You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

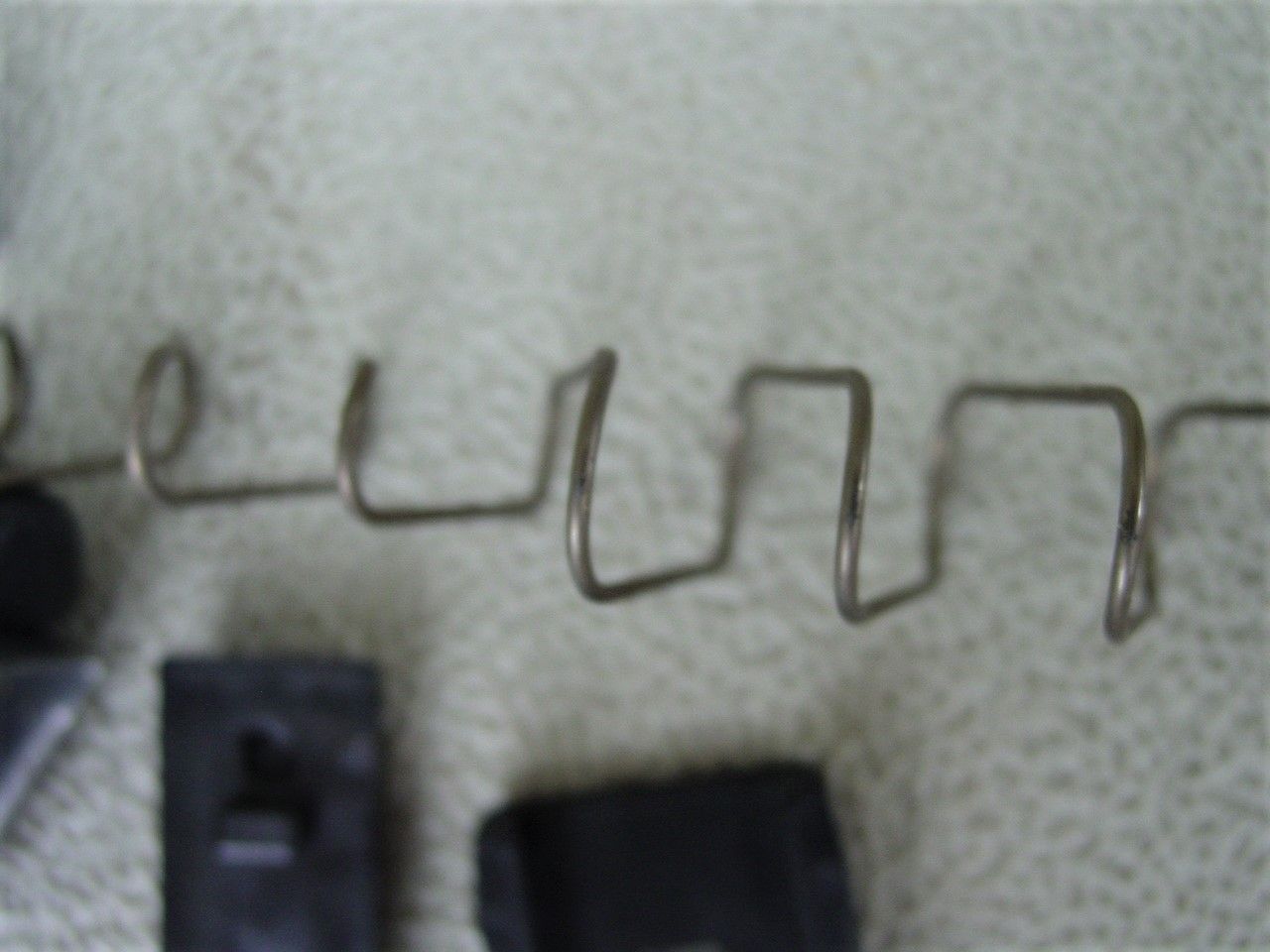

What in the world can do this to a magazine?

