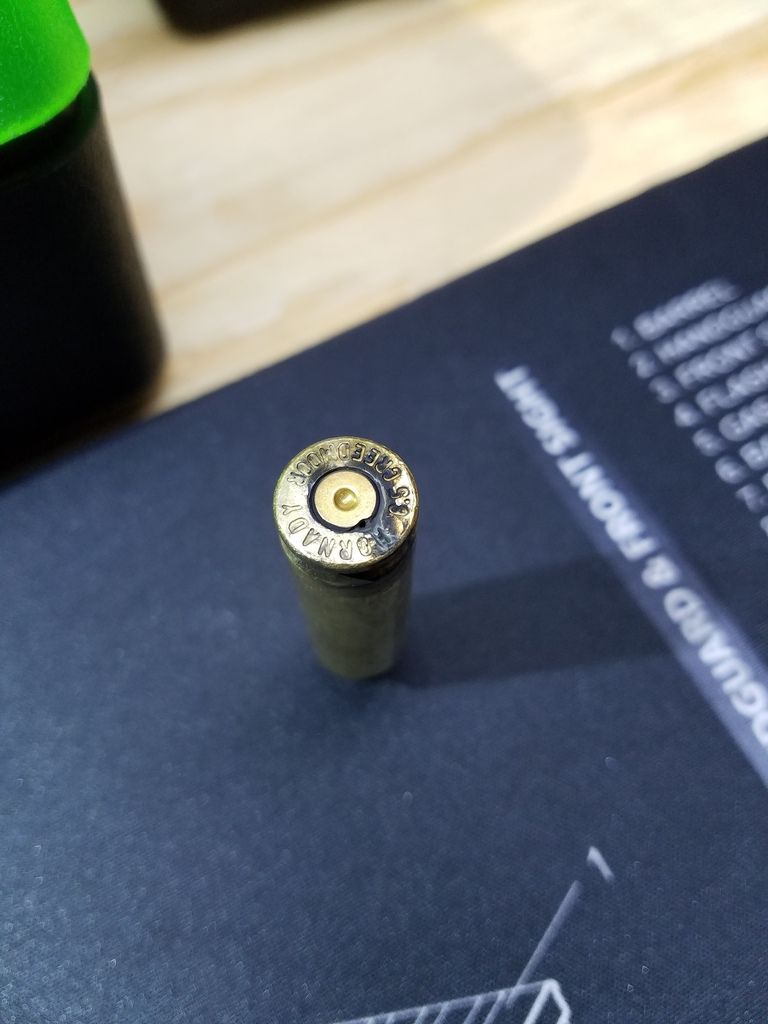

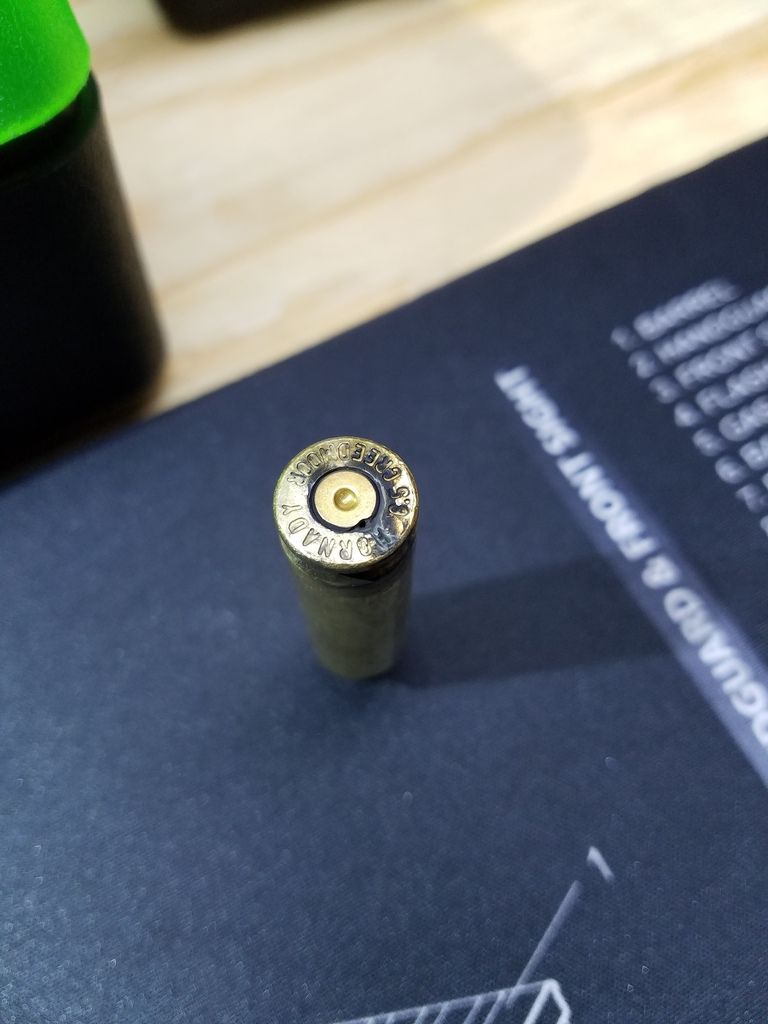

Still zeroing in this new RPR 6.5. Ordered some 6.5 hornady reloading brass, and some 143 grain ELD-X's. Had about 1/3 lb of Hodgdon Superperformer left over so I wanted to finish it off and loaded these up with 42.2 grains. COL set to 2.802"

40 of them fired just fine and the primers looked okay. This one fired, POI was about 4" higher than the rest of the group and I noticed a lot more smoke coming from ejection port and magwell. Pulled the case out and noticed the burn hole between the primer and the case, so I pulled the bolt and noticed that it burned a pit in that as well. Packed up and stopped for the day at least until I can figure out what caused this. Also, is the bolt junk now?

Any ideas welcome, somewhat new to reloading so I'm wanting to know what I did wrong here.

Thanks

{Edit: Can't show copyrighted materials on the board without permission from the copyright holder}

40 of them fired just fine and the primers looked okay. This one fired, POI was about 4" higher than the rest of the group and I noticed a lot more smoke coming from ejection port and magwell. Pulled the case out and noticed the burn hole between the primer and the case, so I pulled the bolt and noticed that it burned a pit in that as well. Packed up and stopped for the day at least until I can figure out what caused this. Also, is the bolt junk now?

Any ideas welcome, somewhat new to reloading so I'm wanting to know what I did wrong here.

Thanks

{Edit: Can't show copyrighted materials on the board without permission from the copyright holder}

Last edited by a moderator: