the thin front section expands as intended and tightly grips the walls of the chamber, while the thick rear portion does not expand enough to produce serious friction. The same pressure that operates to expand the walls of the case laterally, also pushes back with the force of fifty thousand pounds to the square inch on the head of the cartridge, and the whole cartridge being made of elastic brass stretches to the rear and , in effect, give the breech block a sharp blow with starts it backward. The front end of the cartridge being tightly held by the friction against the walls of the chamber, and the rear end being free to move back in this manner under the internal pressure, either one of two things will happen. In the first case, the breech block and the head of the cartridge may continue to move back, tearing the cartridge in two and leaving the front end tightly stuck in the chamber; or, if the breech block is sufficiently retarded so that it does not allow a very violent backward motion, the result may simply be that the breech block moves back a short distance and the jerk of the extractor on the cartridge case stops it, and the gun will not operate.

However this difficultly can be overcome entirely by lubricating the cartridges in some way. In the Schwarzlose machine gun there is a little pump installed in the mechanism which squirts a single drop of oil into the chamber each time the breech block goes back. In the Thompson Auto-rifle there are oil-soaked pads in the magazine which contains the cartridges. In the Pedersen semiautomatic rifle the lubrication is taken care of by coating the cartridges with a light film of wax.

Blish Principle….There is no doubt that this mechanism can be made to operate as described, provided the cartridge are lubricated, …. That this type of mechanism actually opens while there is still considerable pressure in the cartridge case is evident from the fact that the gun does not operate satisfactorily unless the cartridges are lubricated.

Mechanisms that used greased cartridges and oilers were extensively used through WW2, but, not in the civilian world. These mechanisms have been out of service for so long, and they were never common in the hands of civilians, that they have been basically forgotten by the shooting community. Only those with an esoteric interest in antique mechanisms and the principles of operation even know about them. The very stupid and ignorant are clueless about them, and the operation of guns in general, and make up stories why they could not work.

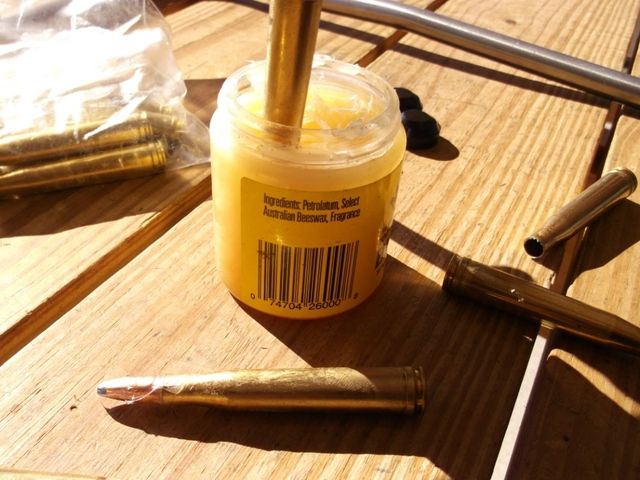

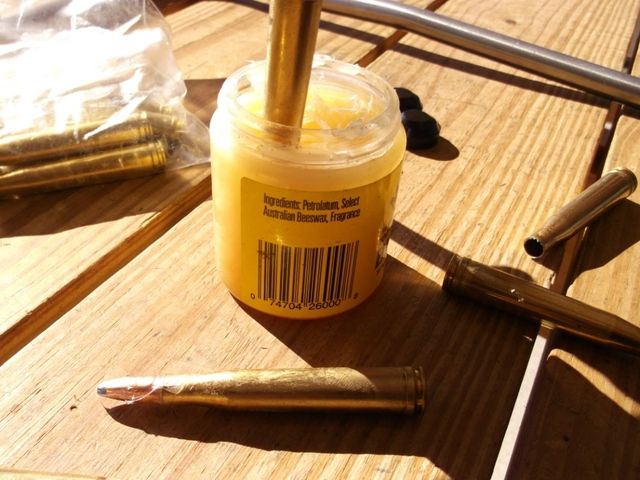

If the case is lubricated, breaking the friction between case and chamber, than instead of the case mouth fixing the cartridge case in place and causing case stretch, the case slides to the bolt face. The shoulder however, is blown out without stressing the case. This is something World Champion Benchrest shooters do when fireforming to achieve perfect, stress free cases.

This mechanism, the cartridge was greased or oiled. This is the Oerlikon mechanism, used by the American’s, British, Germans, and Japanese during WW2. Cases were pregreased in WW2, though after WW2, the US continued to use the gun with oilers. I have a Bullseye bud who stole an Oerlikon from the USAF, in Vietnam, and used it on his river barge. His Oerlikon used an oiler.

I have been greasing my rounds so that when I fired the cases, I don’t have sidewall stretch leading to case head separations. I also have been greasing my bullets, just as our fore fathers did during the days of cupronickel bullet jackets. I am convinced that my barrel cleanup is quicker and I have no detectable fouling.

This is a 300 H&H Magnum, which has a very shallow shoulder. Also, the base to shoulder distance is not controlled as the round headspaces on the rim. The end result of firing these things dry, in a dry chamber, is to stretch the heck out of the cases, leading to case head separations in a short number of firings. I lubricate the heck out of my new cases, fireform to fit the chamber, and then, I only bump the shoulder back a bit. Even greased, they shoot well.