and it allows the choke to be larger in diameter so it can be stronger.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

whats the purpose of extended chokes????

- Thread starter whitearrow

- Start date

ya lost me thereand it allows the choke to be larger in diameter so it can be stronger.

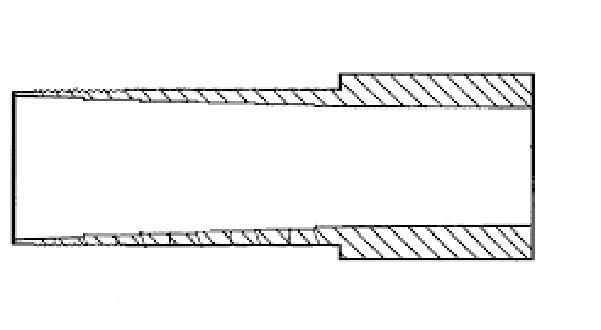

If the choke is internal the outer diameter of the choke is restricted to the inner diameter of the machined portion of the barrel. If the choke is extended the OD of the choke can be equal to the OD of the barrel. Larger diameter and same ID of the choke equals greater wall thickness right where the stress is greatest, which equals a stronger choke.

If you are talking about pressure at the muzzle, that has dropped since the first 12" or so in the barrel. The external choke certainly can't be any thinker than the outside diameter of the barrel, else folks shooting guns with two barrels would have issues.

The three main benefits as mentioned above are ease of changing, ease of identification, and protection if you rest them on your foot or similar. After fixed chokes, I prefer extended over flush, but I do admit that extended choke on a SxS just look WRONG..........

The three main benefits as mentioned above are ease of changing, ease of identification, and protection if you rest them on your foot or similar. After fixed chokes, I prefer extended over flush, but I do admit that extended choke on a SxS just look WRONG..........

I'm not. The extra strength comes in handy when trying to get a load of shot, especially steel shot, to squeeze a narrow opening at high speed.If you are talking about pressure at the muzzle, that has dropped since the first 12" or so in the barrel.

The external choke certainly can't be any thinker than the outside diameter of the barrel, else folks shooting guns with two barrels would have issues.

True. That's why I said:

If the choke is extended the OD of the choke can be equal to the OD of the barrel.

buckhorn_cortez

New member

If the choke is internal the outer diameter of the choke is restricted to the inner diameter of the machined portion of the barrel. If the choke is extended the OD of the choke can be equal to the OD of the barrel. Larger diameter and same ID of the choke equals greater wall thickness right where the stress is greatest, which equals a stronger choke.

What you've shown in your illustration is a continuous tapered choke. Not all chokes are that design. Some manufacturers make a taper / straight choke where the choke tapers from the breach end to the maximum constriction and then will have a straight portion to the muzzle.

What is interesting in patterning chokes, and what most people don't look for, is clumping of shot where multiple pellets will hit in nearly the same place. This causes holes in the pattern that are large enough that clay pigeons or smaller birds, like doves, can be missed as the shot will simply pass by them.

Unless you carefully pattern chokes, including: marking 30-inch, 20-inch, and 10-inch circles around the pattern; count the pellets; and look for, and mark the holes in the patterns you won't be fully aware of choke performance differences.

Simply shooting a pattern and visually evaluating it won't tell you much of anything about choke performance.

Unless you carefully pattern chokes, including: marking 30-inch, 20-inch, and 10-inch circles around the pattern; count the pellets; and look for, and mark the holes in the patterns you won't be fully aware of choke performance differences.

Simply shooting a pattern and visually evaluating it won't tell you much of anything about choke performance.

Visually evaluating it will let you see any holes in the two-dimensional view, but since a pattern is a 3-D conical shape anyway, counting holes or similar is a waste of time.

If your chokes are true, your barrels properly regulated, and you use good performing ammo and do your part, the target, bird or clay, gets hit.

Last year in prep to shoot 5 stand with a 20 ga I discovered that on the pattern board I liked the pattern of a Fed cheap 7/8oz , 7-1/2 shot, better than the patterns of cheap Fed #8 shot, shot a AA 7/8 oz, #8 Sporting load and it was no better than the 5.00 Fed. Long story short, shoot on paper to find out what your gun does with different load/chokes. The 7-1/2 shot loads had a very good pattern it the center ( about 12" dia ) and was pretty widely dispersed outside the 12" center. The size 8 shot loads were widely dispersed with several holes a clay bird would have flown thru. This was with IC chokes at 25 yards.

I may try some AA with 7-1/2 shot if I can find them. I also put in a full choke and tried the 7-1/2 load on trap. Worked very well the first round, next time I tried them not so much.

I think the Fed loads with the IC chokes would be good on doves out to 30 yards.

I may try some AA with 7-1/2 shot if I can find them. I also put in a full choke and tried the 7-1/2 load on trap. Worked very well the first round, next time I tried them not so much.

I think the Fed loads with the IC chokes would be good on doves out to 30 yards.

I have to disagree, big time. I was seeking an 80 yard goose gun/load combination, and I came up with two; one in 12 and another in 10 gauge. Only by statistically comparing data - and counting pellet holes - can you know if you are going the right way with changes. And before the know it all don't take long shots crowd chimes in, I practiced on high speed clay pigeons at 75 yards. My cripple rate was way below everyone else's. I liked tall shots. I was serious there for a while.Visually evaluating it will let you see any holes in the two-dimensional view, but since a pattern is a 3-D conical shape anyway, counting holes or similar is a waste of time.

At 80 yards, you will have a LONG shot string - can you tell which of those pellets hit first and the rest later? Can you tell where the gaps were in those initial pellets and which ones filled in those gaps later? I can't and do not k ow anyone who can without some very expensive camera and test gear.

I did not know which pellet(s) got there first, nor did I care. The relative speed of the shot string vs that of the target is such that you get enough pellets to deliver a killing load IF your patterns are tight enough. Plus, the target and the shot string are three dimensional, so that also increases the hit probability. I did measure the shot string a la Bob Brister's method, and I did a 3 dimensional analysis back then. Shot string really wasn't that bad with buffered loads and barely slit shot cups.

All my work was with copper and nickel plated lead shot, and then the non toxic regs came along and rendered it all moot. I am curious what could be achieved with the tungsten alloy stuff, but I no longer have the energy to do the work or put in the practice.

All my work was with copper and nickel plated lead shot, and then the non toxic regs came along and rendered it all moot. I am curious what could be achieved with the tungsten alloy stuff, but I no longer have the energy to do the work or put in the practice.