I don't believe this is accurate. The numbers are correct, but these should be PSI and not CUP, which are not the same...and for which no formula of "conversion" exists.The current SAAMI pressure standards for .38 Special and .38 Special +P are 17,000 CUP and 18,500 CUP respectively.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.38 special +P ?

- Thread starter alfredr

- Start date

I followed your link and must say that it was an interesting and enjoyable read, and fun from a historical standpoint, but I would have trouble endorsing it also, so I suppose your anticipation is...correct?!I don't anticipate any more success here than I have had anywhere else but here goes.

Your article spends an awful lot of time talking about muzzle velocities and precious little time discussing maximum chamber pressure. It was a relief when I finally got to where pressure is even mentioned.

Certainly, we can't safely or logically classify the pressure of ammunition based solely on "rated" speed or even chrono tested speed? Anyone who has even dabbled with a chrono can quickly tell you the nearly endless different variables that can alter your chrono returns... everything from ambient temperature to the amount of solid roll-crimp that's been imparted on a loaded round, to say nothing of the vast differences you'll see from different firing platforms. It's never been a secret that you could pull two handguns from the same production line only moments apart and in consecutive serial numbered order and see differing chrono results from them with the "same" ammo.

You also never even lightly touch on the fact that Speer #8 has a well-earned, nearly "hall of fame" reputation in any (certainly halfway decent) handloading circles for some nearly 'what the hell were they thinking' loads published in it.

It's also not mentioned the colossal differences in the tools, equipment and intellectual advancement of pressure testing being done today from the old, retired methods used in the past.

Factory ammo these days is NOT made up from anybody's load data. Not any normal, full production ammo factory such as Federal or Winchester. They don't build their .38 Special+P rounds with "x.xx grains of xxx powder" Instead, they brew the load up according the the extremely advanced pressure testing equipment they use -- especially since the powder they are using is rarely exactly the same.

Winchester and Federal are members of SAAMI, so they build their products to meet the industry standard, the standard that was formalized by SAAMI. So when Winchester sells a product that says .38 Special+P on it... the bullet weight may be XX, constructed of XX in the shape and form of XX and it may go XX speed from any range of firearms, but you can bet that when it's in a properly spec'd chamber (built to a SAAMI specified industry standard), that loaded round will have a maximum pressure of 18,500 PSI at it's peak. No matter what you might get from it on your chrono in any firearm you launch it with.

And when they sell a box of ammo that is marked .38 Special, it will spit out results that will not exceed 17,000 PSI when it is pressure tested.

None of this really has anything to do with what Lee Jurras was doing and what the ammo companies were advertising in popular magazines 70-80 years ago and certainly nothing whatsoever with what Speer printed in some of their epic manuals that folks still reference whenever they want to make an unsuspecting newbie say "HOLY CRAP!"

The equipment, technology and capabilities to accurately and absolutely measure pressure NOW may make everything seem "weak" compared to yesterday, but it might be easier to wrap our heads around it if we simply admit that yesterday...if it "felt right" and "looked right", it got stamped "safe" and sent out the door.

Yes, SAAMI pressure NOW is 20,000. They lowered it for no reason other than on advice of counsel. When S&W introduced the 38 Special in the 1890s it was designed for 21,500 PSI and that was the standard until 1972 or 74 when they lowered it.

I believe I mentioned in my paper that there are specialty ammo makers who do push the envelope. I speak of mainstream (Winchester, Remington, etc.) +P ammo when I call it weak and unimpressive. C'mon, a 125 at 925 is a powerhouse? Give me a break.

I also mention in the text that the quality of the gun must be considered. Obviously if one has a cheap, broken down imported pistol it likely should not be fired at all. But such guns are never mentioned in these questions, the queries almost always center of various Colt and S&W revolvers. All of these are fine with +P in any amount.

