I have gone through every page of the American Rifleman magazine, from WW2 onward, and I recall one derogatory Dope Bag letter over the Krag metallurgy and heat treatment. It is my recollection that the author claimed the Krag bolts were “flame hardened” and generally he expressed a low opinion of the metallurgical quality. It must be understood that between the wars, Government Arsenals were just as underfunded as the rest of the military. The parsimony of Congress, combined with a “kick the can down the road” attitude of military leadership meant that the Arsenals went through boom and bust cycles, with the bust cycles lasting decades. During the lean years, equipment became outdated, Arsenals would always be behind technological advancements.So why didn't Krags "blow up"? Some did, and bolts were brittle.

Colt Firearms had the same problem in the 70’s, 80’, 90’s, etc, as the company owners took profits out, but did not put funding back in. We all have seen this in Colt firearms of the period.

I am of the opinion that the single heat treat issue was finally raised in the late 20’s, and by Springfield Armory. I have no proof, but by the late 20’s I do not see a military need for more 03’s. There were 2.5 million M1917’s in storage, future production of a semi automatic replacement was years, if not decades off, and considering the ideas of “endless prosperity” and the “war to end all wars” attitudes of the times, I believe Springfield Armory was under the threat of a real shut down. An order for 1,000,000 new 03’s would have been just the ticket. As it was, we know an independent board was established, and it makes sense, because if this was started by SA, any investigation would have had to have been taken out of their hands, given that they would have had a financial benefit in the matter. So this is my pie in the sky conspiracy. Springfield Armory was perfectly placed, as they had all the data, to make a case that all low number rifles should be scrapped, and replaced with new rifles.

Hatcher would have us believe that unicorn sightings were more common than single heat treat receiver failures. I do not believe this, as this individuals testimony reveals that 03 blowups were far more common than Hatcher has lead us to believe.

From Arms and the Man, 1917 “In Defense of “the Short Gun”. By Captain James H. Keough

I can attest, by having experienced the misfortune of blowing both locking lugs from the bolt of my service rifle in the 900 yard state of the Leech Cup Match at Camp Perry in 1913, which fortunately did me no more harm than to record a goose egg for my first record shot at this distance, forcing me from the match and putting me out of the running for the Palma Team. The shock of the blow-back had no serious effect on my nervous system, as I was well hardened to the echo of the boiler shop (as the shed in which the International Meter Matchers were held was dubbed) by being a daily constant in the several matches. On this same day on which this accident occurred a team mate, Col Sergt Leary, of the Massachusetts Infantry, had a similar accident, but was slightly bruised about the face. The cause of these blow-ups was attributed to the bolts being too hard or burned in the case hardening process. Last year at the annual encampment of the 6th Massachusetts Infantry, at Martha’s Vineyard, a blow-black put a sergeant of one of the companies in the hospital for a week and nearly cost him the loss of one eye, and I know of another case nearby when two bad accidents occurred in one afternoon, the rifles being blown to pieces in both instances and one of the men having the side of his face torn away. These are the only cases that I recall as having happened in my locality or where I was at the time. Records of many others are well known, so that perhaps there is some cause for this alarm as to the safety of the (M1917) Enfield, which we all know*, is not as strong as the US Magazine rifle…

* Information had not reached the shooting community that the 1917 Enfield was a different action from the SMLE. Very shortly after this article was published, B. Gen Fred Phillips wrote an editiorial stating the Offical Army position on this matter.

Arms and the Man, Brig Gen Fred H. Phillips Jr 1917

Blown Blots and Split Barrels

Recently there have been reported from rifle clubs several cases where the barrels of Army rifles have burst and where bolts have blown out.

To those who are not familiar with the circumstances attending these accidents-none of which fortunately have cost human life- the mishaps have suggested that possibly the Springfield rifle is an unsafe arm, and that practice with it may be attended by fatalities.

The truth of the matter is that the Springfield is quite as safe as any high powered rifle, and possibly a much more reliable gun than one could expect from a weapon the charge of which exerts 50,000 pounds per square inch pressure in the chamber. The reason why one hears more of “blow-ups’ in the Springfield is that more rifle club members use this arm than use any other one make of commercial weapon, and consequently, in point of number, although not necessarily in point of numbers, although not necessarily in point of percentage, the accidents from the military type rifle may appear greater.

Emphatically the Springfield is not an unsafe gun. As it comes from the arsenal, it can be used year in and year out and so far as the likelihood of accidents is concerned, be as good as ever-but provide that it is properly handled and properly cared for.

If one takes the trouble to inquire into the causes of accidents with the Springfield, it will more than likely result in the conclusion that 99 our of 100 mishaps such as blown bolts and split barrels result either from the use of hand-loads or special loads improperly or carelessly put together in the making, greased chambers, or both.

In short, there nothing the matter with the Springfield as long as it is used for the ammunition for which it was designed, except of course in the very small percentage of cases where a bolt has been over hardened or some similar mechanical defect has crept in during manufacture.

This official Army position came out after the receiver blow up’s at National Copper and Brass, which lead to a shut down of the Springfield Armory production lines. I consider this a coverup. The Army, in print, is deigning they have a rifle problem. Given that the B Gen who wrote this was a General in the pre War Regular Army, and not some Johnny come lately, he is an extremely powerful and well placed individual. After this the Army never again published an account of a blown up 03 unless the author claimed the blow up was due to his personnel negligence.To those who are not familiar with the circumstances attending these accidents-none of which fortunately have cost human life- the mishaps have suggested that possibly the Springfield rifle is an unsafe arm, and that practice with it may be attended by fatalities.

The truth of the matter is that the Springfield is quite as safe as any high powered rifle, and possibly a much more reliable gun than one could expect from a weapon the charge of which exerts 50,000 pounds per square inch pressure in the chamber. The reason why one hears more of “blow-ups’ in the Springfield is that more rifle club members use this arm than use any other one make of commercial weapon, and consequently, in point of number, although not necessarily in point of numbers, although not necessarily in point of percentage, the accidents from the military type rifle may appear greater.

Emphatically the Springfield is not an unsafe gun. As it comes from the arsenal, it can be used year in and year out and so far as the likelihood of accidents is concerned, be as good as ever-but provide that it is properly handled and properly cared for.

If one takes the trouble to inquire into the causes of accidents with the Springfield, it will more than likely result in the conclusion that 99 our of 100 mishaps such as blown bolts and split barrels result either from the use of hand-loads or special loads improperly or carelessly put together in the making, greased chambers, or both.

In short, there nothing the matter with the Springfield as long as it is used for the ammunition for which it was designed, except of course in the very small percentage of cases where a bolt has been over hardened or some similar mechanical defect has crept in during manufacture.

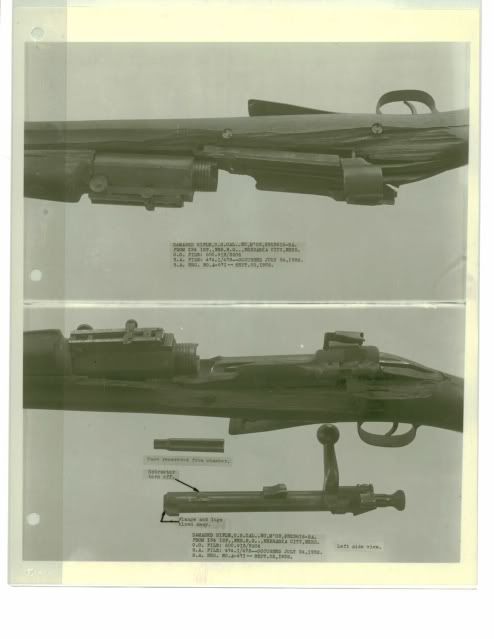

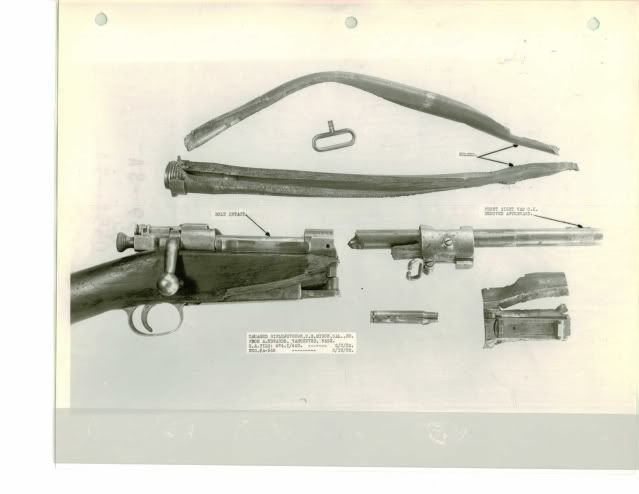

As for after Hatcher’s List, these images came from the Springfield Armory web collection. Just go to their web site and brose.

Blown up 1932

Receiver 323816

Receiver 570, 095 Blown up 1932

1931 Receiver 718, 233

Receiver 764, 040 blown 1931