I personally wouldn't necessarily consider an overload of powder. I would look further to debris in the bolt area. I have seen things like this happen from something as simple as a piece of walnut shell stuck in the primer hole. I would treat it as a freak thing and move on after checking for obvious problems.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

30-06 Bolt opening problem

- Thread starter Bucksnort1

- Start date

Let me ask a question. It may sound kind of stupid, even. You mentioned that the bolt turned and opened easily, but couldn't be extracted. Seems odd, ordinarily, unlocking the bolt pulls the case backward some, so that it should extract easily.

I guess that the question is, are you sure that dirt or something else didn't jam the bolt?

__________________

don’t take me so seriously, or get irritated with my spelling.

Ordinarily, unlocking the bolt pulls the case backward some

Briandg, that is only ordinary for my rifles, all of my rifles have a cam extract, I open the bolt and then the bolt cams back and the case comes with it. And then the ‘and then’. I have crushed a few case heads meaning I shorted the distance from the cup above the web to the case head; reducing the case head thickness increases extractor clearance meaning the bolt will cam back before the extractor contacts the case head. When I lift the bolt I know I am going to have trouble looking cool because every shooter at the range should know when I bump the bolt back with unnecessary effort I have a case that that has all of its useful life used up with one firing.

Last edited:

As one of those added measure's, I would clean the chamber, mop or chamber brush

Not saying it is but I have had some extraction issues and the chamber cleaning stopped it.

mil surplus until recently that I did not have to do that, so it was new to have to specifically address it in cleaning.

Not saying it is but I have had some extraction issues and the chamber cleaning stopped it.

mil surplus until recently that I did not have to do that, so it was new to have to specifically address it in cleaning.

And then there are the 'too proud', those are the reloaders that assume every thing. They do not know the weight of the components before they start. They do not understand the last opportunity to check their work is before they pull the trigger.

I have an electronic scale that is fast, I am not too proud to weight loaded ammo; it is like measure the length of a case after firing without measuring the length before firing; if I did not know the weight of the components I would be wasting my time weighing after loading.

And then there is the 4 grains, I have stuck cases in chambers, I have rendered cases scrap with one firing and I was pleased. I know, you are all confused so I will take the time to explain why I was pleased. The brass I was using had the ability to expand because it was soft. Of the cases I have wrecked none of them were fired with only 4 grains over maximum.

At one time reloaders developed loads with skill and knowledge, today there is the Internet. Why doesn't a reloader know the diameter of the case head before they start? If the OP had a problem with too much powder there should be a difference in the diameter of the case heads.

I know; no one sorts brass and no one measures before and again after.

F. Guffey

I have an electronic scale that is fast, I am not too proud to weight loaded ammo; it is like measure the length of a case after firing without measuring the length before firing; if I did not know the weight of the components I would be wasting my time weighing after loading.

And then there is the 4 grains, I have stuck cases in chambers, I have rendered cases scrap with one firing and I was pleased. I know, you are all confused so I will take the time to explain why I was pleased. The brass I was using had the ability to expand because it was soft. Of the cases I have wrecked none of them were fired with only 4 grains over maximum.

At one time reloaders developed loads with skill and knowledge, today there is the Internet. Why doesn't a reloader know the diameter of the case head before they start? If the OP had a problem with too much powder there should be a difference in the diameter of the case heads.

I know; no one sorts brass and no one measures before and again after.

F. Guffey

Strafer Gott

New member

The scale is the most suspicious. Loosing calibration is simply not acceptable! Bad tool! In my view, you would replace the scale post haste. Pardon me if it's already been said. Metrology rules.

The scale is the most suspicious. Loosing calibration is simply not acceptable! Bad tool! In my view, you would replace the scale post haste. Pardon me if it's already been said. Metrology rules.

I have more than one scale; I have more than one set of check weights. If I had one set it would be a balance beam type. And yes; it has already been said, and now we wait to find out if he gets check weights or another scale or develops discipline when reloading. He could decide to do all three.