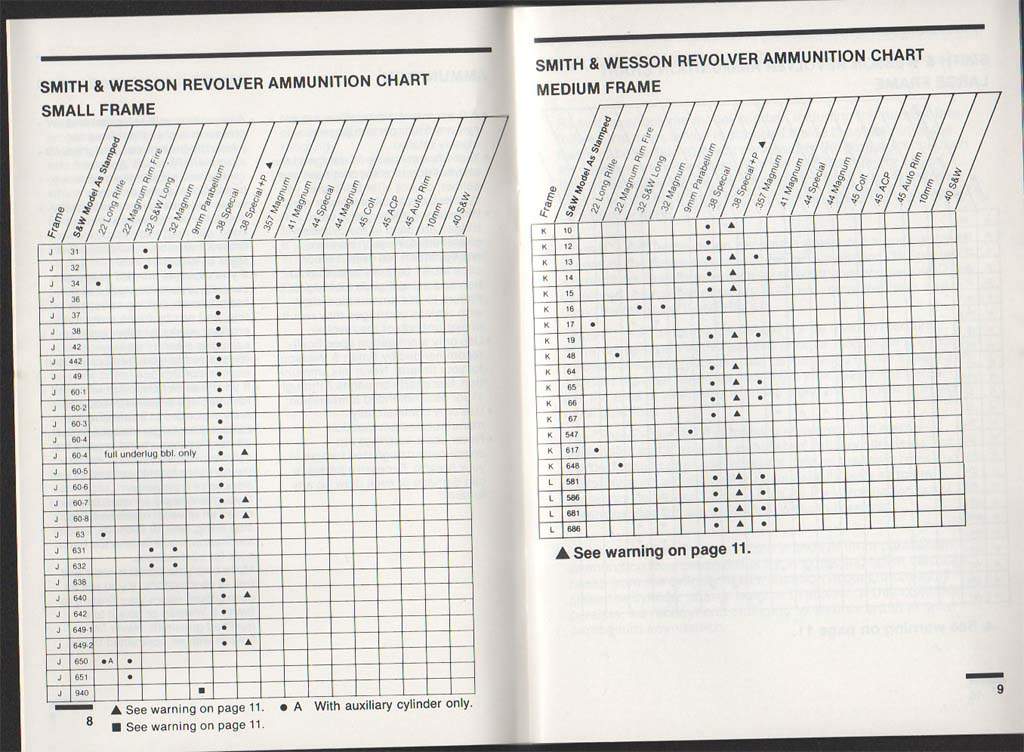

Again the notion of the beginning of model stamping (on S&Ws) is raised as a guideline. Why? What is different about the last gun made W/O the model number and the first one made with it? Nothing.

As for the observation that things are different now with new technology and all, then why weren't guns blowing up back in the good old days if those loads were so overpressure but we didn't know it?

I am not reading any criticism here that I have not already dealt with in the paper.

Like I said, I know I am tilting at windmills. You all are free to do what you think best. If you think that 125@925 load is going to blow up or wear out your S&W then by all means avoid it.

I believe I mentioned in my paper that there are specialty ammo makers who do push the envelope. I speak of mainstream (Winchester, Remington, etc.) +P ammo when I call it weak and unimpressive. C'mon, a 125 at 925 is a powerhouse? Give me a break.

I also mention in the text that the quality of the gun must be considered. Obviously if one has a cheap, broken down imported pistol it likely should not be fired at all. But such guns are never mentioned in these questions, the queries almost always center of various Colt and S&W revolvers. All of these are fine with +P in any amount.

Again the notion of the beginning of model stamping (on S&Ws) is raised as a guideline. Why? What is different about the last gun made W/O the model number and the first one made with it? Nothing.

As for the observation that things are different now with new technology and all, then why weren't guns blowing up back in the good old days if those loads were so overpressure but we didn't know it?

I am not reading any criticism here that I have not already dealt with in the paper.

Like I said, I know I am tilting at windmills. You all are free to do what you think best. If you think that 125@925 load is going to blow up or wear out your S&W then by all means avoid it.

To your point, I absolutely agree that none of these .38 Special +P is even going to be noticed by any modern handgun. To say that it's isn't likely to damage a modern handgun would be an understatement[/i] in my opinion.

Once again, however, you default to what damage may or may not happen from a given bullet weight at a given muzzle velocity. But that muzzle velocity is not a direct indicator of pressure. If you are any manner of a handloader, you know that to be true as a genuine basic principle.

Hyperbole-?! Perhaps. But they didn't have the means of getting up close & personal with what actually was happening inside their ammo in days long past.

Modern firearms from reputable manufacturers can handle far beyond the SAAMI spec for the cartridge they chamber. In fact, proof testing on each firearm by the SAAMI-member manufacturer is evidence of it.

An industry standard is just what it sounds like -- a standard. And the member companies stick to those standards. The manufacturers of the firearms and of the ammo.

Once again, however, you default to what damage may or may not happen from a given bullet weight at a given muzzle velocity. But that muzzle velocity is not a direct indicator of pressure. If you are any manner of a handloader, you know that to be true as a genuine basic principle.

SAAMI measures pressure and expresses it in PSI by using and translating feedback from transducers positioned in specific places. I wasn't there, but we may be suspect of where the transducers were placed when tested in 1890, or maybe even in the early 1970s.When S&W introduced the 38 Special in the 1890s it was designed for 21,500 PSI and that was the standard until 1972 or 74 when they lowered it.

