Dixie Gunsmithing

Moderator Emeritus

Well, I'm stumped, as it was working before it was taken apart. You have all the old extractor, so there's nothing that fell into the trigger guard housing.

I'll look at the take-down and service manual again tomorrow. There is something I must be missing, but I'll re-read what I did this morning, and let you know.

Edit:

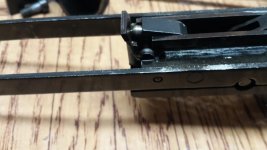

I found what I was looking for, and I am wondering if all these model 100's had these. The early versions, at least, had what was known as a trigger lock lever, which set in front of the hammer, and just behind the T-shaped metal piece that makes the back of the magazine well in the trigger guard. It is a camming piece, and is spring loaded. It toggles on a pin that's driven through the front of the trigger guard and in front of the hammer pin, and there should be a hole in those steel arms for it at the front. This is supposed to block the trigger, if the bolt isn't closed. If your gun does not have this, then it should fire, even if the bolt is not all the way closed.

The hammer is held back by the hammer hook or disconnector, pinned to the rear of the trigger, for semi-auto fire. It should move freely, and is spring loaded. Also, with the safety off, the trigger should move easy, and check for its spring tension. When you release the trigger, after it re-cocks, the hammer hook or disconnector should pull off the notch on the hammer, and allow the sear hook to catch on the forward sear notch just below where the hammer hook catches on the hammer. If it does not have the trigger lock lever, then it should fire, unless something is fouling the action of the hammer hook (disconnector). If it does have the trigger lock lever, look for it to be fouled, and not moving properly.

What was throwing me, is that the parts drawings do not show the trigger lock lever, but the NRA disassembly guide does. However, it shows a drawing of the older model, which has the machined hammer hook, and not the bent sheet metal one. I knew these had a trigger lock lever, which blocks the trigger if the bolt isn't closed, but I don't see this on some photos I've seen, nor on parts lists. If it is in yours, it will sit right in front of the hammer, held by a thru-pivot pin. There is another pin in it's side, with a pan head on it, and a plunger and spring in the front of it. The cam block has a lever arm that reaches down into the trigger guard to block the front of the trigger from working. Check for this.

I'll look at the take-down and service manual again tomorrow. There is something I must be missing, but I'll re-read what I did this morning, and let you know.

Edit:

I found what I was looking for, and I am wondering if all these model 100's had these. The early versions, at least, had what was known as a trigger lock lever, which set in front of the hammer, and just behind the T-shaped metal piece that makes the back of the magazine well in the trigger guard. It is a camming piece, and is spring loaded. It toggles on a pin that's driven through the front of the trigger guard and in front of the hammer pin, and there should be a hole in those steel arms for it at the front. This is supposed to block the trigger, if the bolt isn't closed. If your gun does not have this, then it should fire, even if the bolt is not all the way closed.

The hammer is held back by the hammer hook or disconnector, pinned to the rear of the trigger, for semi-auto fire. It should move freely, and is spring loaded. Also, with the safety off, the trigger should move easy, and check for its spring tension. When you release the trigger, after it re-cocks, the hammer hook or disconnector should pull off the notch on the hammer, and allow the sear hook to catch on the forward sear notch just below where the hammer hook catches on the hammer. If it does not have the trigger lock lever, then it should fire, unless something is fouling the action of the hammer hook (disconnector). If it does have the trigger lock lever, look for it to be fouled, and not moving properly.

What was throwing me, is that the parts drawings do not show the trigger lock lever, but the NRA disassembly guide does. However, it shows a drawing of the older model, which has the machined hammer hook, and not the bent sheet metal one. I knew these had a trigger lock lever, which blocks the trigger if the bolt isn't closed, but I don't see this on some photos I've seen, nor on parts lists. If it is in yours, it will sit right in front of the hammer, held by a thru-pivot pin. There is another pin in it's side, with a pan head on it, and a plunger and spring in the front of it. The cam block has a lever arm that reaches down into the trigger guard to block the front of the trigger from working. Check for this.

Last edited: