You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What are the reasons for powder coating?

- Thread starter salvadore

- Start date

Jump to post #64 and read a few from there

(It's on page 3)

Oh, and another reason... if you have a bunch of Lyman molds, ..... surely you have a couple/few that cast undersized by a thousandth or so. Now, with powdercoating, that's just what you want! PC adds .002 to the diameter and now you can cast, coat, and resize to that perfect fit.

(It's on page 3)

Oh, and another reason... if you have a bunch of Lyman molds, ..... surely you have a couple/few that cast undersized by a thousandth or so. Now, with powdercoating, that's just what you want! PC adds .002 to the diameter and now you can cast, coat, and resize to that perfect fit.

Last edited:

David Bachelder

New member

It allows the home bullet caster the ability to produce jacketed bullets. The Powder coat becomes the cast lead bullets jacket and replaces bullet lube.

Ok, so if I have a plain base mold like Lee's 45 255 rfp, that I run thru a .45 Colt rifle, I can skip the lubersizing process and powder coat as long as the final width works with the shooter. right?

Also I use a 358156 GC in a M-28 that is quite accurate when pushed hard, since I have to run it thru a sizer to set the gc anyway, would pc be worth worrying about?

Does it interfere with obturation in handguns?

Thanks for the info.

Also I use a 358156 GC in a M-28 that is quite accurate when pushed hard, since I have to run it thru a sizer to set the gc anyway, would pc be worth worrying about?

Does it interfere with obturation in handguns?

Thanks for the info.

I would size those bullets, no lube. Powder coat, and size again. Then load and shoot.

Powder coating is easy. PCed bullets are much cleaner to store, handle, and shoot. I have only been PCing for a few months but have never had any PCed bullet "fail". I have mostly used PC on my handgun bullets, 38/357, 9mm, .44 Mag., 45 ACP, but am trying some PCed .314" bullets in my Mosin Nagant. The performance, ie., expansion and accuracy, is the same as the cast bullets w/o a coating.

I would think the obturation is much less of concern with PCed than plain lead,as a good seal isn't needed as much. From what I've experienced and read, the bullet retains most of it's properties when PCed, like obturation, gripping the rifling, and expansion on target.

Powder coating is easy. PCed bullets are much cleaner to store, handle, and shoot. I have only been PCing for a few months but have never had any PCed bullet "fail". I have mostly used PC on my handgun bullets, 38/357, 9mm, .44 Mag., 45 ACP, but am trying some PCed .314" bullets in my Mosin Nagant. The performance, ie., expansion and accuracy, is the same as the cast bullets w/o a coating.

I would think the obturation is much less of concern with PCed than plain lead,as a good seal isn't needed as much. From what I've experienced and read, the bullet retains most of it's properties when PCed, like obturation, gripping the rifling, and expansion on target.

Last edited:

FrankenMauser

New member

Another bonus of powder coating, is that it lets you eliminate or substantially reduce lube grooves, eliminate gas checks, and create much more compact bullets (all else being equal). As such, you get bullets that are more easily stabilized by slower rifling twist rates, and more case capacity.

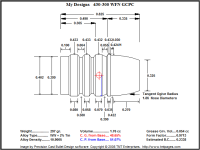

Here's an example, using 300 gr WFN bullets designed for a short-throated .444 Marlin levergun:

First, a 'standard' version designed for a Hornady gas check.

You end up with a finished weight of about 307 gr (w/ GC and lube), and a seating depth of 0.507" (GC adds 0.017").

(.432-.433" final diameter)

Note: This design is already quite 'compact' for a .44 caliber 300 WFN. Most designs have more taper in the nose and larger lube grooves, making the bullet even longer than this example.

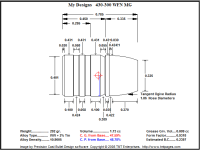

But as a PC bullet, the seating depth shrinks to 0.452" (about 0.002" of coating added to base), increasing case capacity by about 0.5 gr (depending on powder choice). Finished weight would be about 304 gr, with a higher theoretical ballistic coefficient than the standard bullet.

Everything from the crimp groove forward remains the same. The only changes are to the body and shank.

(.432" final diameter)

Here's an example, using 300 gr WFN bullets designed for a short-throated .444 Marlin levergun:

First, a 'standard' version designed for a Hornady gas check.

You end up with a finished weight of about 307 gr (w/ GC and lube), and a seating depth of 0.507" (GC adds 0.017").

(.432-.433" final diameter)

Note: This design is already quite 'compact' for a .44 caliber 300 WFN. Most designs have more taper in the nose and larger lube grooves, making the bullet even longer than this example.

But as a PC bullet, the seating depth shrinks to 0.452" (about 0.002" of coating added to base), increasing case capacity by about 0.5 gr (depending on powder choice). Finished weight would be about 304 gr, with a higher theoretical ballistic coefficient than the standard bullet.

Everything from the crimp groove forward remains the same. The only changes are to the body and shank.