Hyperbole-?! Perhaps. But they didn't have the means of getting up close & personal with what actually was happening inside their ammo in days long past.

Modern firearms from reputable manufacturers can handle far beyond the SAAMI spec for the cartridge they chamber. In fact, proof testing on each firearm by the SAAMI-member manufacturer is evidence of it.

An industry standard is just what it sounds like -- a standard. And the member companies stick to those standards. The manufacturers of the firearms and of the ammo.

Originally posted by SaxonPig

First of all, I'd very much like to see the source for this. However, even if we assume that it's correct, we must consider both the accuracy and reliability of 100+ year old pressure testing equipment and also that .38 Special was originally designed for black powder which has very different pressure characteristics than most modern smokeless powders.

You're making the mistake of equating pressure and velocity when they don't normally correlate. Buffalo Bore's standard pressure .38 Special ammo can equal the velocity of many +P loadings from other manufacturers even though it's lower pressure. The ways to do this aren't exactly majic or some sort of mystery, Buffalo Bore and other boutique ammo makers likely load their ammo right to the ragged edge of their pressure limits and use blends of multiple powder to quickly reach and maintain peak pressure.

The reason that larger ammo makers don't try to achive the velocities of boutique makers like Buffalo Bore is that the manner in which Tim Sundles and those like him are able to achieve they velocities they do requires very stringent quality control to remain safe (this is probably why boutique ammo is so much more expensive). I would not be surprised to learn that some, if not all, of the boutique ammo houses hand weigh the powder charges of their ammunition. Because the level of QC that must be maintained by boutique makers would be prohibitively time consuming and expensive for operations as large as Winchester, Remington, Federal, Hornady, or Speer, these makers instead choose not to used blended powders and to load their ammunition to a "safety margin" below the maximum pressure limit.

Not just the quality, but the age and condition as well. 19th century metallurgy was not the same as that of today or even that of the mid-20th century. While your 1942 vintage revolver may have suffered no apparent ill effects from 500 rounds of +P ammunition, you can not necessarily assume that the same would be true of a revolver made in 1902 or 1922 because the metallurgy of those times was not the same as it was in the 1940's.

As I said in my previous post, I think that the model number recommendation is rather conservative. That being said, I understand the logic of using model numbers as the dividing line. Without looking up the serial number in The Standard Catalog of Smith & Wesson, most people would not be able to distinguish between a M&P made in the 1920's and one made in the 1950's. The stamping of a model number is easily identified by people of even modest intelligence.

First of all, who said they were necessarilly overpressure? Innacuracy in pressure testing equipment can go both ways and what may have originally been thought to be 20K+ psi may have actually turned out to be less. Secondly, who said anything about guns blowing up? I doubt that a pre-WWII M&P would be likely to blow up even if shot with .38-44 high velocity ammo, but it would probably be shot loose in short order. Finally, how do we know that some guns didn't blow up? Unlike today, back when .38 ammo was supposedly loaded hotter, people couldn't simply fire up the computer and let hundreds, thousands, or even millions of people know about them having issues with a gun within minutes of the incident. If the old ammo was as hot as you claim and it wasn't causing problems, why then did SAAMI reduce the pressure limit as you claim they did?

Yes, SAAMI pressure NOW is 20,000. They lowered it for no reason other than on advice of counsel. When S&W introduced the 38 Special in the 1890s it was designed for 21,500 PSI and that was the standard until 1972 or 74 when they lowered it.

First of all, I'd very much like to see the source for this. However, even if we assume that it's correct, we must consider both the accuracy and reliability of 100+ year old pressure testing equipment and also that .38 Special was originally designed for black powder which has very different pressure characteristics than most modern smokeless powders.

I believe I mentioned in my paper that there are specialty ammo makers who do push the envelope. I speak of mainstream (Winchester, Remington, etc.) +P ammo when I call it weak and unimpressive. C'mon, a 125 at 925 is a powerhouse? Give me a break.

You're making the mistake of equating pressure and velocity when they don't normally correlate. Buffalo Bore's standard pressure .38 Special ammo can equal the velocity of many +P loadings from other manufacturers even though it's lower pressure. The ways to do this aren't exactly majic or some sort of mystery, Buffalo Bore and other boutique ammo makers likely load their ammo right to the ragged edge of their pressure limits and use blends of multiple powder to quickly reach and maintain peak pressure.