F. Guffey

It was, he believes, 0.4 grains, and not 4.0 grains. But unless he validates with a 55 grain check weight (match bullet is close enough) I can't say his scale linearity isn't off. The 0.4 grain loss of zero doesn't impress me as particularly bad. I've see a number of scale strain gauges with that much hysteresis. It would settle back out, but a lot of scales now seem to have a minimum change requirement programmed in before they will register that a change has occurred. It's a strategy to stabilize the display, but it makes trickling loads impossible on the scales that settle too quickly.

The bolt moving freely suggests no high pressure indentation of the ejector tunnel or other such factor. I think I would have turned the bolt up, but knocked the case out from the muzzle with a brass rod and hammer to avoid stress on the extractor. I would then look for shiny spots on the case. Whatever is trapping it, even if it is debris, should leave a mark where it was stuck.

The bolt moving freely suggests no high pressure indentation of the ejector tunnel or other such factor. I think I would have turned the bolt up, but knocked the case out from the muzzle with a brass rod and hammer to avoid stress on the extractor. I would then look for shiny spots on the case. Whatever is trapping it, even if it is debris, should leave a mark where it was stuck.

It's been a while since I loaded 30-06 with IMR4350, but from what I recall, it would be mighty tough to overcharge one, as I seem to remember 4350 loads filling into the case neck, and the high end loads were compressed. I was suing Speer's max published load back then which was 57gr for a 180gr bullet. .4 gr is irrelevant with 4350.

Loads worked up near max are not safe to shoot in a different gun without working up again, but this sounds more like a starting load that should be safe in anything. I doubt factory ammo is tested in every gun known to man, though most would consider it safe in any good condition gun chambered for it.

Since these seem to function fine in one gun, and not the other, I'd look at other issues that cause stuck cases that are related to the gun, such as irregularities in the chamber. I would also ask if cases were trimmed to length and how deep the bullet was seated. If your case is too long, your chamber throat can squeeze it tight on the bullet, or if the bullet is too far out, you could be seating it when you close the bolt.

Loads worked up near max are not safe to shoot in a different gun without working up again, but this sounds more like a starting load that should be safe in anything. I doubt factory ammo is tested in every gun known to man, though most would consider it safe in any good condition gun chambered for it.

Since these seem to function fine in one gun, and not the other, I'd look at other issues that cause stuck cases that are related to the gun, such as irregularities in the chamber. I would also ask if cases were trimmed to length and how deep the bullet was seated. If your case is too long, your chamber throat can squeeze it tight on the bullet, or if the bullet is too far out, you could be seating it when you close the bolt.

The scale is the most suspicious. Loosing calibration is simply not acceptable! Bad tool! In my view, you would replace the scale post haste. Pardon me if it's already been said. Metrology rules.

Scales do it all the time, that is one reason they have the zero. You re-zero, if suspicious confirm with the calibration weight.

I did compare the cratered case with the others. The only difference is the cratered primer. The primer was not pushed out of the pocket to any degree.

The difference when compared with other primers; the cratered primer was not like the other cases that had pushed out/protruding primers. Does that mean you had primers that were protruding?

F. Guffey

Bucksnort1

New member

Guffey,

There were no protruding primers in any of the fired rounds including the one with the crater.

I've come up with another possibility. What if I used a large rifle magnum primer? Anything is possible but I doubt it here because all the primers are S&B. I don't have any S&B large rifle magnum primers. I don't think S&B makes a large rifle magnum primer. I guess I should say I've never seen them at Cabela's.

There were no protruding primers in any of the fired rounds including the one with the crater.

I've come up with another possibility. What if I used a large rifle magnum primer? Anything is possible but I doubt it here because all the primers are S&B. I don't have any S&B large rifle magnum primers. I don't think S&B makes a large rifle magnum primer. I guess I should say I've never seen them at Cabela's.