- Thread starter pgb205

- Start date

JohnSA. My apology for not making my point clear. Ejection is job of the extractor and ejector. It doesn't need the magazine follower to kick out the brass. When people fixate on the wrong area trying to fix the issue and never really solve the problem, theoretical discussions become practical problems. That is what I meant to say.

Never meant to say you made things up, and no second guess on your intentions either. Internet is full of claims and stories, including yours and mine. I go by what I learned at school and my own experience.

Anyway, both you and I believe what we believe, and we are here to provide inputs to help the OP. Let him decide what to do. We have done our duties. I'd stop here to mind my own business.

-TL

Sent from my SM-G930T using Tapatalk

Never meant to say you made things up, and no second guess on your intentions either. Internet is full of claims and stories, including yours and mine. I go by what I learned at school and my own experience.

Anyway, both you and I believe what we believe, and we are here to provide inputs to help the OP. Let him decide what to do. We have done our duties. I'd stop here to mind my own business.

-TL

Sent from my SM-G930T using Tapatalk

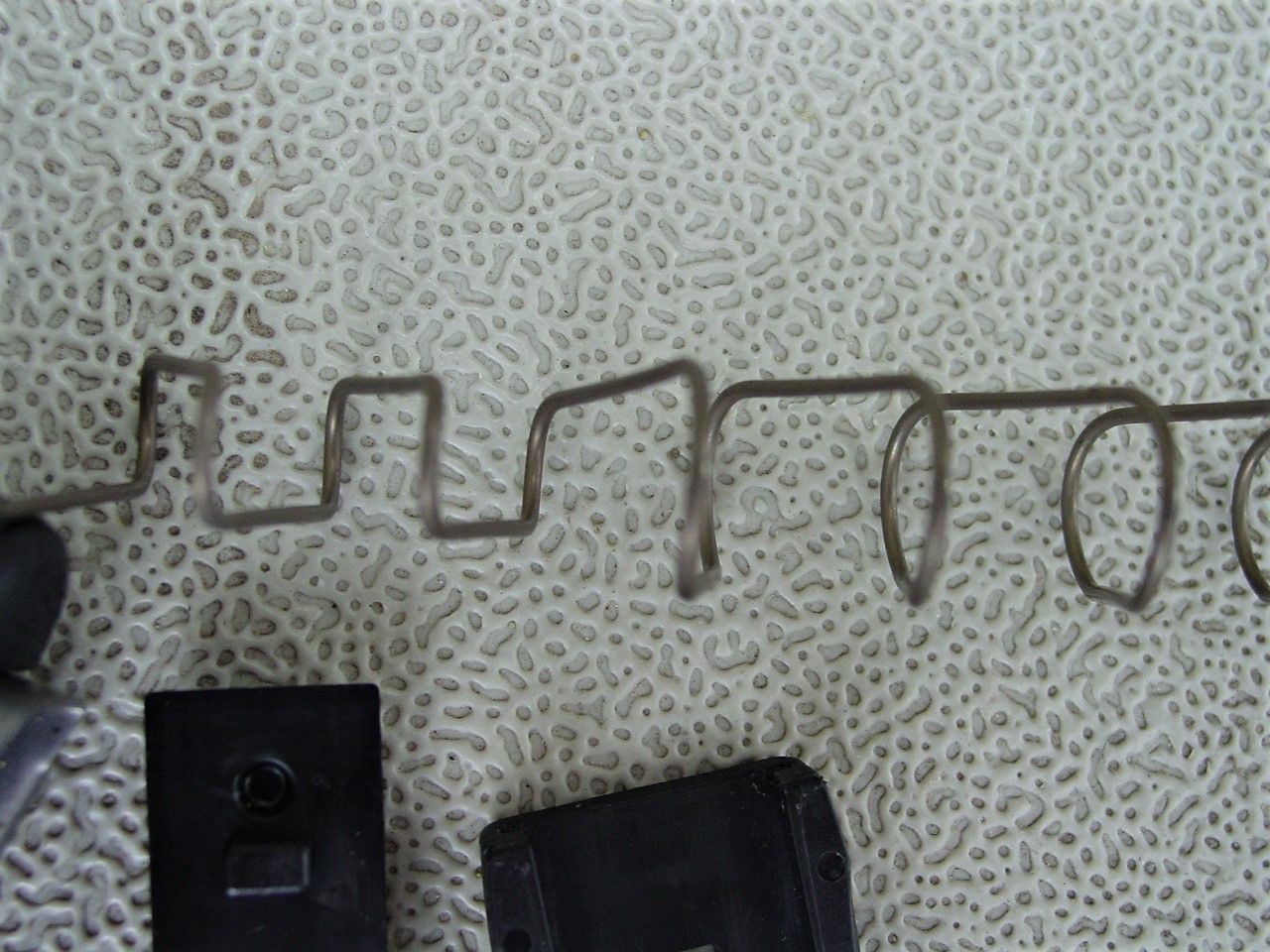

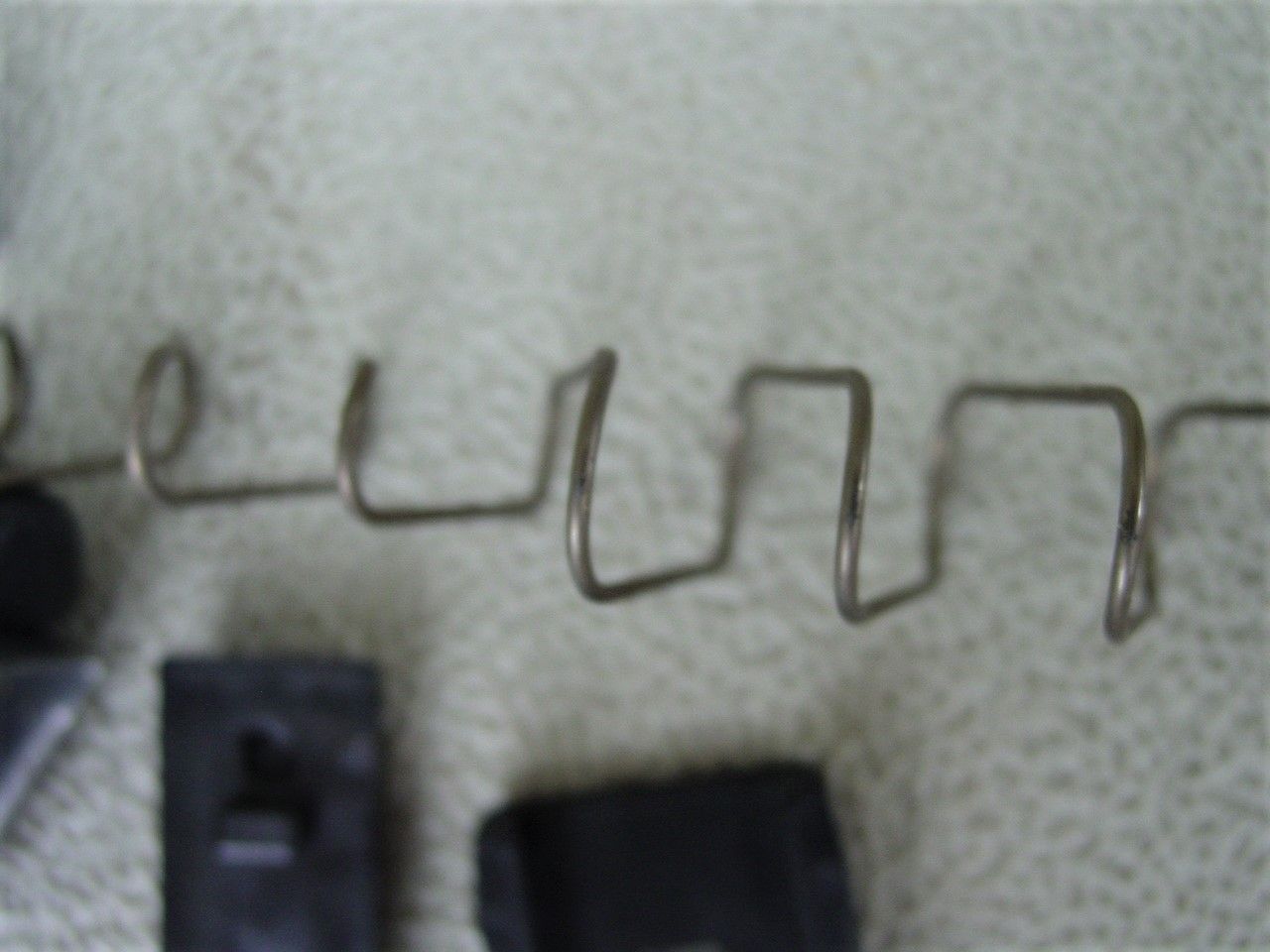

A single coil is bent at about 90* from norm. It looks like a crazy mess, but examine it carefully. This happened while the spring was compressed. No other way.

The spring was defective. Bad heat treat? Age? Damage? We'll never know.

When the spring was fully compressed, the coils did not stack up as normal but rather were forced either fore or aft in the mag at the weak spot. As the spring tension was released, the weak spot allowed the spring to gain some friction from the inside of the magazine which further promoted the spring losing proper shape. Didn't happen instantly, it was a process. If you had taken the spring out months ago, I bet it would not have looked straight, but rather had a bend at the 6th coil.

As the spring continued to lose strength at the weak spot, the other portions of the spring were still strong. The weak spot work hardened until instead of just not stacking up normally, that coil lost any ability to act as a spring at that point. The spring bound, got bent, and you see the result.

The spring was defective. Bad heat treat? Age? Damage? We'll never know.

When the spring was fully compressed, the coils did not stack up as normal but rather were forced either fore or aft in the mag at the weak spot. As the spring tension was released, the weak spot allowed the spring to gain some friction from the inside of the magazine which further promoted the spring losing proper shape. Didn't happen instantly, it was a process. If you had taken the spring out months ago, I bet it would not have looked straight, but rather had a bend at the 6th coil.

As the spring continued to lose strength at the weak spot, the other portions of the spring were still strong. The weak spot work hardened until instead of just not stacking up normally, that coil lost any ability to act as a spring at that point. The spring bound, got bent, and you see the result.

Last edited:

RAfiringline

New member

I think that spring had a defective spot created either by defective metal or during the coiling process. During use, the defective spot finally failed, the follower wasn't pushed up, when the mag was disassembled the spring wound around its weak area.

deputy tom

New member

There is a You-tube video showing this exact thing. I read about faulty Shield magazine springs a few years ago. tom.