The reason that larger ammo makers don't try to achive the velocities of boutique makers like Buffalo Bore is that the manner in which Tim Sundles and those like him are able to achieve they velocities they do requires very stringent quality control to remain safe (this is probably why boutique ammo is so much more expensive). I would not be surprised to learn that some, if not all, of the boutique ammo houses hand weigh the powder charges of their ammunition. Because the level of QC that must be maintained by boutique makers would be prohibitively time consuming and expensive for operations as large as Winchester, Remington, Federal, Hornady, or Speer, these makers instead choose not to used blended powders and to load their ammunition to a "safety margin" below the maximum pressure limit.

I also mention in the text that the quality of the gun must be considered. Obviously if one has a cheap, broken down imported pistol it likely should not be fired at all. But such guns are never mentioned in these questions, the queries almost always center of various Colt and S&W revolvers. All of these are fine with +P in any amount.

Not just the quality, but the age and condition as well. 19th century metallurgy was not the same as that of today or even that of the mid-20th century. While your 1942 vintage revolver may have suffered no apparent ill effects from 500 rounds of +P ammunition, you can not necessarily assume that the same would be true of a revolver made in 1902 or 1922 because the metallurgy of those times was not the same as it was in the 1940's.

Again the notion of the beginning of model stamping (on S&Ws) is raised as a guideline. Why? What is different about the last gun made W/O the model number and the first one made with it? Nothing.

As I said in my previous post, I think that the model number recommendation is rather conservative. That being said, I understand the logic of using model numbers as the dividing line. Without looking up the serial number in The Standard Catalog of Smith & Wesson, most people would not be able to distinguish between a M&P made in the 1920's and one made in the 1950's. The stamping of a model number is easily identified by people of even modest intelligence.

As for the observation that things are different now with new technology and all, then why weren't guns blowing up back in the good old days if those loads were so overpressure but we didn't know it?

First of all, who said they were necessarilly overpressure? Innacuracy in pressure testing equipment can go both ways and what may have originally been thought to be 20K+ psi may have actually turned out to be less. Secondly, who said anything about guns blowing up? I doubt that a pre-WWII M&P would be likely to blow up even if shot with .38-44 high velocity ammo, but it would probably be shot loose in short order. Finally, how do we know that some guns didn't blow up? Unlike today, back when .38 ammo was supposedly loaded hotter, people couldn't simply fire up the computer and let hundreds, thousands, or even millions of people know about them having issues with a gun within minutes of the incident. If the old ammo was as hot as you claim and it wasn't causing problems, why then did SAAMI reduce the pressure limit as you claim they did?

If the old ammo was as hot as you claim and it wasn't causing problems, why then did SAAMI reduce the pressure limit as you claim they did?

I'll answer that one but then SP can defend himself and answer it as well. I am convinced they reduced the pressure limit simply because of liability and the lawyers. Litigation is so bloody expensive these days people and corporations go to even ridiculous lengths to avoid it.

I've used this argument before and will repeat it here. When I got into guns and reloading (late 1960s & early 1970s) the standard load for the 38 Special "service round" was a 158g RN cast bullet over 3.5g Bullseye. This delivered around 850 fps from a 6" barrel (like the M14) and closer to 800 fps from a 4" barrel (like a M10). I personally knew a number of shooters who had fired tens of thousands of rounds of that hand load and most of it through K-frame S&Ws. The first Star reloader I ever saw was set up to turn out that very load of 38 Special.

That level of performance is what I have recently chronographed from so called +P FBI loads, i.e. 800 fps from 4" barrels.

Today's 38 Special ammunition is wimpy. There's no other way to explain it and no other name for it.

Dave

Last edited:

Quote:

If the old ammo was as hot as you claim and it wasn't causing problems, why then did SAAMI reduce the pressure limit as you claim they did?

I'll answer that one but then SP can defend himself and answer it as well. I am convinced they reduced the pressure limit simply because of liability and the lawyers. Litigation is so bloody expensive these days people and corporations go to even ridiculous lengths to avoid it.

I still fail to understand why, if the old ammo was just fine and wasn't causing problems, the lawyers would have problems with it. A good lawyer isn't going to tell his client to make their product less marketable for no good reason. I'm sorry but I just don't buy that the ammo-makers and their lawyers suddenly turned into a bunch of spineless bed-wetters without some precipitating incident.