Bucksnort1

New member

Unclenick is correct, it is .4 grains, not 4 grains. I have a new Cabela's digital scale I've never used. I can't get to it now because it's packed and under tons of boxes waiting for our move to Arizona, later summer. When I move to AZ, I will begin using the Cabela's scale.

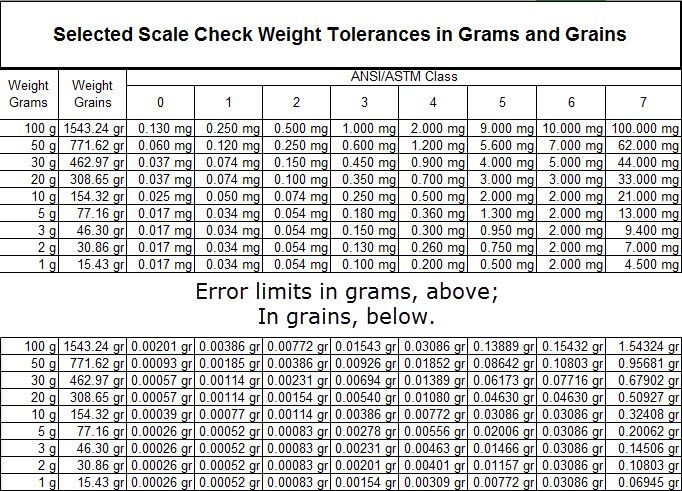

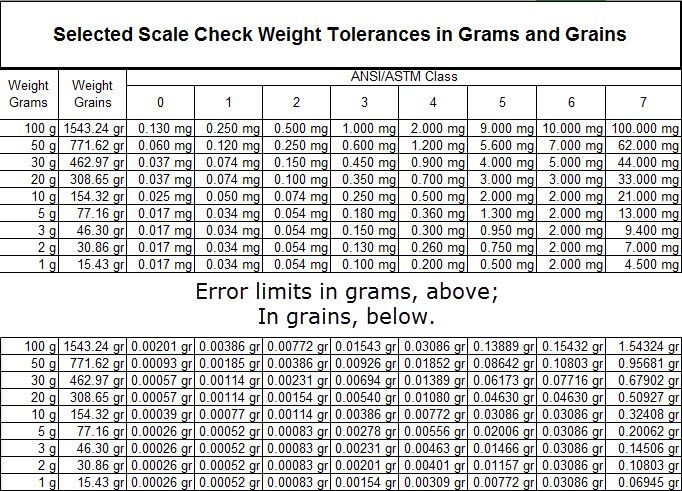

RC20, My Lyman scale has a calibration weight of 20 grams. I check it periodically and I checked it a few minutes ago. It reads, 20.03 grams. While showing my grandson some reloading of these cartridges, I checked the weight of one of the 165 bullets. I don't recall the exact weight but it was 165 grains + a fraction of a grain.

TimSr, you are correct. The 4350 powder in the -06 case, it fills to where the case neck begins.

There are no shiny areas on the case indicating where it may have hung.

RC20, My Lyman scale has a calibration weight of 20 grams. I check it periodically and I checked it a few minutes ago. It reads, 20.03 grams. While showing my grandson some reloading of these cartridges, I checked the weight of one of the 165 bullets. I don't recall the exact weight but it was 165 grains + a fraction of a grain.

TimSr, you are correct. The 4350 powder in the -06 case, it fills to where the case neck begins.

There are no shiny areas on the case indicating where it may have hung.

Could be the check weight class, though. Class 7, the least expensive kind, would have a 0.033 gram tolerance for a 20 gram weight. I took a screen capture of my Excel file on this data, below. That said, I think class 6 are what are usually supplied for powder scales. I just don't know that you can always count on it.