https://www.youtube.com/watch?v=UVdPPBCnOQ0

https://www.youtube.com/watch?v=UVdPPBCnOQ0

polyphemus

New member

My guess would be that the point at which the smaller size spring meets the larger one was weak and that it failed during compression after"quite a few times" of compress/expand cycles.I'm curious what can do this to a magazine spring and how can I avoid it?

Regular spring replacement is a prudent rule of maintenance .

Walt Sherrill

New member

The Shield magazine only has one spring. But spring failure is the likely source of the problem.

(While I've seen and owned guns that had multiple recoil springs, I don't think I've ever encountered dual springs in a standard single- or double-stack magazine.)

(While I've seen and owned guns that had multiple recoil springs, I don't think I've ever encountered dual springs in a standard single- or double-stack magazine.)

To be fair, looking back at your posts, nothing in them implies that I was making things up or that my motives were less than pure and I shouldn't have made it seem like you had.Never meant to say you made things up, and no second guess on your intentions either.

It's possible that an underlying issue with the extractor or ejector could be masked by the action of the magazine on the extracted brass. The point I was trying to make was that an ejection problem being tied to a magazine issue is possible. In at least some pistols, the design depends on the action of the magazine on the brass for consistent ejection. I don't know if that "feature" is intentional or not.Ejection is job of the extractor and ejector. It doesn't need the magazine follower to kick out the brass.

Deputy Tom's post #25 shows the problem and the nature of it. It's a weakness in the design of the spring and the mag.