I've used this argument before and will repeat it here. When I got into guns and reloading (late 1960s & early 1970s) the standard load for the 38 Special "service round" was a 158g RN cast bullet over 3.5g Bullseye. This delivered around 850 fps from a 6" barrel (like the M14) and closer to 800 fps from a 4" barrel (like a M10). I personally knew a number of shooters who had fired tens of thousands of rounds of that hand load and most of it through K-frame S&Ws. The first Star reloader I ever saw was set up to turn out that very load of 38 Special.

That level of performance is what I have recently chronographed from so called +P FBI loads, i.e. 800 fps from 4" barrels.

Today's 38 Special ammunition is wimpy. There's no other way to explain it and no other name for it.

Was 850 from a 6" barrel your chronograph numbers or what was listed in the loading manual? The reason I ask is because Alliant still lists a very similar load as a standard pressure .38 Special (they currently list it with a SWC instead of a LRN bullet) and they now claim it to go 814fps from a 6" barrel.

http://www.alliantpowder.com/reloaders/RecipePrint.aspx?gtypeid=1&weight=158&shellid=26&bulletid=30&bdid=52

My suspicion is that the old loads never were as hot as you and SaxonPig seem to think that they were, it's just that improvements in both accuracy and availability of chronographs have made the ammo makers and loading manuals more honest over the years.

While it's not been my style to say "prove it or it ain't true", I have to say that I thoroughly believe that the whole "lawyer" and "liability" card is a much, much over-played couple of buzzwords we've used in gun circles for years.

We refer to Ruger's obnoxious propensity for writing a full owner's manual right on the barrel as a knee-jerk, blanket reaction by lawyers stemming from a loss in a liability case. That is a solid, real-word example.

However, I've never seen citations of successful liability suits leveled against ammo makers for catastrophic events. (along these same lines, I have never seen a single citation for civil or criminal suits brought against handloaders to hand off their home brew reloads for their long time buddy to shoot, where he blows his face off and his widow and children sue the handloader for everything he's got)

These get parroted out endlessly, but I've still never seen a citation.

Certainly, some must exist. I'm not burning calories going and looking for them, but it sure seems to me that this is not an epidemic. But it sure does get referred to as if it's a horrendously large legal issue for anyone involved in this industry.

Is that the reality?

Does every ammo maker get sued each third week because of some ammo-related incident? Is every fourth handloader that shares his hand-rolled fodder losing his house (and car, motorcycle, guns, dogs and boat) in a massive civil suit that I'm simply not reading about?

Are these cases any relation to the literally countless THOUSANDS of slain police officers from the 1950s through the 1980's who were found dead at the scene with six empty cartridge cases neatly placed in their breast pocket because they were too slow to reload in a gunfight and they fell back to their level of training that had a range officer barking at them to police their brass?!

We refer to Ruger's obnoxious propensity for writing a full owner's manual right on the barrel as a knee-jerk, blanket reaction by lawyers stemming from a loss in a liability case. That is a solid, real-word example.

However, I've never seen citations of successful liability suits leveled against ammo makers for catastrophic events. (along these same lines, I have never seen a single citation for civil or criminal suits brought against handloaders to hand off their home brew reloads for their long time buddy to shoot, where he blows his face off and his widow and children sue the handloader for everything he's got)

These get parroted out endlessly, but I've still never seen a citation.

Certainly, some must exist. I'm not burning calories going and looking for them, but it sure seems to me that this is not an epidemic. But it sure does get referred to as if it's a horrendously large legal issue for anyone involved in this industry.

Is that the reality?

Does every ammo maker get sued each third week because of some ammo-related incident? Is every fourth handloader that shares his hand-rolled fodder losing his house (and car, motorcycle, guns, dogs and boat) in a massive civil suit that I'm simply not reading about?

Are these cases any relation to the literally countless THOUSANDS of slain police officers from the 1950s through the 1980's who were found dead at the scene with six empty cartridge cases neatly placed in their breast pocket because they were too slow to reload in a gunfight and they fell back to their level of training that had a range officer barking at them to police their brass?!

Got this from Handloads.com for a 158g lead bullet.

3.6 gr Bullseye 910 fps 1.42" Fed 100 Alliant

"Alliant" at the end means the information/data came from Alliant.

I pose this as a counter to Sevens comments.

If the old factory ammo, or the handloads some of us are referring to were in fact higher in pressure than the old testing indicated...they still were used in the hundreds of thousands and didn't destroy or wear out guns. And is it not a fact that the SAMMI standard pressure for the 38 Special gone down?

Dave

3.6 gr Bullseye 910 fps 1.42" Fed 100 Alliant

"Alliant" at the end means the information/data came from Alliant.

I pose this as a counter to Sevens comments.