(.432" final diameter)

Attachments

i wasnt sure where i was going to post this, but you asked at a good time, i have just started powdercoating and i am so impressed with the cleanliness, the ability to shoot faster, softer lead and NO smoke

i just built a 300blk a couple weeks ago and shot some lead bullets through it that were not powdercoated and it was a liquified leaded mess, i tried again with the same loads coated and it worked flawlessly even supersonic

so tomorrow i am going out with 300 bullets, 100 ALOX, 100 powdercoat and 100 plated, alll 124gr 9mm loaded with 4,2gr of HP-38; all bullets were seated to same and post sized

i will be testing velocity, groups @ 10-25-50 and rapid fire to see which leaves me the least build-up and if accuracy is improved or diminished with PC; ill report back sunday with results

all i can say is when it comes to cleaning your gun and having a true smokeless lead-cast round and powdercoating is easier, faster and cleaner than regular lube, so far i absolutely love it

i recommend trying it out for yourself and making your own judgement; less than 40$ to get started up

i just built a 300blk a couple weeks ago and shot some lead bullets through it that were not powdercoated and it was a liquified leaded mess, i tried again with the same loads coated and it worked flawlessly even supersonic

so tomorrow i am going out with 300 bullets, 100 ALOX, 100 powdercoat and 100 plated, alll 124gr 9mm loaded with 4,2gr of HP-38; all bullets were seated to same and post sized

i will be testing velocity, groups @ 10-25-50 and rapid fire to see which leaves me the least build-up and if accuracy is improved or diminished with PC; ill report back sunday with results

all i can say is when it comes to cleaning your gun and having a true smokeless lead-cast round and powdercoating is easier, faster and cleaner than regular lube, so far i absolutely love it

i recommend trying it out for yourself and making your own judgement; less than 40$ to get started up

I've said it before, this forum is a cornucopia of info. I'm sure these questions have been addressed in other posts by Beagle et al, but if wouldn't mind answering a few other ?s.

1. Is the pc toxic, can I use my kitchen oven? What temp and how long? Where do I purchase pc material?

2. If I have a .314 pc bullet and run it thru a .312 die will the pc remain?

3. Is regular aluminum foil an appropriate material for heating the pc bullets on?

4. I push a .314/.313 gc bullet out of my Marlin 32/20 @ 1850fps+ with little or no leading. I have a PB bullet of similar configuration. Will the PCed base act like a GC on the PB bullet?

I don't mean to be a pita, but any help would be appreciated.

1. Is the pc toxic, can I use my kitchen oven? What temp and how long? Where do I purchase pc material?

2. If I have a .314 pc bullet and run it thru a .312 die will the pc remain?

3. Is regular aluminum foil an appropriate material for heating the pc bullets on?

4. I push a .314/.313 gc bullet out of my Marlin 32/20 @ 1850fps+ with little or no leading. I have a PB bullet of similar configuration. Will the PCed base act like a GC on the PB bullet?

I don't mean to be a pita, but any help would be appreciated.

Sal,

I will try to help.

"1. Is the pc toxic, can I use my kitchen oven? Most would council not to. You are still dealing with 'lead' and the polymers do vent gasses during the process. What temp and how long? This is both determined by the powder and your process. 325 to 425 degrees are the general spread, 400 degrees is standard and curing time is 12 minuets up. Where do I purchase pc material? Every place. 'Harbor Freight' is cheap (the RED is the best). I like 'Powder By The Pound', a little higher cost but more colors than I can name. (It helps that my brother lives 15 miles from them.)

2. If I have a .314 pc bullet and run it thru a .312 die will the pc remain? I have found that the lead will give it up before the polyester. I size my 44s (430) before and after coating, others do it only once.

3. Is regular aluminum foil an appropriate material for heating the pc bullets on? No, get the 'Non-Stick' stuff.

4. I push a .314/.313 gc bullet out of my Marlin 32/20 @ 1850fps+ with little or no leading. I have a PB bullet of similar configuration. Will the PCed base act like a GC on the PB bullet?" I push 130 grain flat base out of a 300 Blackout at 2070 FPS with no problems, The best I do with 125 grain jacketed is 2120 FPS with full function and no pressures. Some think a GC bullet looses accuracy when no GC is installed.

The process is simple and I think delivers much better results over faster [rifle speeds] lead loads with much less effort on my part.

OSOK

I will try to help.

"1. Is the pc toxic, can I use my kitchen oven? Most would council not to. You are still dealing with 'lead' and the polymers do vent gasses during the process. What temp and how long? This is both determined by the powder and your process. 325 to 425 degrees are the general spread, 400 degrees is standard and curing time is 12 minuets up. Where do I purchase pc material? Every place. 'Harbor Freight' is cheap (the RED is the best). I like 'Powder By The Pound', a little higher cost but more colors than I can name. (It helps that my brother lives 15 miles from them.)

2. If I have a .314 pc bullet and run it thru a .312 die will the pc remain? I have found that the lead will give it up before the polyester. I size my 44s (430) before and after coating, others do it only once.

3. Is regular aluminum foil an appropriate material for heating the pc bullets on? No, get the 'Non-Stick' stuff.

4. I push a .314/.313 gc bullet out of my Marlin 32/20 @ 1850fps+ with little or no leading. I have a PB bullet of similar configuration. Will the PCed base act like a GC on the PB bullet?" I push 130 grain flat base out of a 300 Blackout at 2070 FPS with no problems, The best I do with 125 grain jacketed is 2120 FPS with full function and no pressures. Some think a GC bullet looses accuracy when no GC is installed.

The process is simple and I think delivers much better results over faster [rifle speeds] lead loads with much less effort on my part.

OSOK

i don't know about toxic, you def wil not be vaporizing lead into fumes at a mere 350-400 degrees. BUT, you will never get the smell of powder-coat out of your oven/kitchen. must be done outdoors, it is very stinky. the oven costs 17.99 at Wal-Mart and they had some even cheaper. not worth all your food tasting like paint for the next year for 17$

I'm not sure how it compares, but the sweetie hit the auto clean on the oven a few weeks back, only to discover that somehow she had left a plastic handled spatula in there. If it is worse than that no way, as that is still screwing up the kitchen when we light the oven off.

If it is worse than that no way, as that is still screwing up the kitchen when we light the oven off.

So might be a blessing in disguise for me huh...

So might be a blessing in disguise for me huh...

I concur with 'skizzums' that lead remains in a solid state or not overly plastic state at most temps below 450 degrees but there are some things I just don't think suitable. I wouldn't pick up a newly cast lead bullet and start shewing on it. Nor do I think bringing lead into my cooking area is the correct thing to do.

With that covered, look at entry number 17 in this thread. The photo should provided ample reason to NOT use the kitchen stove.

http://castboolits.gunloads.com/sho...es-and-danger-(or-the-lack-of)-from-baking-PC

Enjoy while you can,

OSOK

With that covered, look at entry number 17 in this thread. The photo should provided ample reason to NOT use the kitchen stove.

http://castboolits.gunloads.com/sho...es-and-danger-(or-the-lack-of)-from-baking-PC

Enjoy while you can,

OSOK

Fear not ye breatheren of the silver stream, three will be NO powder coating in the kitchen stove... Nor would I put a tray of bullets in there to harden up either.

Nor would I put a tray of bullets in there to harden up either.

There are times in life when a man has to know his limitations, and well I know mine.

That said the old giant oven we had when I was growing up, well it had many uses. Pop used it to heat up barreled actions for blueing, along with scores of other scientific projects. Once we got a pan full of paraffin a touch hot and it lit off. Whoo Haaa, that was some fun right there for sure and certain. Nothing was hurt, injured, or permanently maimed, but there was plenty of shall we just say, "words" flying around for sure.

Nope but no powder coating in the house. But having heard of the smells, and as sensitive as I am to them I might not even do it out in the shop either. Plastic smells really work on me for some reason or another, and one thing I cannot stand is a roll of that clear poly. I can smell that stuff 30yds away. Whew what a stinch.

There are times in life when a man has to know his limitations, and well I know mine.

That said the old giant oven we had when I was growing up, well it had many uses. Pop used it to heat up barreled actions for blueing, along with scores of other scientific projects. Once we got a pan full of paraffin a touch hot and it lit off. Whoo Haaa, that was some fun right there for sure and certain. Nothing was hurt, injured, or permanently maimed, but there was plenty of shall we just say, "words" flying around for sure.

Nope but no powder coating in the house. But having heard of the smells, and as sensitive as I am to them I might not even do it out in the shop either. Plastic smells really work on me for some reason or another, and one thing I cannot stand is a roll of that clear poly. I can smell that stuff 30yds away. Whew what a stinch.

PC will handle sizing and it will not damage the coating. It makes it so slippery that you'll want to get out your mic and double check that your die actually sized anything. It just slips right through easily. For an extreme sizing example, there are a number of us sizing the .462 Hammer (A big MiHec HP meant for the .45-70) down to .452 for our .45LCs. It's a two step size, once from .462 to .457, then again through the .452 die and they look perfect afterward. PC is melted polyester, it is very flexible. And it is just a thin coat, 1/1000 of an inch thick. You can smash the bullet flat with a hammer and it'll stay on there. (by the way, smashing is one of the most popular tests to see if you are curing it properly.)

Since it is just a thin coat of polyester, it is not a gas check. You can shoot some gas check bullets at medium velocities without a gas check, just as you could with a regular lubed bullet that was fitted correctly to your gun, but if you want to apply full power, that little thin coat of plastic isn't going to stop gas cutting at high pressure. It isn't as tough as a metal gas check.

A lot of guy are enjoying shooting their .30-30s and .223s without checks for target shooting though. Try it and you'll find out how fast you can go unchecked. It should be faster than with regular lube... but not up to the book maximum on the loads.

Since it is just a thin coat of polyester, it is not a gas check. You can shoot some gas check bullets at medium velocities without a gas check, just as you could with a regular lubed bullet that was fitted correctly to your gun, but if you want to apply full power, that little thin coat of plastic isn't going to stop gas cutting at high pressure. It isn't as tough as a metal gas check.

A lot of guy are enjoying shooting their .30-30s and .223s without checks for target shooting though. Try it and you'll find out how fast you can go unchecked. It should be faster than with regular lube... but not up to the book maximum on the loads.