The spring will only do (take on) that right angle kink when released from the mag. Mainly because it can't do it while in the mag. But while in the mag, the smaller diameter of the portion of the spring that is at the top of the mag as it narrows towards the follower can become caught on the larger diameter coil when compressed or as it un-compresses. From the top of the spring the the first 6 coils are about the same diameter. The 7th coil is larger by a bit allowing the 6th to become tangled in the 7th.

Simple thing. The magazine tapers sharply towards the top. The spring must be sized to accommodate this. So one coil can be come caught in the next larger one. The right angle kink only appears when when released from the mag. But notice in the vid that it's caught up inside the mag when he has to pull it out of the mag towards the end of the video.

tipoc

The spring will only do (take on) that right angle kink when released from the mag. Mainly because it can't do it while in the mag. But while in the mag, the smaller diameter of the portion of the spring that is at the top of the mag as it narrows towards the follower can become caught on the larger diameter coil when compressed or as it un-compresses. From the top of the spring the the first 6 coils are about the same diameter. The 7th coil is larger by a bit allowing the 6th to become tangled in the 7th.

Simple thing. The magazine tapers sharply towards the top. The spring must be sized to accommodate this. So one coil can be come caught in the next larger one. The right angle kink only appears when when released from the mag. But notice in the vid that it's caught up inside the mag when he has to pull it out of the mag towards the end of the video.

tipoc

Walt Sherrill

New member

tipoc said:Simple thing. The magazine tapers sharply towards the top. The spring must be sized to accommodate this. So one coil can be come caught in the next larger one. The right angle kink only appears when when released from the mag. But notice in the vid that it's caught up inside the mag when he has to pull it out of the mag towards the end of the video.

Don't think that really explains what we can see...

I don't think most magazine springs have a taper, (either in shape or metal diameter) which is what you seem to describe. Most of them stay in contact with the sides of the magazine throughout their travel.

If the spring has a defect in the metal and that portion of the spring FAILS while in the magazine, the steel in that area can bend and twist in very unpredictable ways. But because the spring is somethat constrained by the stronger metal case of the mag tube, it can still move around, but is now free to mave in ways the mag tube can't control.

I think the spring twisted and/or kinked due to metal failure, and somewhat knotted itself up inside the mag tube.

- That knotting and twisting caused the spring to also push against the sides of the tube rather than just the top and bottom, and that in turn caused the follower to be stuck partway down the mag tube -- it sort of expanded (twisted/knotted) and plugged things up and held the follower in an unexpected position. It couldn't do anything else.

polyphemus

New member

Whether most magazines don't have different diameter springs,OP's happens toI don't think most magazine springs have a taper, (either in shape or metal diameter)

have one that that does.Metal fatigue can cause the smaller D.section to collapse into the larger one and when removed show the 90* bend visible in his

photo.MecGar magazines also have smaller D. top loops to fit in the step follower.

Whether most magazines don't have different diameter springs,OP's happens to

have one that that does.Metal fatigue can cause the smaller D.section to collapse into the larger one and when removed show the 90* bend visible in his

photo.MecGar magazines also have smaller D. top loops to fit in the step follower.

Metal fatigue is a possibility. Incorrect assembly another. This would be with the recoil spring inserted backwards by an inattentive individual.