If the old factory ammo, or the handloads some of us are referring to were in fact higher in pressure than the old testing indicated...they still were used in the hundreds of thousands and didn't destroy or wear out guns. And is it not a fact that the SAMMI standard pressure for the 38 Special gone down?

Dave

Last edited:

Okay, I'm not entirely sure how that counters what I said, but I'm more than happy to discuss it.

It's my understanding (keep in mind that I am here to LEARN, and always eager to do so) that SAAMI standards "back in the day" were CUP standards.

It's my understanding that CUP can not be simply "converted" to PSI. CUP was the process they had, it was a good process and it was cutting edge... at the time. When the piezo process (and PSI results) were developed, they found that the pressure inside the round was peaking in a manner that they were not able to see with the older technology.

NEW standards (PSI, and not CUP) were developed and agreed upon, and set by SAAMI, and as an industry standard, were then agreed upon by all participating entities. Those groups include the publishers and testers of load data, ammo manufacturers and of course... firearms manufacturers.

Again, for the Nth time, if the argument is "Hey, these firearms can handle loads that are beyond SAAMI spec and they certainly could back then because the ammo was hotter" then again, for the Nth time, I am in full agreement.

However, the spec is what the spec is. SAAMI has their name next to it, but let's not make the mistake of having a picture in our mind of some knucklehead lawyer in a twill suit, 125 lbs soaking wet, thick glasses and a hairy crustache, sitting behind his master computer plotting against all shooters and gun lovers, wearing his "SAAMI President" name tag, who is setting a bunch of arbitrarily low maximum pressure standards on all the world's most loved cartridges.

It's my understanding (keep in mind that I am here to LEARN, and always eager to do so) that SAAMI standards "back in the day" were CUP standards.

It's my understanding that CUP can not be simply "converted" to PSI. CUP was the process they had, it was a good process and it was cutting edge... at the time. When the piezo process (and PSI results) were developed, they found that the pressure inside the round was peaking in a manner that they were not able to see with the older technology.

NEW standards (PSI, and not CUP) were developed and agreed upon, and set by SAAMI, and as an industry standard, were then agreed upon by all participating entities. Those groups include the publishers and testers of load data, ammo manufacturers and of course... firearms manufacturers.

Again, for the Nth time, if the argument is "Hey, these firearms can handle loads that are beyond SAAMI spec and they certainly could back then because the ammo was hotter" then again, for the Nth time, I am in full agreement.

However, the spec is what the spec is. SAAMI has their name next to it, but let's not make the mistake of having a picture in our mind of some knucklehead lawyer in a twill suit, 125 lbs soaking wet, thick glasses and a hairy crustache, sitting behind his master computer plotting against all shooters and gun lovers, wearing his "SAAMI President" name tag, who is setting a bunch of arbitrarily low maximum pressure standards on all the world's most loved cartridges.

Another point that may be relevant is to bring to the top again the idea that while it takes pressure to make velocity, the two are not, nor have ever been linear. There's SO MUCH that goes on inside a cartridge.

Using the .44 Magnum as an example... if you handload a round with a 240 grain jacketed bullet and you give it a full charge of slow-burning H110 powder (from a published load) and give it a firm roll crimp, you can expect that load to return a proper "magnum" velocity in line with performance .44 Magnum ammo you might spend $30-$50 a box for at the gun store. That H110 will pretty much -FILL- all the space in that case.

Now if you take that same .44 Magnum case and use the same bullet and this time, you leave the H110 on the shelf and instead, you grab the bottle of Titegroup, you can build a load using half or less of the amount of powder as you did with H110. You can even build a "safe" load with it, as long as you are diligent and you don't even THINK about trying to fill that case with this fast-burning powder.

You must use a sensible charge weight here because the powder burns quickly and you have enough room in that case to EASILY double charge the round--or more. The powder burns FAST, the pressure peak comes QUICKLY.

If you load that to a maximum published charge, you will still have a HUGE open space in the cartridge. It will work. And it will return a PSI at or near 36,000 PSI which is SAAMI max for the .44 Magnum.

And you know what else it will do?

It will fling that bullet (remember: SAME MAX PRESSURE!) at 200-300 less feet per second.

Why? Because the powder's burn rate isn't optimal for the round. It peaks far too early. It is a "safe" round because the publishers of the load data have tested it thoroughly, but it gives you all the max pressure, all the wear & tear, and not near as much "performance." It will save you a few pennies in buying powder.

So... what would happen if you used more of that space in there, and poured in more Titegroup?! Pretty sure you'd blow the revolver to pieces. Top-strap opened like a busted fence plank, cylinder in at least two pieces. Unfired rounds sitting in adjacent chambers looking innocent, ready to blow up THE NEXT revolver you might want to put them in to.