P

Duffy, regarding your post on bolt camming, my own 700 cams into the action but I'm not sure if it also pushes outward. I hesitated to suggest it. Since I neck size, that rifle sometimes requires a bit of force to load. Without knowing the age of that brass, it's tempting to scrap the got and start fresh, even though I know that most of it could only have three or so loadings.

I keep saying that these component are far too inexpensive to take risks with.

Duffy, regarding your post on bolt camming, my own 700 cams into the action but I'm not sure if it also pushes outward. I hesitated to suggest it. Since I neck size, that rifle sometimes requires a bit of force to load. Without knowing the age of that brass, it's tempting to scrap the got and start fresh, even though I know that most of it could only have three or so loadings.

I keep saying that these component are far too inexpensive to take risks with.

If you look at SAAMI drawings for rimless bottleneck rifle cartridges, you see they often allow the cases to be slightly longer than a minimum chamber. The assumption is bolt closing will expand the brass outward, so the limit is put where the compression between head and shoulder runs out of room to accommodate the resulting fattening of the case. This is done because of the unilateral dimensions used to establish critical limits. Manufacturers make the cases much closer to the minimum length.

Bucksnort1,

This is most peculiar. To clarify: Nothing is shiny on the brass, but the rim is bent like the 308 Winchester in the photo?

It that's true, the brass is hanging on somewhere, somehow, because the rim bend would not be produced if the bolt was hanging up somewhere and couldn't be pulled back. There is really no alternative explanation I can think of.

You could try marking a number of cases with a spray can of layout dye (Magic Marker works, but is a pain to apply all over and to a number of cases) before firing to see more clearly where it scuffs off.

One other thought occurs to me: Is it possible you had some rounds where the bullet wasn't fully seated? If a bullet jams into the lands of a gun's throat, I've seen that raise pressure 20%, and more is possible with some gun and bullet combinations. It shouldn't get to proof load pressures, but never say never.

Most Remingtons are known for having long throats, so I don't expect the above problem, but every once in awhile you hear of a production gun of one brand or another getting past inspection after only a roughing reamer was used to cut the chamber. These chambers don't have a proper throat, so bullet jump is very short. A load that is normal in another gun could jam the throat in them. I don't know how you seated your bullets, but it might be worth checking which ones are longest, putting Magic Marker one a long bullet and chambering and extracting it unfired to look for rifling marks on the seated bullet.

Bucksnort1,

This is most peculiar. To clarify: Nothing is shiny on the brass, but the rim is bent like the 308 Winchester in the photo?

It that's true, the brass is hanging on somewhere, somehow, because the rim bend would not be produced if the bolt was hanging up somewhere and couldn't be pulled back. There is really no alternative explanation I can think of.

You could try marking a number of cases with a spray can of layout dye (Magic Marker works, but is a pain to apply all over and to a number of cases) before firing to see more clearly where it scuffs off.

One other thought occurs to me: Is it possible you had some rounds where the bullet wasn't fully seated? If a bullet jams into the lands of a gun's throat, I've seen that raise pressure 20%, and more is possible with some gun and bullet combinations. It shouldn't get to proof load pressures, but never say never.

Most Remingtons are known for having long throats, so I don't expect the above problem, but every once in awhile you hear of a production gun of one brand or another getting past inspection after only a roughing reamer was used to cut the chamber. These chambers don't have a proper throat, so bullet jump is very short. A load that is normal in another gun could jam the throat in them. I don't know how you seated your bullets, but it might be worth checking which ones are longest, putting Magic Marker one a long bullet and chambering and extracting it unfired to look for rifling marks on the seated bullet.

Bucksnort1

New member

Unclenick,

Sorry, I did not intend to mislead you with the photo of the cratered cases. I failed to notice the indentation on the heads of the cases in the photo. My case did not have any indentations, if I recall correctly. I say, "if I recall correctly" because I believe I've packed that case with the last of my reloading "stuff" for my move to Arizona so I won't be able to do anything with it for some months or with any of my reloading for that matter.