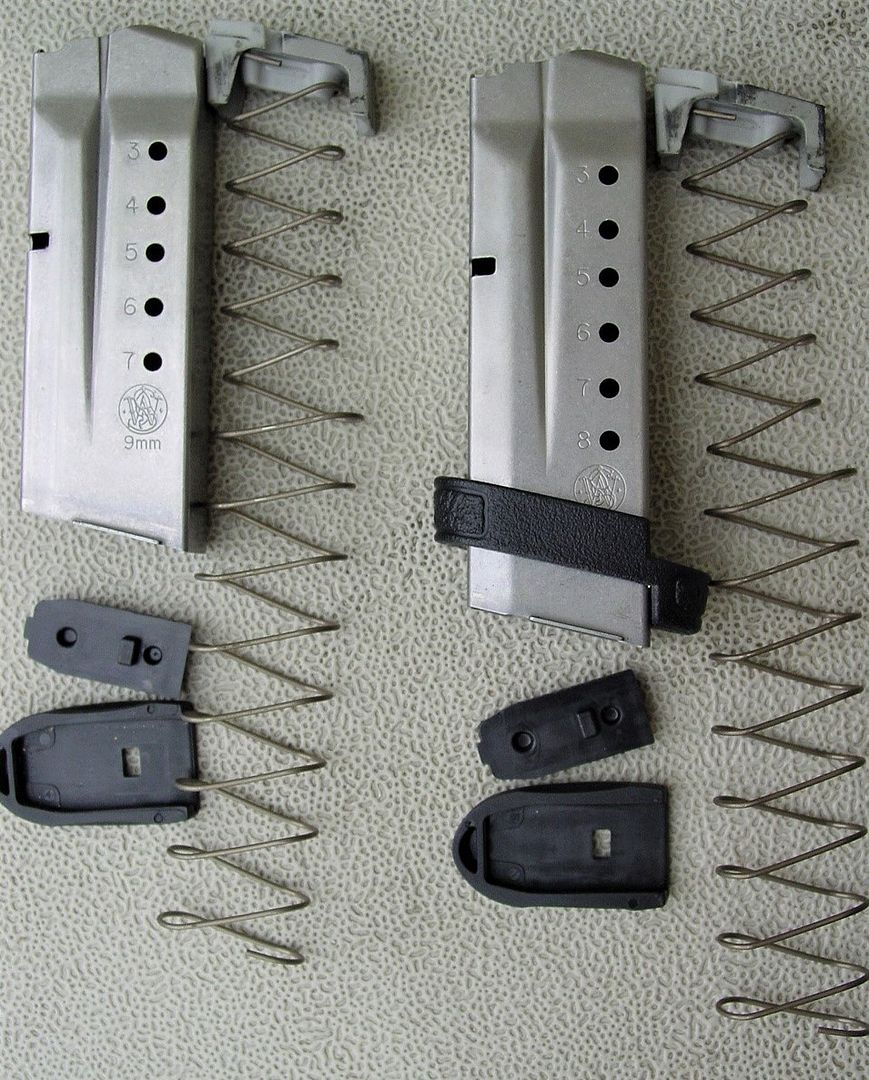

Below are the 7 and 8 round mags side by side. Same spring in both and identical follower.

tipoc

Last edited:

Both the length of the coils and the width of the coils are different. The length of the longer coil being 1.125" vs. .900 for the shorter coil. The width being .510 for the longer vs. .365 for the shorter. This allows for the one to nestle comfortably in the other when compressed. Also allows for one to hang up on the other in rare circumstances.

This is not a common occurrence. It's never happened to me. But clearly it happens.

tipoc

This is not a common occurrence. It's never happened to me. But clearly it happens.

tipoc

@tipoc. So here is the thing. I remember disassembling and cleaning several of my magazines a while back. Don't remember if this mag was one of those worked on, but it's entirely possible.

When you say "recoil spring inserted backwards" do you mean up/down or left/right dimension was not correctly setup?

When you say "recoil spring inserted backwards" do you mean up/down or left/right dimension was not correctly setup?