Using the .44 Magnum as an example... if you handload a round with a 240 grain jacketed bullet and you give it a full charge of slow-burning H110 powder (from a published load) and give it a firm roll crimp, you can expect that load to return a proper "magnum" velocity in line with performance .44 Magnum ammo you might spend $30-$50 a box for at the gun store. That H110 will pretty much -FILL- all the space in that case.

Now if you take that same .44 Magnum case and use the same bullet and this time, you leave the H110 on the shelf and instead, you grab the bottle of Titegroup, you can build a load using half or less of the amount of powder as you did with H110. You can even build a "safe" load with it, as long as you are diligent and you don't even THINK about trying to fill that case with this fast-burning powder.

You must use a sensible charge weight here because the powder burns quickly and you have enough room in that case to EASILY double charge the round--or more. The powder burns FAST, the pressure peak comes QUICKLY.

If you load that to a maximum published charge, you will still have a HUGE open space in the cartridge. It will work. And it will return a PSI at or near 36,000 PSI which is SAAMI max for the .44 Magnum.

And you know what else it will do?

It will fling that bullet (remember: SAME MAX PRESSURE!) at 200-300 less feet per second.

Why? Because the powder's burn rate isn't optimal for the round. It peaks far too early. It is a "safe" round because the publishers of the load data have tested it thoroughly, but it gives you all the max pressure, all the wear & tear, and not near as much "performance." It will save you a few pennies in buying powder.

So... what would happen if you used more of that space in there, and poured in more Titegroup?! Pretty sure you'd blow the revolver to pieces. Top-strap opened like a busted fence plank, cylinder in at least two pieces. Unfired rounds sitting in adjacent chambers looking innocent, ready to blow up THE NEXT revolver you might want to put them in to.

Got this from Handloads.com for a 158g lead bullet.

3.6 gr Bullseye 910 fps 1.42" Fed 100 Alliant

"Alliant" at the end means the information/data came from Alliant.

That's a whopping 0.1gr over the current maximum per Alliant in the link I posted previously. I notice, however, that the data from Handloads.com specifies Federal 100 primers while Alliant's current data specifies CCI 500 primers. Given the well known fact that changing primers can change pressure, the switch in components could easily explain Alliant's changing their data.

Alliant still lists a very similar load as a standard pressure .38 Special (they currently list it with a SWC instead of a LRN bullet) and they now claim it to go 814fps from a 6" barrel.

Sevens,

I was simply countering your info from Alliant with another claim from the same manufacturer that fit my "ancient" history (LOL) better. I edited my post to better reflect what I was trying to say. Sorry to have come across as a (expletive deleted).

Dave

So what is the "warning on page 11?" They include it for all the models that are .357 magnum also, not just the .38 Specials.

And has anyone just asked SAAMI about the old versus new pressure ratings?

Or the firearms manufacturers?

Or the ammunition manufacturers?

And if anyone has asked, were they open and forthcoming with answers, or otherwise?

Or just shot some of the old ammunition in the new measuring equipment to see what it does produce as far as pressures?

And there must be some strong correlation between chamber pressure and velocity of the bullet, with the same bullet weight, even if it is not entirely linear, as Sevens says.

Thanks for everything so far. Inquiring minds want to know, but don't have the time to do the research themselves.

alfredr

And has anyone just asked SAAMI about the old versus new pressure ratings?

Or the firearms manufacturers?

Or the ammunition manufacturers?

And if anyone has asked, were they open and forthcoming with answers, or otherwise?

Or just shot some of the old ammunition in the new measuring equipment to see what it does produce as far as pressures?

And there must be some strong correlation between chamber pressure and velocity of the bullet, with the same bullet weight, even if it is not entirely linear, as Sevens says.

Thanks for everything so far. Inquiring minds want to know, but don't have the time to do the research themselves.

alfredr

I've literally been following this question in this forum since my join date in 1999 and also on other forums. I have never - never - seen absolutely ironclad, definitive answers but scores of passionately held opinions often held forth as fact. And, the number of people entering this debate on the side of 38+P being too weak to hurt any gun is shockingly small when observed over time. In this debate, the term "usual suspects" takes on real meaning. Why definitive answers are so hard to come by, I don't know, but passionately held opinions are rampant. Otherwise, there would be a "Sticky" on the subject.And has anyone just asked SAAMI about the old versus new pressure ratings?

Or the firearms manufacturers?

Or the ammunition manufacturers?

And if anyone has asked, were they open and forthcoming with answers, or otherwise?

I've seen entire threads seemingly dedicated to the argument that since +P did not seem to hurt a pre-1958 K-frame, therefore it can't hurt someone's old J-frame Airweight.

Last edited:

I just can't stop beating my head against the wall, I guess.

Just for fun, here's a S&W ad from before WW II stating that the K frame M&P revolver can be fired with 38/44 ammo. The 38/44 load was a 158 lead SWC at 1125-1140 FPS and operated at far, far higher chamber pressures than current mainstream +P. Colt also advertised their D frame (Police Positive Special) as 38/44 capable (also pictured below). Comments from the doubters when I show these usually go "Well, they didn't know any better at the time" or "They didn't really mean it."

A retired cop I communicated with said he used 1,000 rounds of 38/44 he found in the department ammo locker through his issue M10 in the late 1950s with no effect. Not sure I would have done that, but he did, and if the 38/44 ammo didn't faze that K frame, current +P would be a lollipop by comparison.

Here's an ad for ammo marketed by S&W in the late 1960s and early 1970s (I think the time frame is thus). How about that 125 JHP at 1380 FPS? Doubters say "Well, they lied about the velocity." Granted, all ammo makers fudged a bit back before every Tom, Dick and Harry had a chronograph, but in my experience the inflation was on the order of 5% or so. Assuming a 10% inflated claim, that still leaves it at over 1200 FPS leaving the current +P at 925 in the dust. The lawyers told them to stop marketing truly hot ammo because of crappy imported guns floating around. So they started making weak and wimpy stuff and labeled it +P to fool the public into thinking one could buy high performance ammo.

As for the often repeated statement that there is no relationship between chamber pressure and velocity, hogwash. Pressure is what creates velocity. It's the pressure within the chamber that pushes the projectile out the barrel. The higher the pressure, the higher the velocity. Certainly manipulations can be made with powders and primers to a certain extent, but basically, if you want the bullet to go faster, you must raise the chamber pressure. The 38 goes 730 FPS at 16,500 PSi and the 357 pushes the same bullet to 1,300 FPS but running at 34,000 PSI. Obviously pressure and velocity are not in a straight line, and pressure goes up faster than does velocity. But there is most definitely a cause and effect relationship between velocity and chamber pressure. If velocities are reduced, like when the major ammo companies lowered the standard 158 38 Special from 840 to 730 FPS, so are pressures.

Just for fun, here's a S&W ad from before WW II stating that the K frame M&P revolver can be fired with 38/44 ammo. The 38/44 load was a 158 lead SWC at 1125-1140 FPS and operated at far, far higher chamber pressures than current mainstream +P. Colt also advertised their D frame (Police Positive Special) as 38/44 capable (also pictured below). Comments from the doubters when I show these usually go "Well, they didn't know any better at the time" or "They didn't really mean it."

A retired cop I communicated with said he used 1,000 rounds of 38/44 he found in the department ammo locker through his issue M10 in the late 1950s with no effect. Not sure I would have done that, but he did, and if the 38/44 ammo didn't faze that K frame, current +P would be a lollipop by comparison.

Here's an ad for ammo marketed by S&W in the late 1960s and early 1970s (I think the time frame is thus). How about that 125 JHP at 1380 FPS? Doubters say "Well, they lied about the velocity." Granted, all ammo makers fudged a bit back before every Tom, Dick and Harry had a chronograph, but in my experience the inflation was on the order of 5% or so. Assuming a 10% inflated claim, that still leaves it at over 1200 FPS leaving the current +P at 925 in the dust. The lawyers told them to stop marketing truly hot ammo because of crappy imported guns floating around. So they started making weak and wimpy stuff and labeled it +P to fool the public into thinking one could buy high performance ammo.

As for the often repeated statement that there is no relationship between chamber pressure and velocity, hogwash. Pressure is what creates velocity. It's the pressure within the chamber that pushes the projectile out the barrel. The higher the pressure, the higher the velocity. Certainly manipulations can be made with powders and primers to a certain extent, but basically, if you want the bullet to go faster, you must raise the chamber pressure. The 38 goes 730 FPS at 16,500 PSi and the 357 pushes the same bullet to 1,300 FPS but running at 34,000 PSI. Obviously pressure and velocity are not in a straight line, and pressure goes up faster than does velocity. But there is most definitely a cause and effect relationship between velocity and chamber pressure. If velocities are reduced, like when the major ammo companies lowered the standard 158 38 Special from 840 to 730 FPS, so are pressures.