You know, anything is possible but it's not probable I did an incorrect seating with that case or any case in that group of ten. As I said earlier, I used a case gauge to check each case then checked overall length with a digital caliper. Finally, after loading the ten rounds, I insert each round in the box with the bullet up then, I look across the top to see if there are any cartridges either taller or shorter than the others. For these ten rounds, they looked perfect.

Now, I don't want loaders to think I'm perfect when it comes to reloading and that I don't make mistakes but I sure do make one heck of an effort to put out near perfect loads.

When I'm settled in AZ, I will perform your blackening procedure then post the results.

Sorry about the delay on this but the move to AZ is important. I just can't wait to live in 117 degree weather. The good news about 117 degree weather is, you don't have to shovel it. Actually, I'm very excited about the move.

Sorry, I did not intend to mislead you with the photo of the cratered cases. I failed to notice the indentation on the heads of the cases in the photo. My case did not have any indentations, if I recall correctly. I say, "if I recall correctly" because I believe I've packed that case with the last of my reloading "stuff" for my move to Arizona so I won't be able to do anything with it for some months or with any of my reloading for that matter.

You know, anything is possible but it's not probable I did an incorrect seating with that case or any case in that group of ten. As I said earlier, I used a case gauge to check each case then checked overall length with a digital caliper. Finally, after loading the ten rounds, I insert each round in the box with the bullet up then, I look across the top to see if there are any cartridges either taller or shorter than the others. For these ten rounds, they looked perfect.

Now, I don't want loaders to think I'm perfect when it comes to reloading and that I don't make mistakes but I sure do make one heck of an effort to put out near perfect loads.

When I'm settled in AZ, I will perform your blackening procedure then post the results.

Sorry about the delay on this but the move to AZ is important. I just can't wait to live in 117 degree weather. The good news about 117 degree weather is, you don't have to shovel it. Actually, I'm very excited about the move.

condor bravo

New member

Right on Buck, your move to Arizona. Probably some of the population there would like to trade the 117 degrees for some of the shoveling stuff, at least for a while. If you will be in the Phoenix area you will also be experiencing the monsoons that come rolling up from Mexico in the afternoons. You will see the black clouds approaching from miles away and then suddenly you are hit with the blast furnace of high velocity dust and you never know where your patio umbrella will end up. And then the drenching downpours come down but by the next morning everything will again be hot and dry. Like no other place on earth.

But for the record, I still think the 10th round was the result of an overload somehow sneaking in. You seem meticulous in your reloading though.

But for the record, I still think the 10th round was the result of an overload somehow sneaking in. You seem meticulous in your reloading though.

Bucksnort1

New member

Condor,

I'm now of a mind to believe you are correct on the over loaded 10th round. The primer is the tell tale evidence. For the 10th round, there was no noticeable difference in recoil because we were using my new Caldwell Lead Sled with 25 pounds of weights.

I've been to AZ in the summer and I've been to Kandahar, Afghanistan, as a DoD civilian, in the summer. They are similar in weather except the one big difference is the when the monsoon hits in Kandahar, summer is over (usually around early October). Our move to AZ involves being around the grandchildren, mostly. For me there are other advantages such as being able to shoot all year round with mostly no weather worries and to fly fish all year.

I almost forgot about two seasons of wonderful dove hunting.

I'm now of a mind to believe you are correct on the over loaded 10th round. The primer is the tell tale evidence. For the 10th round, there was no noticeable difference in recoil because we were using my new Caldwell Lead Sled with 25 pounds of weights.

I've been to AZ in the summer and I've been to Kandahar, Afghanistan, as a DoD civilian, in the summer. They are similar in weather except the one big difference is the when the monsoon hits in Kandahar, summer is over (usually around early October). Our move to AZ involves being around the grandchildren, mostly. For me there are other advantages such as being able to shoot all year round with mostly no weather worries and to fly fish all year.

I almost forgot about two seasons of wonderful dove hunting.