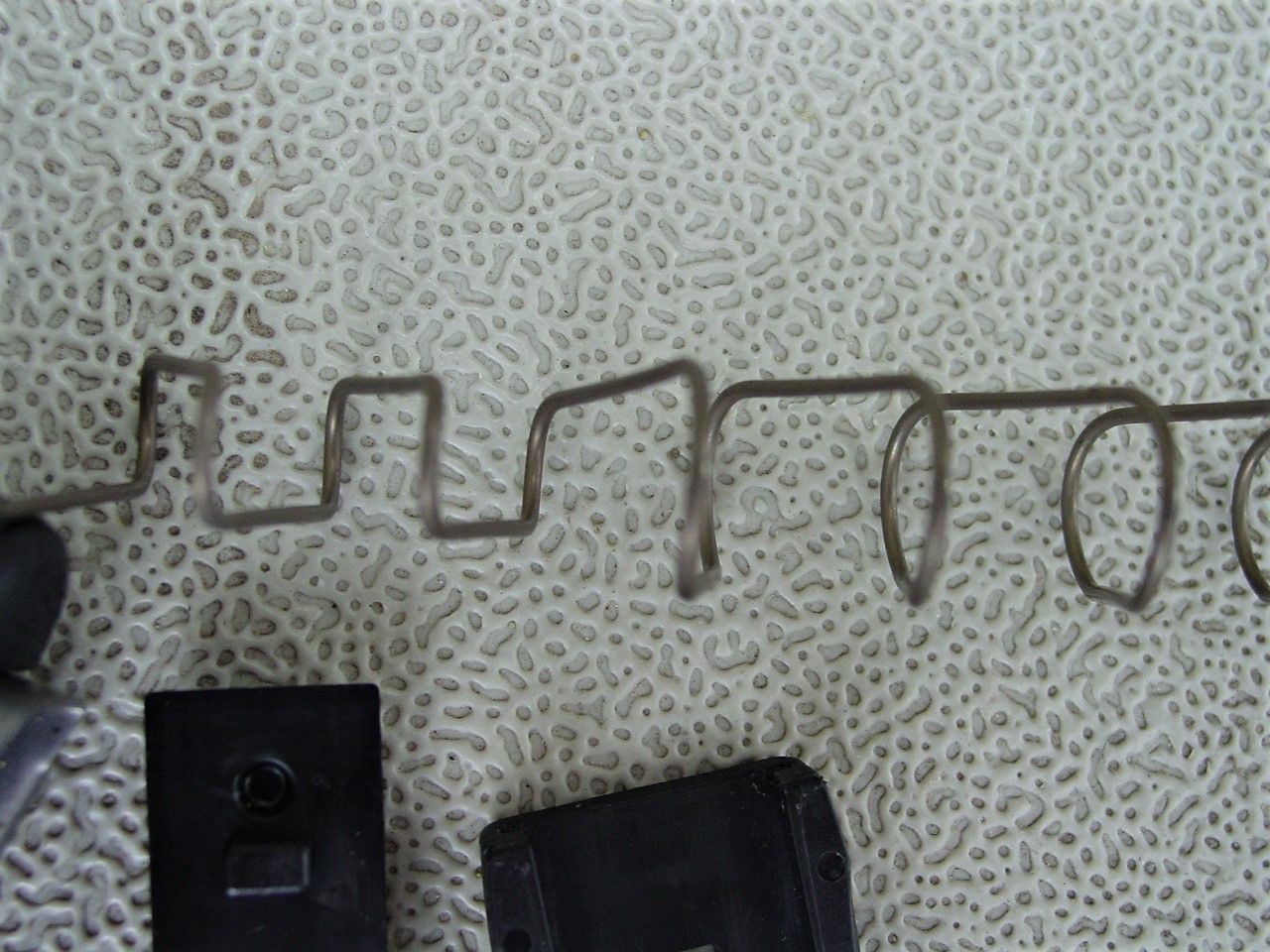

In the pic above, the spring above on the left, the top of the spring, the highest point, is in the correct orientation in relation to the follower and in relation to the mags. They have a forward orientation. The top faces forward, towards the front of the mag.

These springs have a big bottom and a smaller top. There is only one way to get them in the mag in that regard. The smaller end goes in first.

Like the magazine, the springs have a top and bottom and a front and a back. The top of the spring faces forward.

They is only one way to get them wrong and still fit in the mag body...the front of the spring is inserted incorrectly when it faces backward, towards the rear of the mag.

The spring on the right faces backward, the front faces the rear of the mag and the rear of the follower. A person could force them in this way. It would be clumsy to do but it could be done.

That would maybe cause another issue. See the pic below. When these springs face forward they are flat on the right hand side. Meaning that when placed flat on a flat surface only the right hand side lays flat. This means that the smaller portion of the springs is not centered to the main body of the spring. This won't make much difference in actual practice. But if you have it in backwards it might make it more liable to kink.

tipoc

Last edited: